89

8017171/115Z/V3-0/2019-01/ SICK OPERATING INSTRUCTIONS | VISIC100SF

Subject to change without notice

MAINTENANCE

8.3 Maintenance

8.3.1 VISIC100SF maintenance

Regular maintenance: 1 x year.

8.3.1.1 Clean device inside and outside

▸ Clean the outside of the VISIC100SF with a damp cloth before opening.

▸ Ensure the air inlet openings are not blocked.

▸ Clean the inside of the cover.

▸ Then carefully clean the inside of the device with a clean cloth.

8.3.1.2 Clean optics

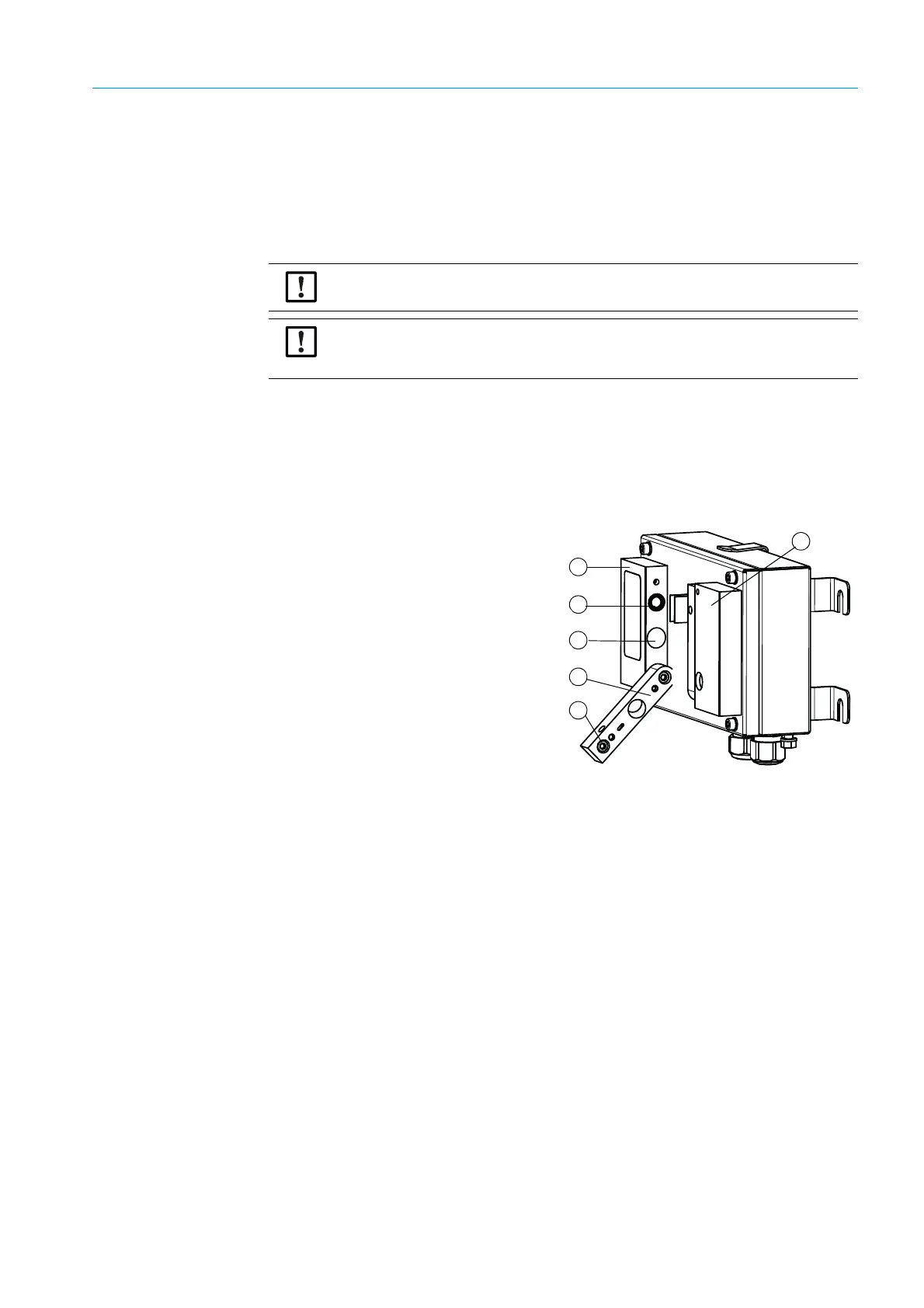

Fig. 86: Cleaning optical interfaces

1 Loosen cylinder screw (6) at the upper end of the protective tube.

2 Open the protective tube.

3 Clean the optical interfaces and optical beam path in the protective tube with a cotton

swab.

4 Close the protective tube and fasten the cylinder screw again.

5 Repeat the procedure on the opposite side.

6 Clean the light trap.

8.3.1.3 Visibility test with VIS test tool

Two K-value test tools are available to check the visibility value.

● One test tool in value range k = 0 ... 7/ km (test set, Part No.2071542)

● One test tool in value range k = 7 ... 15/ km (test set, Part No.2071541)

NOTE: Avoid contamination of the measuring unit when opening

▸ Clean outer surfaces of device before opening.

NOTE: Preventive measures against ESD

Maintenance of the VISIC100SF may only be carried out by a skilled technician.

▸ Observe the applicable ESD Guidelines.

5

4

1

3

2

6

Tools required

1 x Allen key

(ball head SW4)

1 x cotton swab

Receiver unit

Sender unit

Aperture

Light trap

Protective tube

Cylinder screw M5

Loading...

Loading...