Instructions

9.4 PID basic functions

PID control

Function Manual, 03/2017, A5E35300227-AC

505

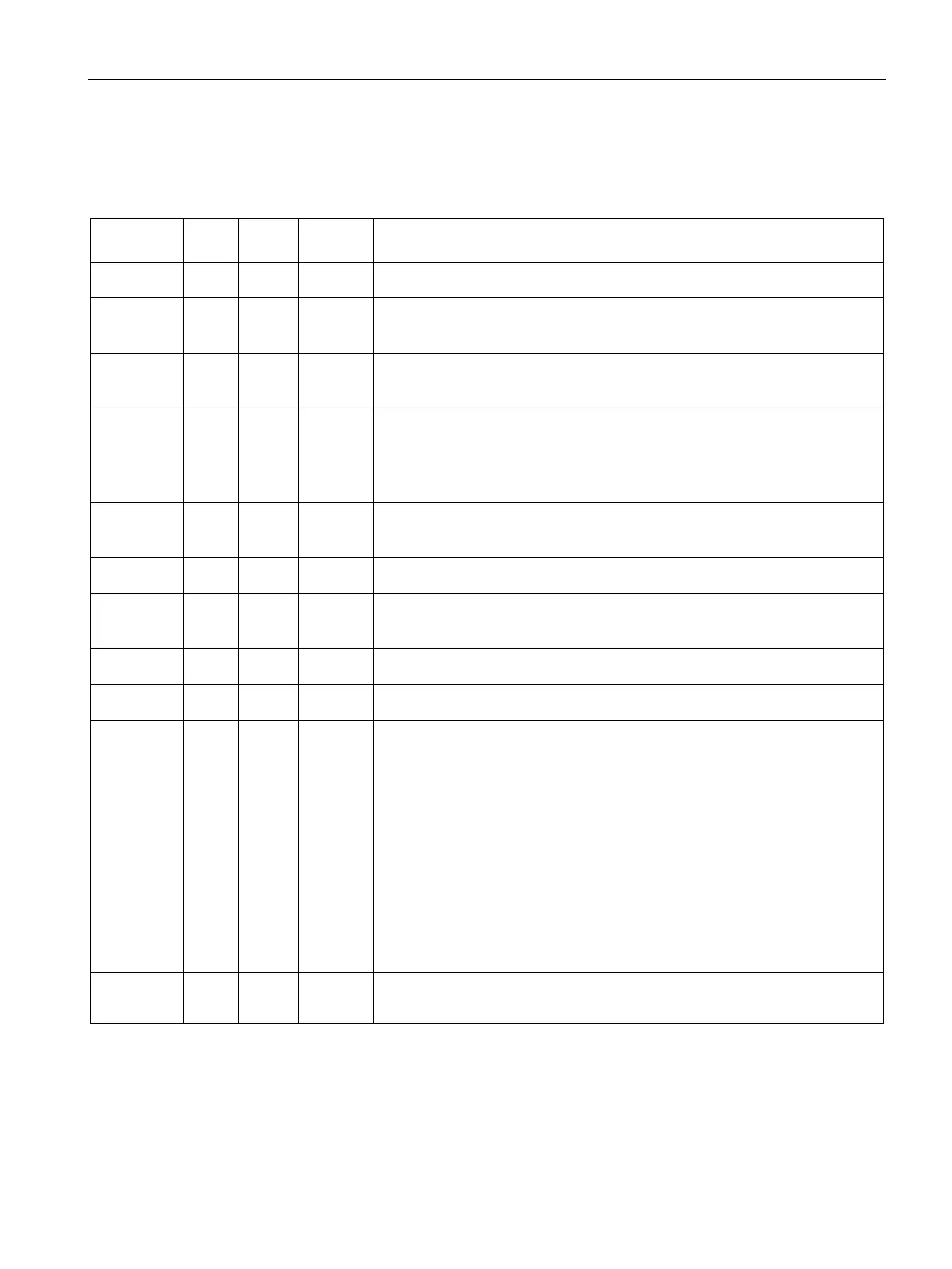

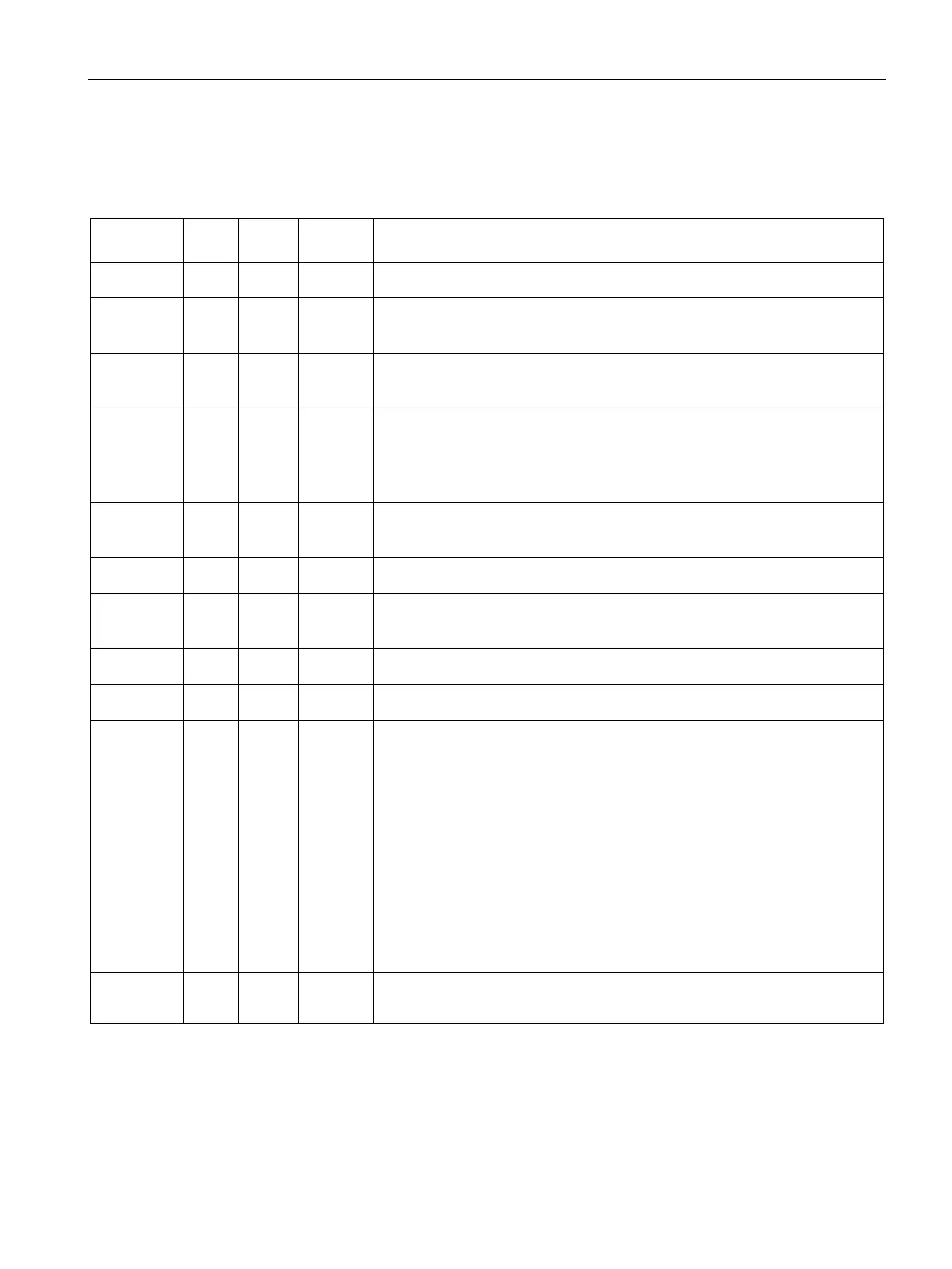

Table 9- 26 Static variables TCONT_S

The "Process value factor" input is multiplied by the process value. The input

is used to scale the process value range.

PV_OFFS 36.0 REAL 0.0 The input "Process value offset" is added to the process value. The input is

used to scale the process value range.

The valid values depend on the sensors used.

A deadband is applied to the control deviation. The "Deadband width" input

determines the size of the deadband.

PFAC_SP 44.4 REAL 1.0 PFAC_SP specifies the effective P-action when there is a setpoint change.

• 1: P-action has full effect if the setpoint changes.

• 0: P-action has no effect if the setpoint changes.

Values from 0.0 to 1.0 are permitted.

The "Proportional gain" input specifies controller amplification. The direction of

control can be reversed by giving GAIN a negative sign.

The "Integration time" (integral-action time) input defines the integrator's time

response.

The runtime from endstop to endstop of the control valve is entered at the

"Motor actuating time" parameter.

A minimum pulse time can be configured at the "Minimum pulse time" param-

eter.

BREAK_TM 64.0 REAL 0.0 s You can assign a minimum break time at the parameter "Minimum break

PER_MODE 68.0 INT 0 You can use this switch to enter the type of I/O module. The process value at

input PV_PER is then scaled as follows at the PV output.

• PER_MODE = 0: Thermoelements; PT100/NI100; standard

PV_PER * 0.1

Unit: °C, °F

• PER_MODE = 1: PT100/NI100; climate

PV_PER * 0.01

Unit: °C, °F

• PER_MODE = 2: Current/voltage

PV_PER * 100/27648

If the process value is to be read in from the I/Os, the PV_PER input must be

interconnected with the I/Os and the "Enable process value I/Os" input must

Block diagram TCONT_S (Page 501)

Loading...

Loading...