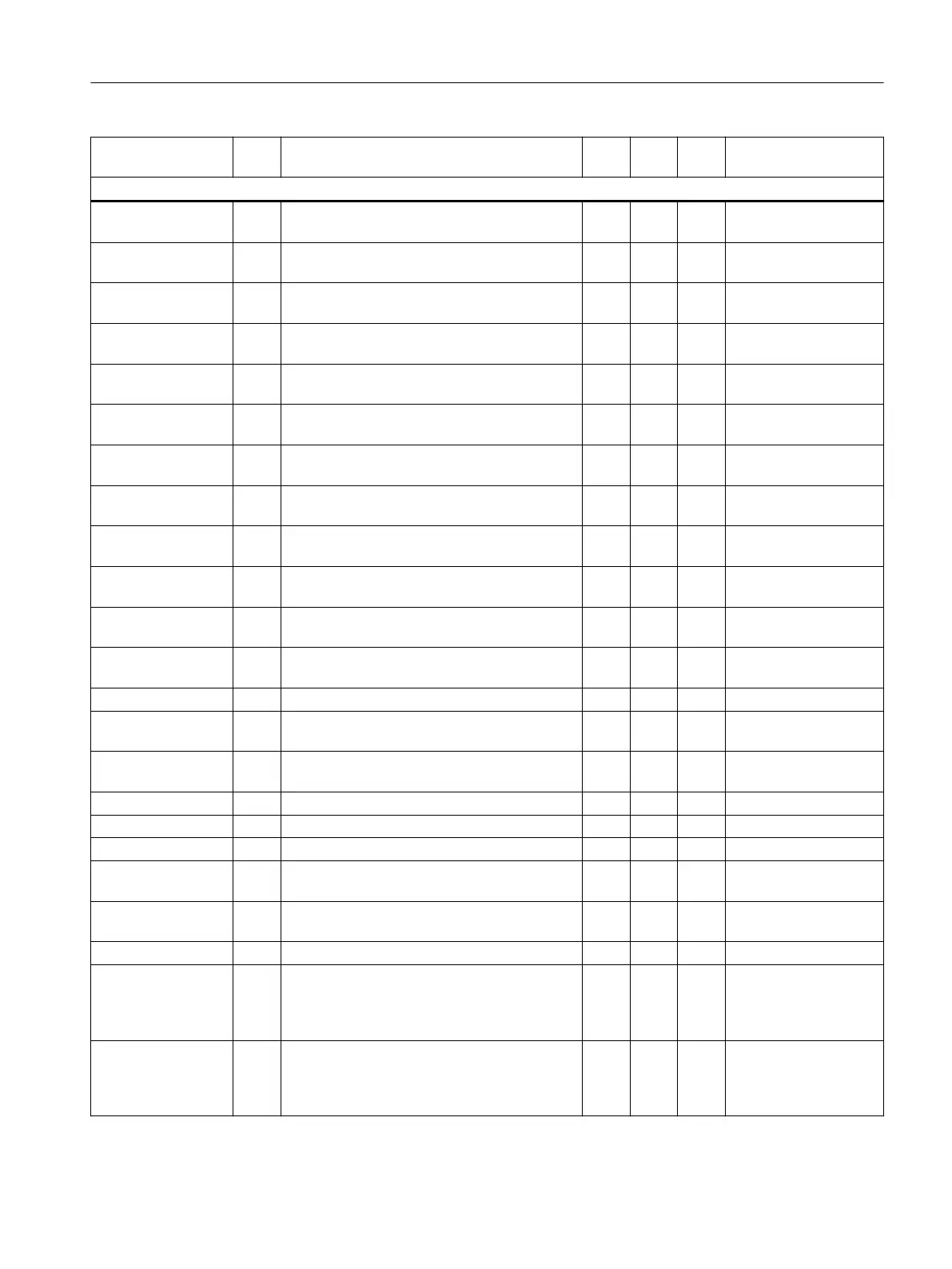

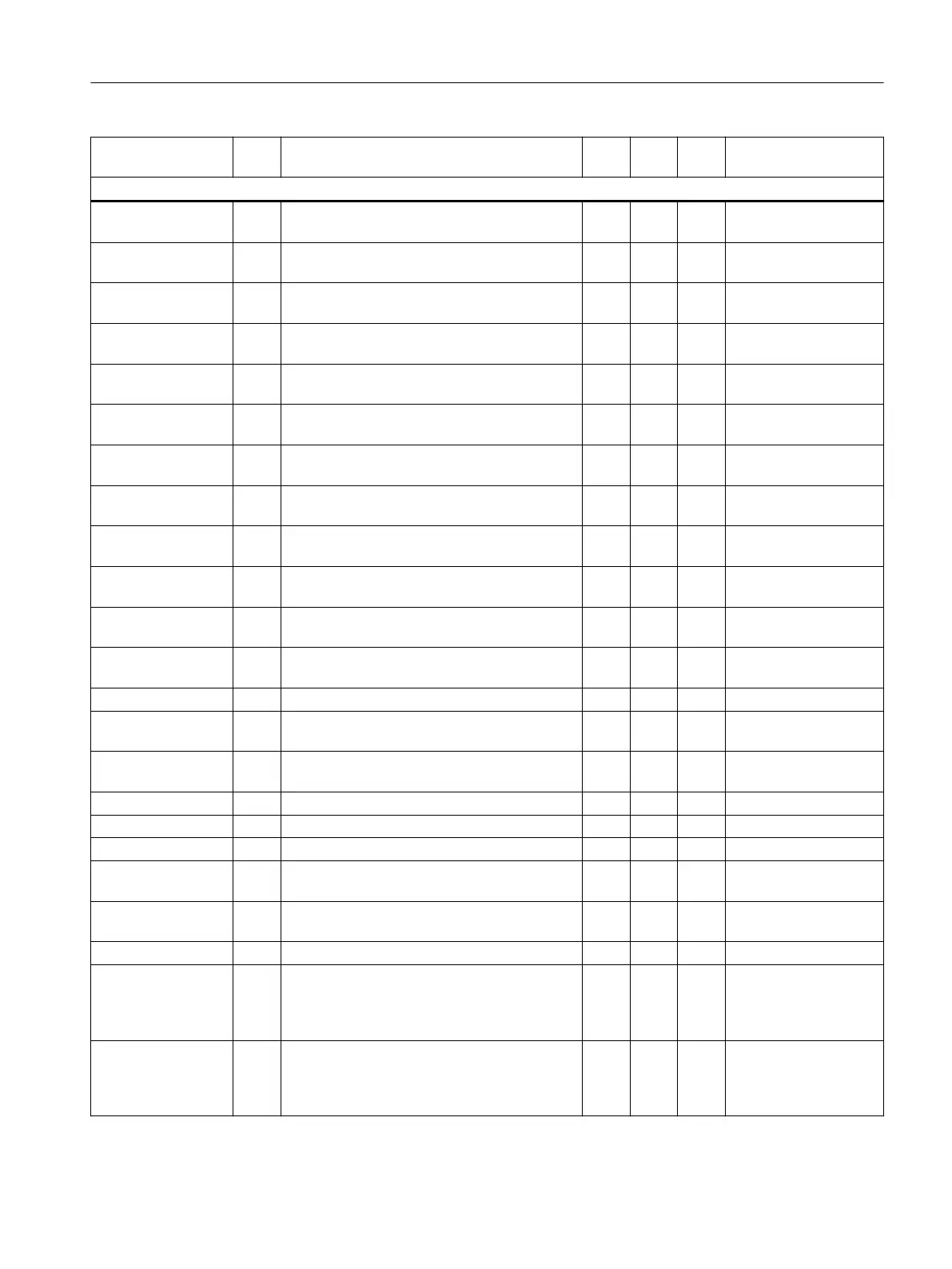

Operation Type

1)

Meaning W

2)

TP

3)

SA

4)

Description see

5)

1) 2) 3) 4) 5)

for explanations, see legend (Page 1197).

CTABPOL F Number of polynomials already used in the

memory

+/- +/- PM-NC

CTABPOLID F Number of the curve polynomials used by the

curve table with number n

+/- +/- PM-NC

CTABSEG F Number of curve segments already used in

the memory

+/- +/- PM-NC

CTABSEGID F Number of the curve segments used by the

curve table with number n

+/- +/- PM-NC

CTABSEV F Returns the end value of the following axis of

a segment of the curve table

+/- +/- PM-NC

CTABSSV F Returns the starting value of the following axis

of a segment of the curve table

+/- +/- PM-NC

CTABTEP F Returns the value of the leading axis at the

end of the curve table

+/- +/- PM-NC

CTABTEV F Returns the value of the following axis at the

end of the curve table

+/- +/- PM-NC

CTABTMAX F Returns the maximum value of the following

axis of the curve table

+/- +/- PM-NC

CTABTMIN F Returns the minimum value of the following

axis of the curve table

+/- +/- PM-NC

CTABTSP F Returns the value of the leading axis at the

start of the curve table

+/- +/- PM-NC

CTABTSV F Returns the value of the following axis at the

start of the curve table

+/- +/- PM-NC

CTABUNLOCK P Revoke delete and overwrite lock +/- +/- PM-NC

CTOL A Contour tolerance for compressor functions,

orientation smoothing and smoothing types

m +/- - PM-NC

CTOLG0 A Contour tolerance for rapid traverse move‐

ments

m +/- - PM-NC

CTRANS F Work offset for multiple axes +/- - PM-NC

CUT2D

6)

G 2D TRC m +/- PM-NC

CUT2DD G 2½ D TRC in relation to the differential tool m +/- PM-NC

CUT2DF G 2D TRC relative to the current frame (inclined

plane)

m +/- PM-NC

CUT2DFD G 2½D TRC in relation to a differential tool rela‐

tive to the current frame (inclined plane)

m +/- PM-NC

CUT3DC G 3D TRC for circumferential milling m +/- PM-NC

CUT3DCC G 3D TRC for circumferential milling taking into

account a limitation surface with 3D radius

compensation Contour on the machining sur‐

face

m +/- PM-NC

CUT3DCCD G 3D TRC for circumferential milling taking into

account a limitation surface with differential

tool on the tool center-point path: Infeed to the

limitation surface

m +/- PM-NC

Tables

4.1 Operations

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1205

Loading...

Loading...