SWDM40 OPERATION & MAINTENANCE MANUAL

7.1.5 Maintenance for Kelly

Maintenance can help users to find problem in advance, reducing the possibility occur in the

operation. It’s really an effective measure for ensuring construction efficiency.

After Kelly has been used for 50 hours or piled for 150m, please disassemble it to take the

initial maintenance. After used for 200 hours, take the maintenance for the second time, and

after that maintain it once every 500 hours. Any abnormal is found during operation, stop

working at once and disassemble the Kelly to repair. Besides, maintenance should be done after

changing the working site.

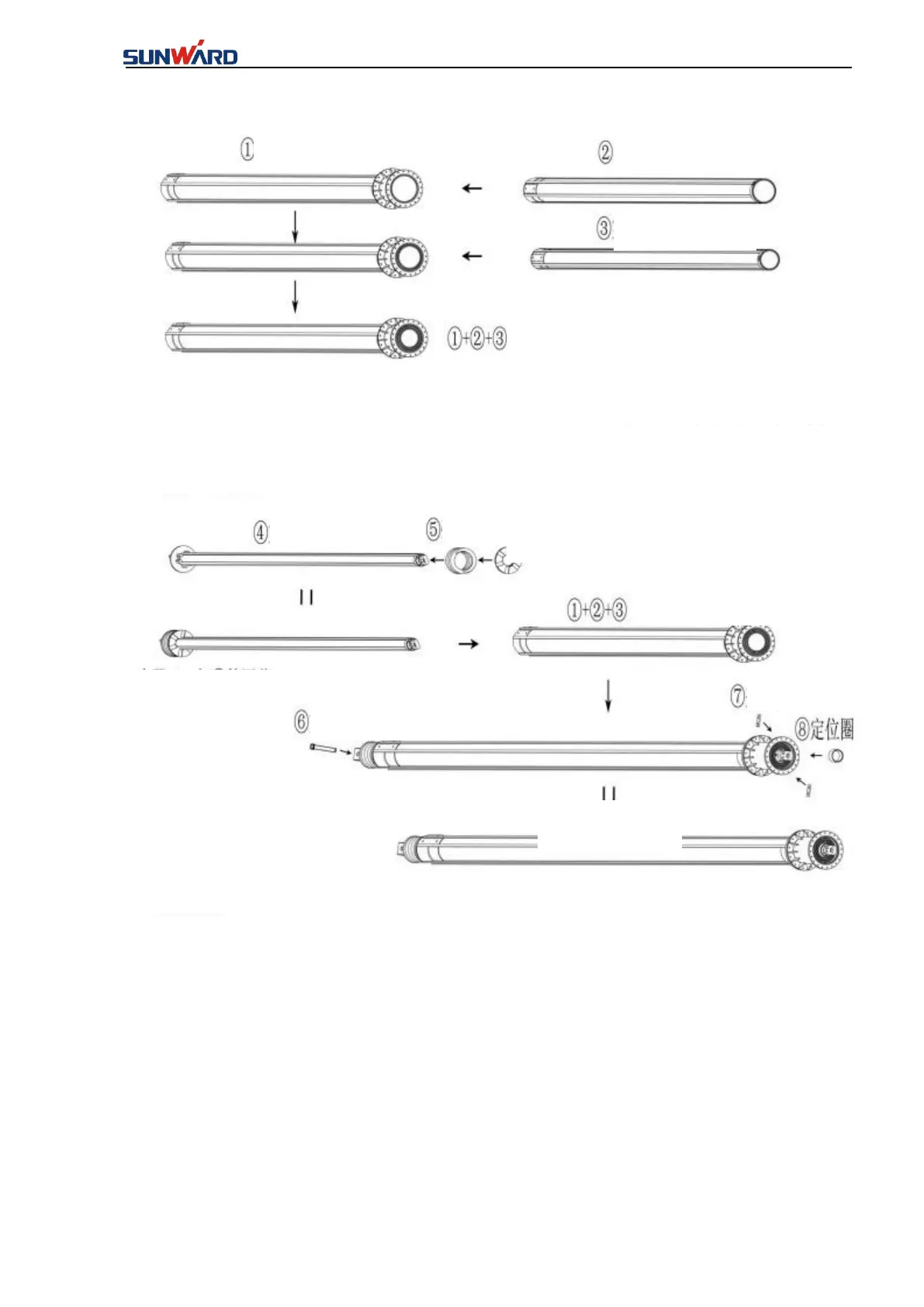

Step 1: Cushion the 1

st

section with crosstie on the

ground, assemble the 2

nd

section through the 1

st

section

center, and then assemble the 3

rd

section through 2

nd

section.

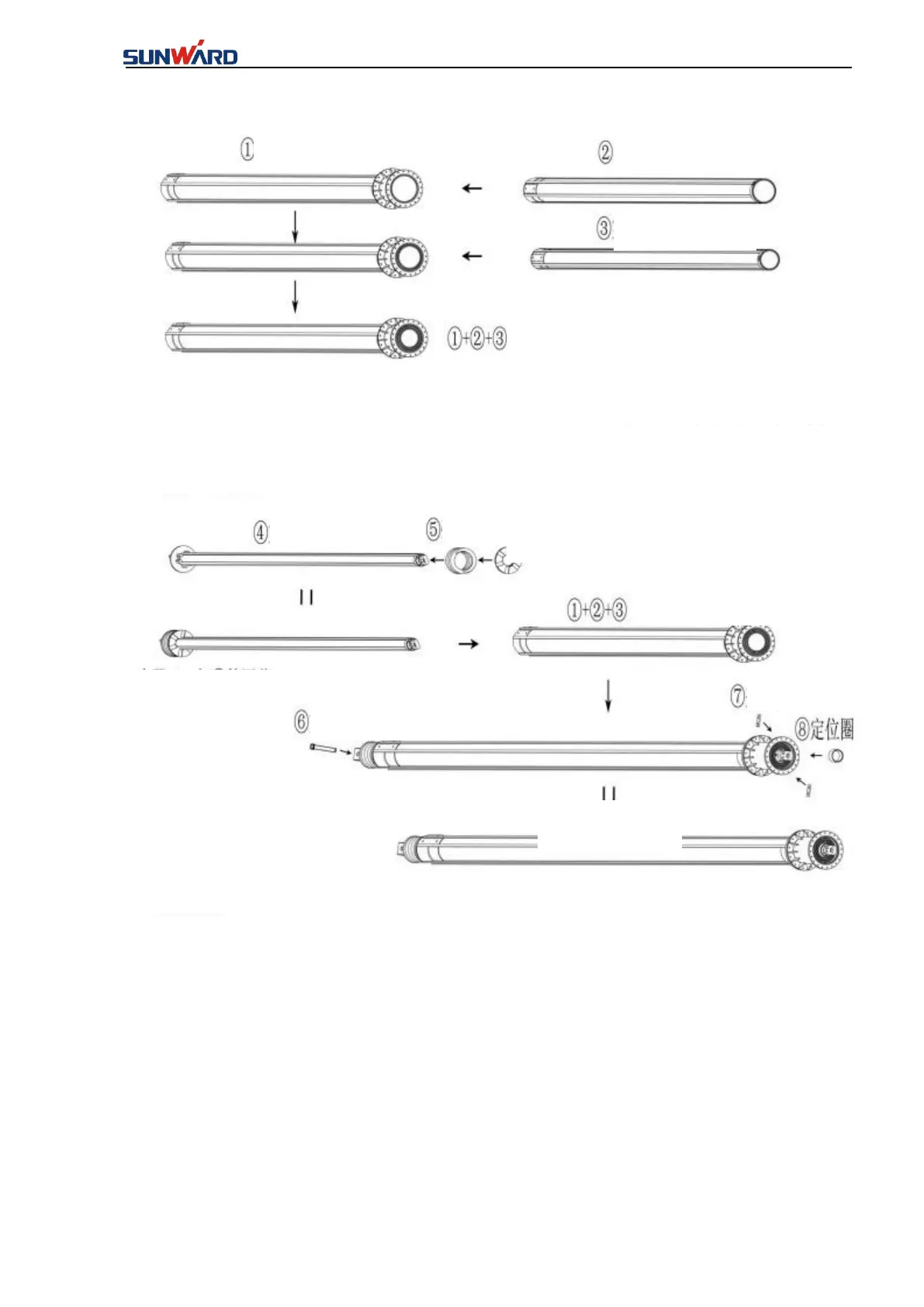

Step 2: Cushion the 4

th

section with

crosstie on the ground, pull the spring

and disc through the 4

th

section

successively.

Step 3: Assemble the

4

th

section through the

1

st

section, 2

nd

section

and 3

rd

section, then

install positioning

ring, clamp plate and

square head pin shaft

successively on the 4

th

section.

The winch should be used to assemble

Kelly.

Loading...

Loading...