SWDM40 OPERATION & MAINTENANCE MANUAL

4)Take walk-around inspection for the machine to check abrasion, damage and oil leakage,

especially for parts as below:

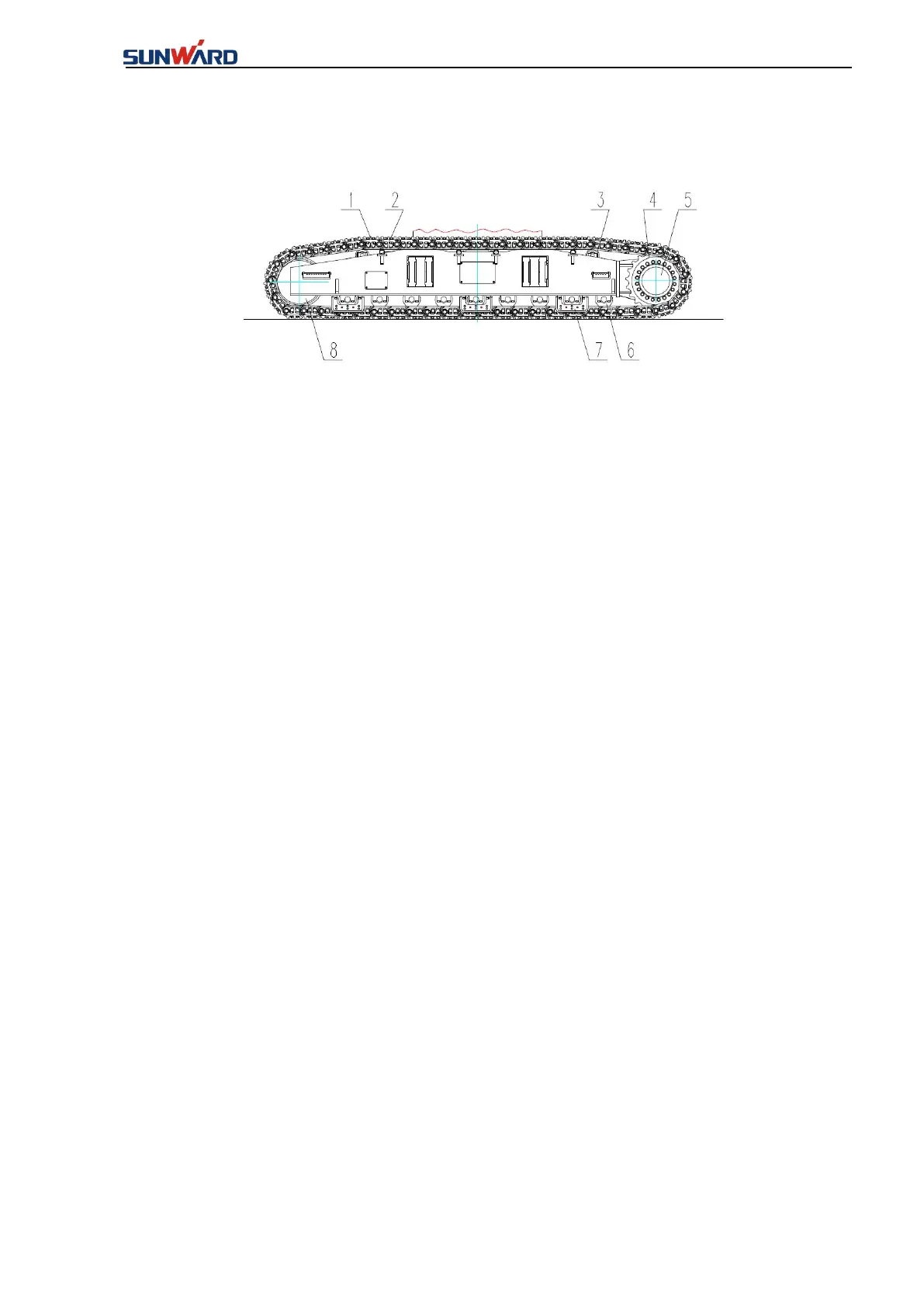

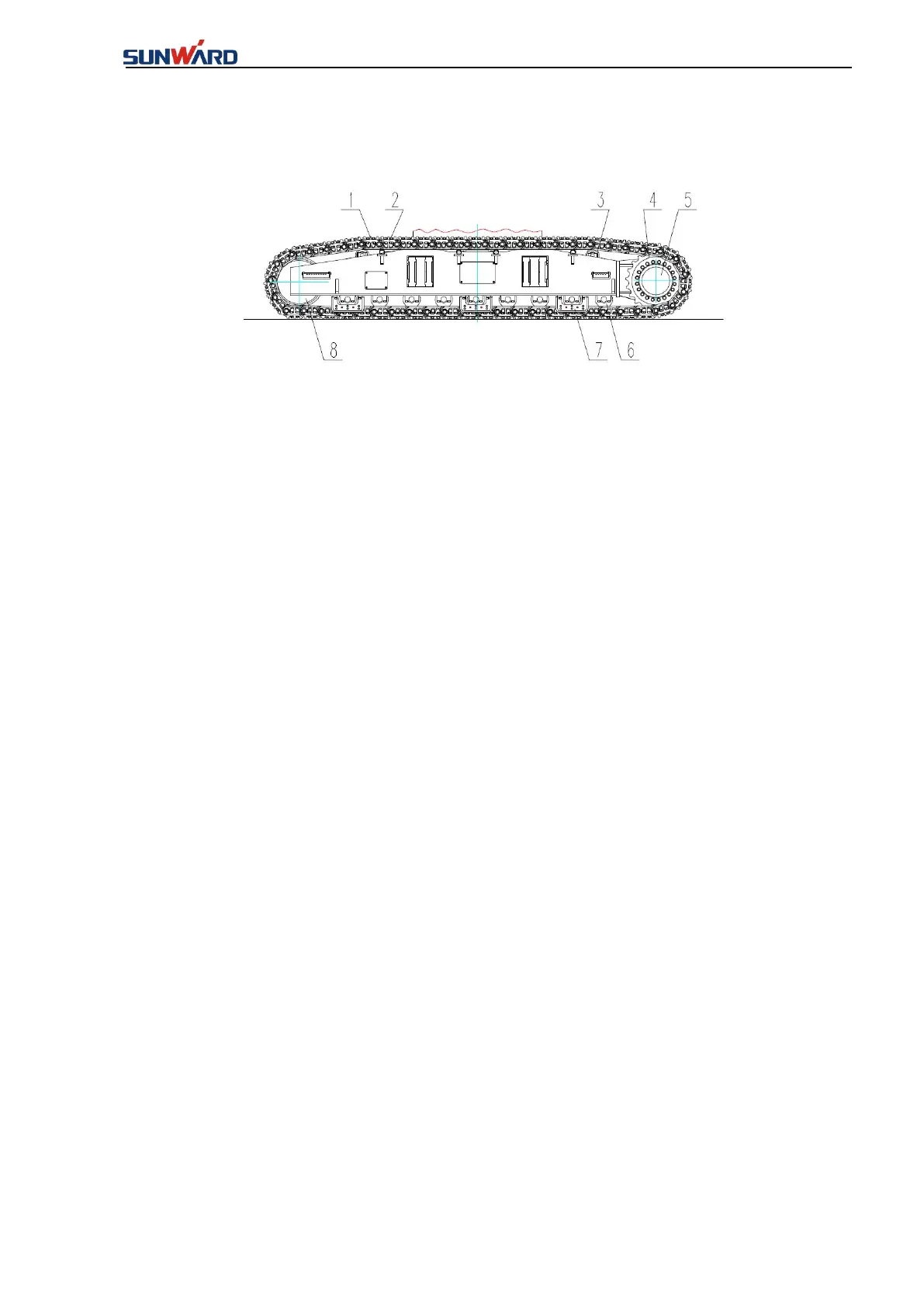

FIG. 8-3-6 Track Components

(1)Track shoe(2)Chain rail section(3)Carrier roller(4)Driver sprocket

(5)Reduction gearbox(6)Track roller(7)Rail-clamp bracket(8)Idler

8.3.6 Wire Rope Inspection

Note:

When handling the wire rope, it’s possible to be hurt by broken part, thus, gloves

should be put on as an protective measure.

Much attention should be paid for maintenance, inspection and installation. Be careful

not to be involved in or pinched.

Wire rope is a quick-wear and vital part of the drilling rig. Correct selection, reasonable

use and regular maintenance as required can extend the service life and avoid accidents.

The type of wire rope should be specified by SUNWARD when changing wire ropes for

the main winch and auxiliary winch, any problem caused by failure to comply, that SUNWARD

will not take any responsibility.

Regular inspection should include following aspects:

Requirements of laws and regulations of State.

Equipment work level.

Previous test results and problem.

Used time of wire rope.

Much attention should be paid to following parts:

Beginning and end for wire rope movable and fixed part

Strands on rope sheave

Rope sections may be abraded by some factors.

Check the location of wire rope for secure.

Check joint nearby for broken strand, crack and wire rope diameter.

Visual inspect the overall length of wire rope for damage and deformation. When

broken wire, abrasion, corrosion and deformation is found, determine whether it’s

Loading...

Loading...