SWDM40 OPERATION & MAINTENANCE MANUAL

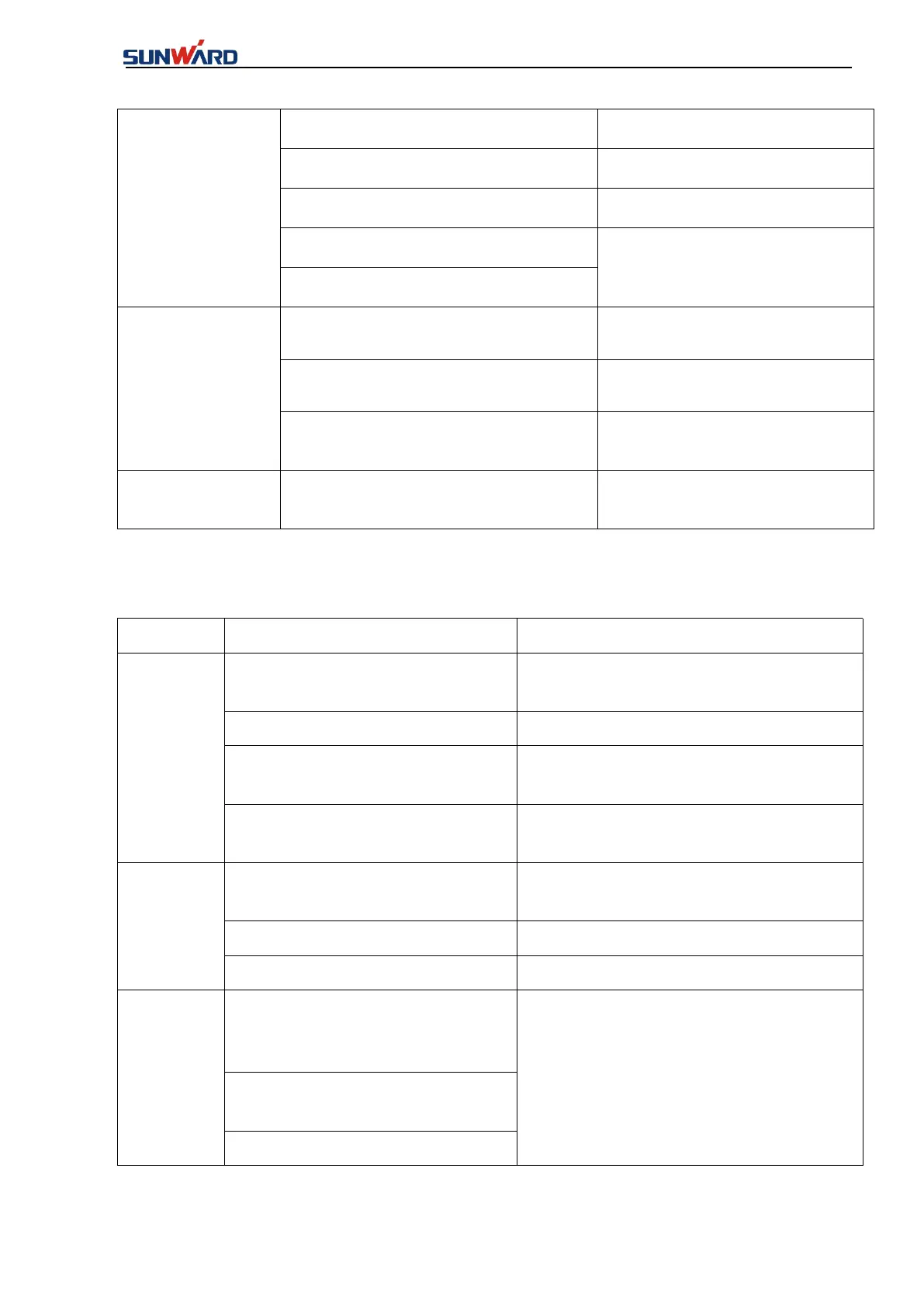

One side of crawlers

not moving/ moving

slowly

Changing valve and brake valve failure

Oil seal for center joint damaged

Travel reduction gearbox failure

Hydraulic oil

temperature too high

or advances too fast

Impurity in radiator surface

Hyd. Components worn out, low efficiency

Overflow valve on/off over frequent

Drill too fast in heavy load, reduces

drill speed

Abnormal sound,

vibration or smell

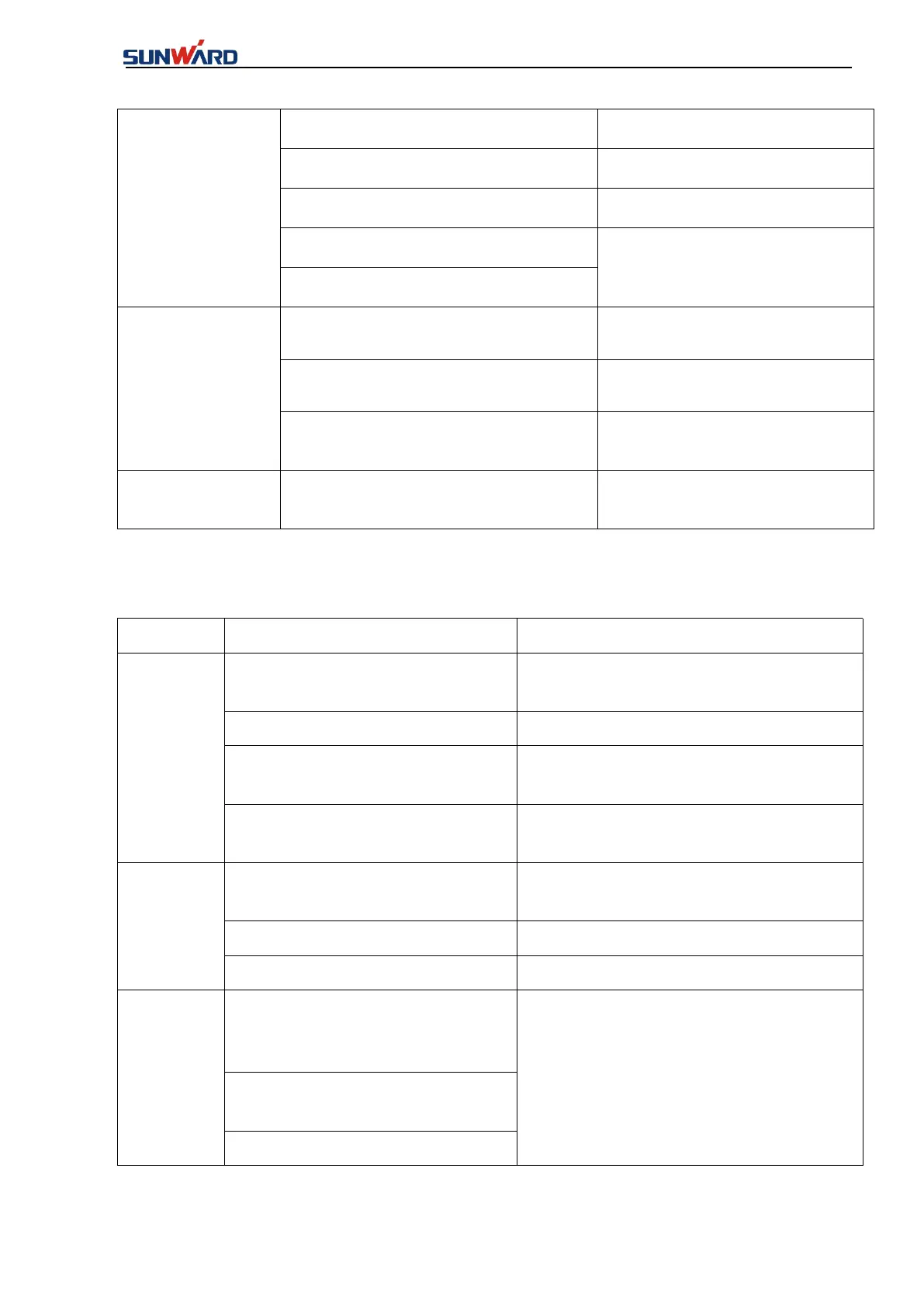

9.2 ACCIDENTS AND SOLUTIONS DURING DRILLING

Drilling tools collide with sleeves and

protective walls.

Careful management and construction.

Wrong hole boring method.

Choose an appropriate hole boring method.

Sleeves are not embedded into compact

soil.

Compact the soil around the sleeves

Slurry is not suit for soil condition.

Adjust the slurry properties according to

stratum condition.

The drilling rig is not leveled and Kelly

is not vertical.

Adjust level and vertical

Serious abrasion of driving sleeve.

Gentle press and slow drill

Drilling tools lifting and falling speed is

too fast and produce sucking pressure

and activation pressure.

On one hand, the geographical condition should

be known all –round to avoid accidents. On the

other hand, after the accident happens,

applicable measures shall be taken.

The deposit is very thick, the speed is

too fast so that the tools are stunk.

Loading...

Loading...