SWDM40 OPERATION & MAINTENANCE MANUAL

8.3.13 Checking Hydraulic Oil Level and Quality

Warning!

If hydraulic oil is hot, please don’t remove the filling plug, air outlet plug on the

hydraulic tank, failure to comply may result in the damage of oil pump caused by

air entering into the hydraulic system.

If air enter into the hydraulic system, it will damage the oil pump.

Hot oil and component may get people hurt, thus, please don’t allow that to touch

your skin.

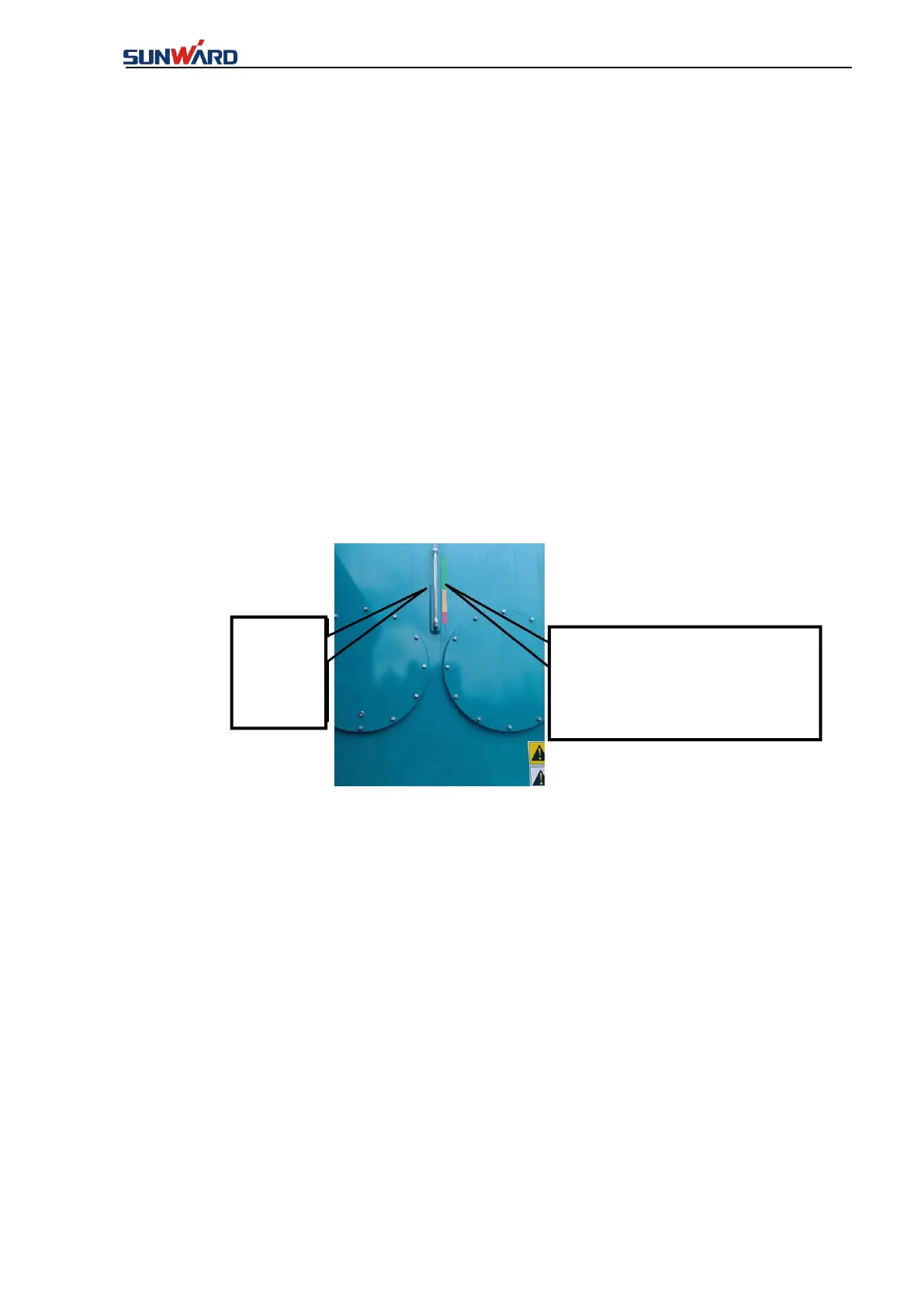

1. Park the machine on level ground, open the side door to visually inspect the hydraulic level

gauge and check hydraulic oil level and quality:

(1) The hydraulic oil level should not lower than the indicate line of red zone during operation;

(2)The hydraulic oil level should not lower than the indicate line of yellow zone during

transport;

(3) Visually check the hydraulic quality, if it turns to black or white, please change it at once.

FIG. 8-3-16

8.3.14 Checking Gear Oil Level for Reduction Gearbox

■ The machine should be shut down when checking gear oil level for reduction gearbox;

■ Any one of following methods can be used:

(1)Visual inspection for reduction gearbox sight glass, the oil level should be above 1/2 of the

sight glass;

(2)Take out gear oil dipstick to measure oil level, which approaches to the highest scale;

(3)Screw off the inspection hole plug to check oil level, and gear oil flows out.

■ The machine should be parked on level ground to check gear oil for main winch reduction

gearbox; Erect the drill mast vertical to check gear oil level for Rotary drive reduction gearbox

and crowd winch reduction gearbox.

■ Inspection after running, the machine should be shut down for over than 30 minutes to cool

down. If plug should be screwed off or the level dipstick should be taken out, wear protective

gloves when checking oil level, beside, unscrew the plug slowly to release inner pressure in the

Hydraulic Oil Level Warning Label

Green: safe oil level

Yellow: warning oil level

Red: dangerous oil level

Level

gauge of

hydraulic

tank

Loading...

Loading...