SWDM40 OPERATION & MAINTENANCE MANUAL

8.3.3 Checking Oil Level in Rotary drive Gearbox

Note:

If the color of gear oil has changed, indicating that water has mixed into oil, change

gear oil immediately. Drain up the used oil before refilling and wash the reduction

gearbox with new oil for times.

1. Keep liquid level on proper position.

2. Check oil level when Rotary drive is still.

3. The oil level should be at the 1/2-2/3 position of view glass.

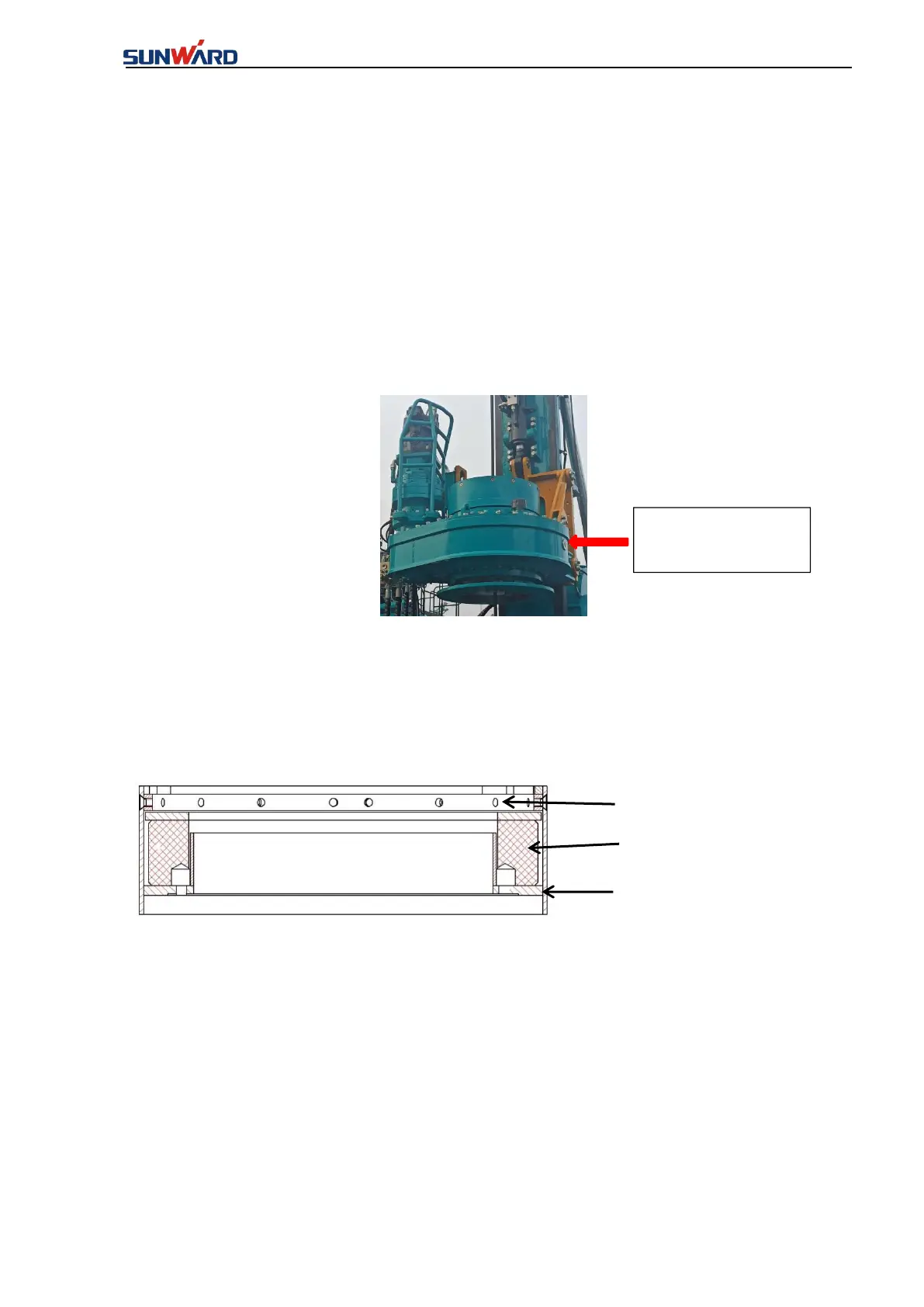

FIG. 8-3-4 Check oil level for reduction gearbox

8.3.4 Checking cushion device of Rotary drive

Check cushion device of Rotary drive and key bar every day, figure out the abrasion condition

of the machine; especially, after smashing the rod, inspection is necessary, and replace related

parts.

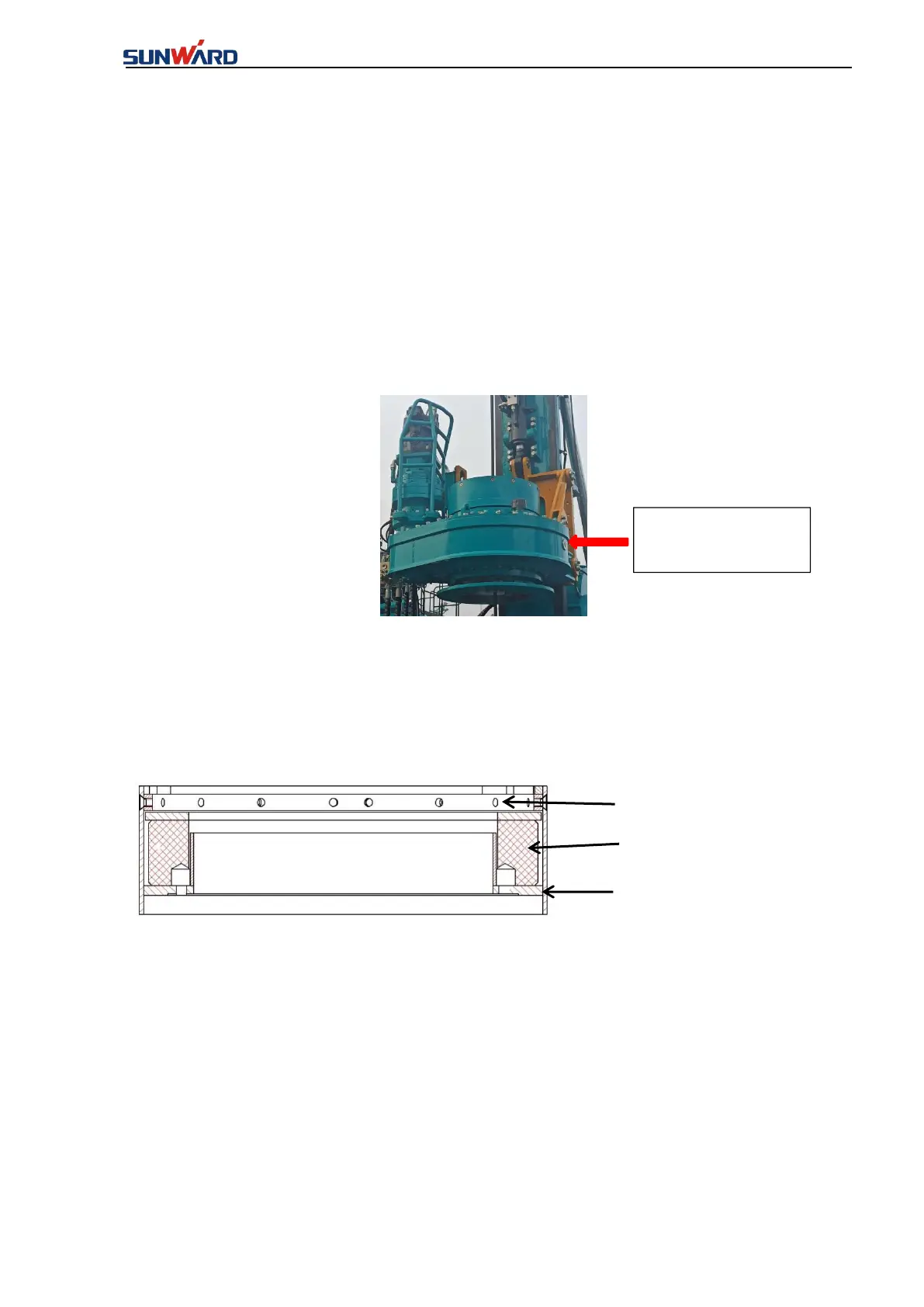

FIG. 8-3-5 Cushion device

1)Check rotating disk for abrasion, deformation or damage, replace it if necessary.

2)Check spring for deformation or damage, replace it if necessary.

3)Check thread on spring guide pin, especial after smashing rod, if transformed or damaged,

repair or change cushion seat.

8.3.5 Check Track Components for Lost or Damaged

1)Keep upper-carriage vertical with the track and clean mud on the track completely.

2)Check joint bolts for drive sprocket, reduction gearbox, track shoe and chain rail.

3)After extending the track, apply grease onto the telescopic beam of the track to avoid rust.

Loading...

Loading...