SWDM40 OPERATION & MAINTENANCE MANUAL

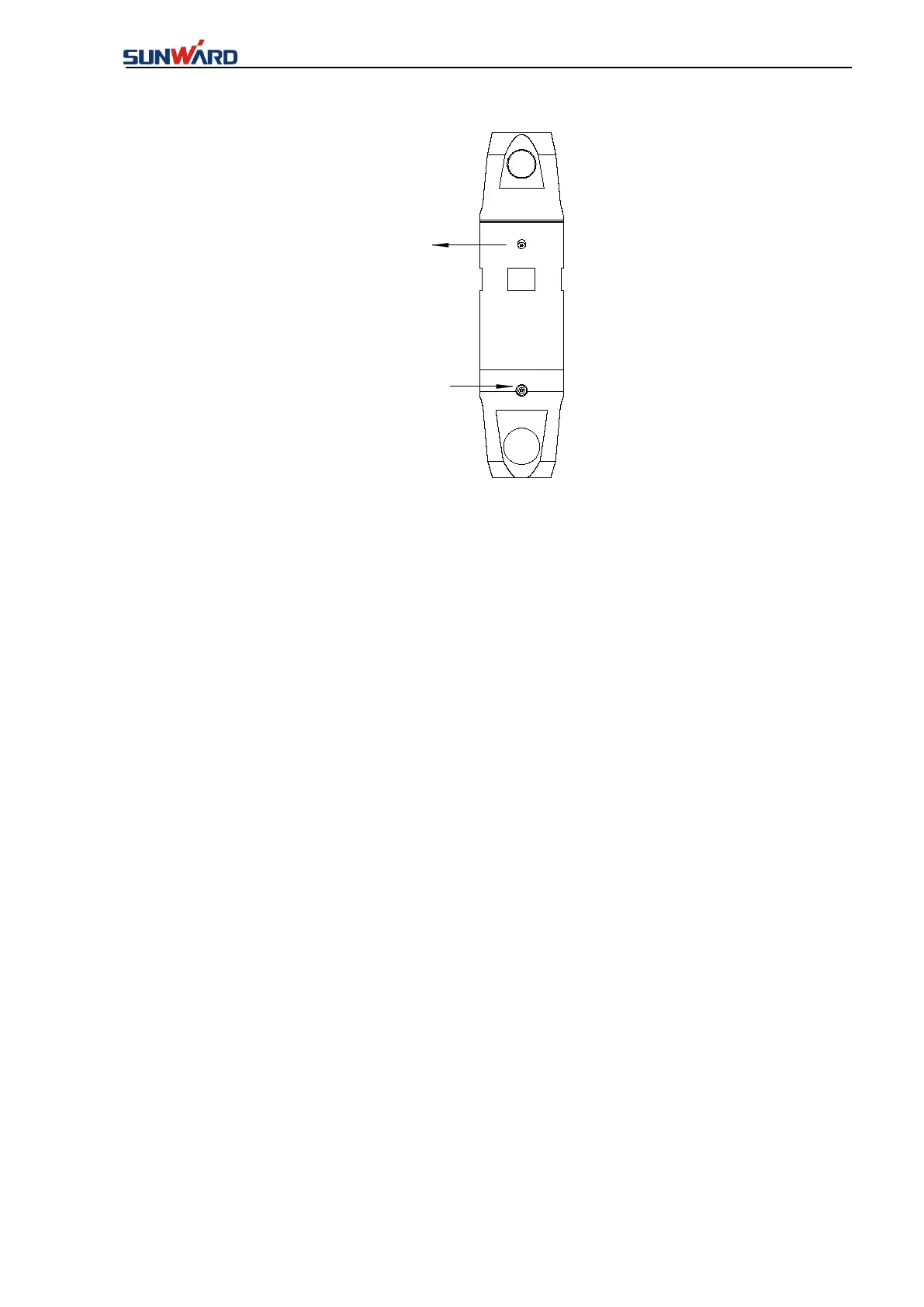

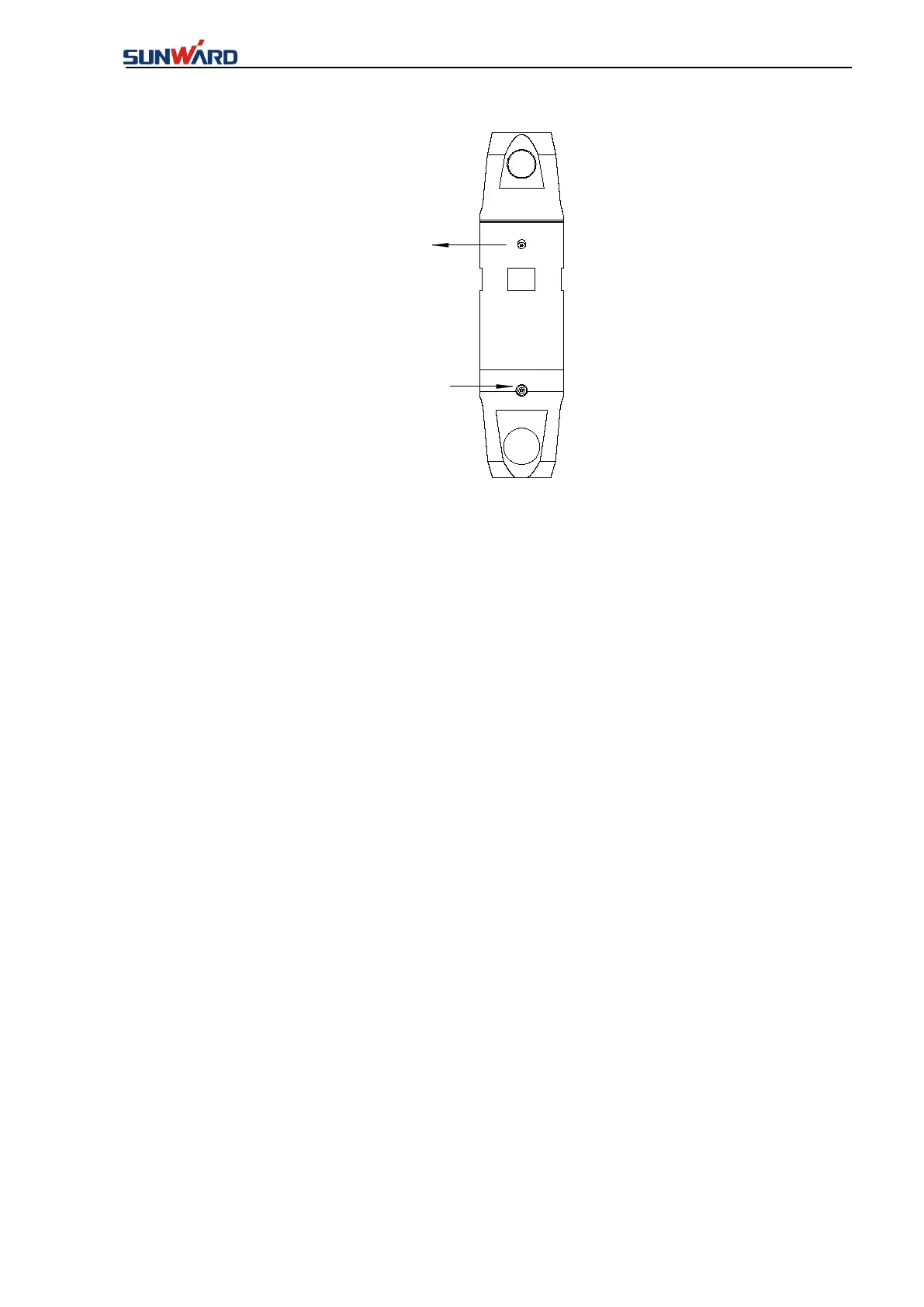

FIG. 8-3-10 Swivel Joint Structure

Special note: The plug M10X1 on the other side should be unscrewed when injecting grease

into the grease cup from one end of the swivel joint. In this way, the used lubricating grease can

be squeezed out. Failure to comply may damage the oil seal of the swivel joint, mix impurity

into grease, such as fine sediment, and lead to the reduction in flexibility, using performance

and stability of the swivel joint.

2)If swivel joint is still difficult to rotate after lubrication, repair or change it.

3)Replace parts or swivel joint with original specification for safety.

Lubrication requirements:

1)Apply lubricating grease once every day. Use #2 lithium base lubricating grease in summer

and #1 lithium base lubricating grease in winter.

2)Check swivel joint for secure when applying lubricating grease at every time, if loosened,

fasten in time.

3)Check upper and lower pin shafts which link with the swivel joint when applying lubricating

grease at every time, if loosened, fasten in time.

4)After applying lubricating grease, rotate the upper end of the swivel joint when there’s no

load, if it can’t swing or is blocked, repair or change at once.

5)When working on the area with the temperature under 0℃, clean swivel joint in time, wipe

with clean cloth and apply anti-freeze grease on the junction surface to avoid rotary junction

surface freezing on the ground. Before next shift, turn the upper end of swivel joint with hands

to check for freeze. If frozen, thaw with hot water and wipe out, and then check the flexibility

before operation.

Loading...

Loading...