3-36 ENGINE

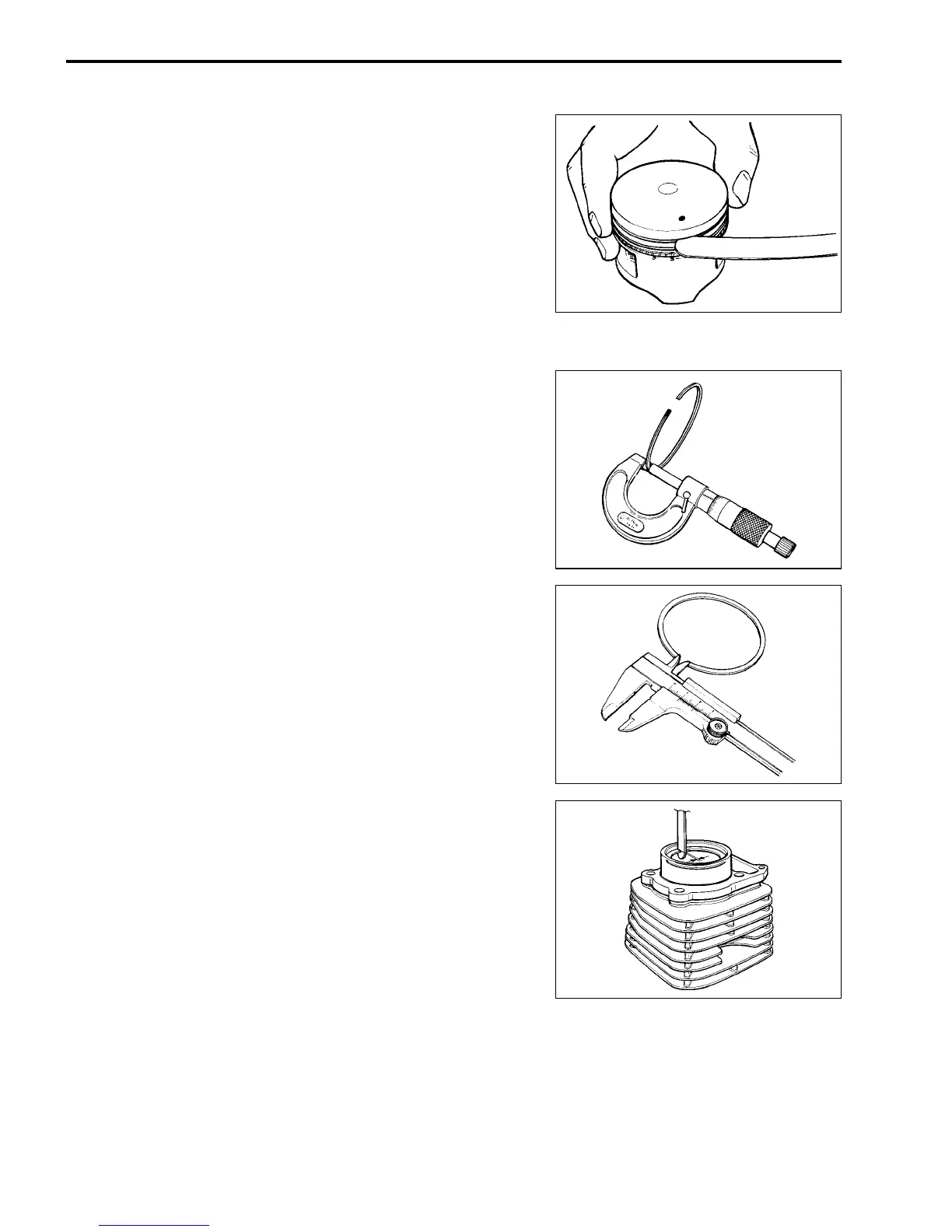

PISTON RING TO GROOVE CLEARANCE

Using a thickness gauge, measure the side clearances of the

1st and 2nd rings. If any of the clearances exceeds the limit,

replace both piston and piston rings.

Piston ring to groove clearance

Service Limit (1st) : 0.18 mm (0.0071 in)

(2nd): 0.15 mm (0.0059 in)

Piston ring groove width

Standard (1st) : 1.01 – 1.03 mm (0.0398 – 0.0406 in)

(2nd): 1.21 – 1.23 mm (0.0476 – 0.0484 in)

(Oil) : 2.01 – 2.03 mm (0.0791 – 0.0799 in)

Piston ring thickness

Standard (1st) : 0.97 – 0.99 mm

(0.038 – 0.039 in)

(2nd): 1.17 – 1.19 mm

(0.046 – 0.047 in)

09900-20803: Thickness gauge

09900-20205: Micrometer (0 – 25 mm)

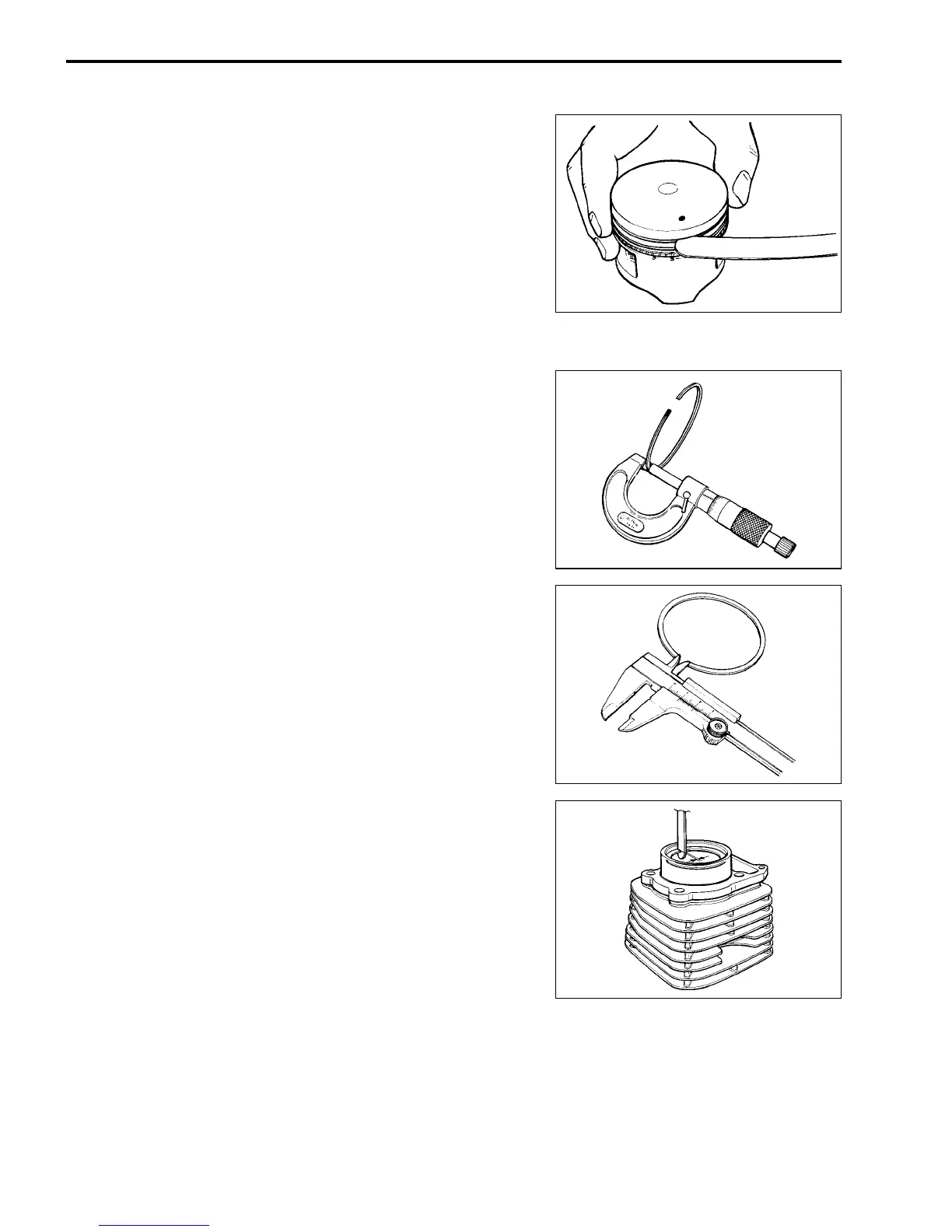

PISTON RING FREE END GAP AND END GAP

Before installing piston rings, measure the free end gap of each

ring using vernier calipers. Next, fit the ring in the cylinder, and

measure each ring end gap using a thickness gauge.

If any ring has an excess end gap, replace the ring.

Piston ring free end gap

Service Limit (1st) : 7.0 mm (0.28 in)

(2nd): 7.2 mm (0.28 in)

Piston ring end gap

Service Limit (1st) : 0.50 mm (0.020 in)

(2nd): 0.50 mm (0.020 in)

09900-20101: Vernier calipers

09900-20803: Thickness gauge

Loading...

Loading...