TOMARK, s.r.o.

Airplane Maintenance Manual

Chapter 05 Inspection and Maintenance

Page 34 Issue: 04.APR 2016

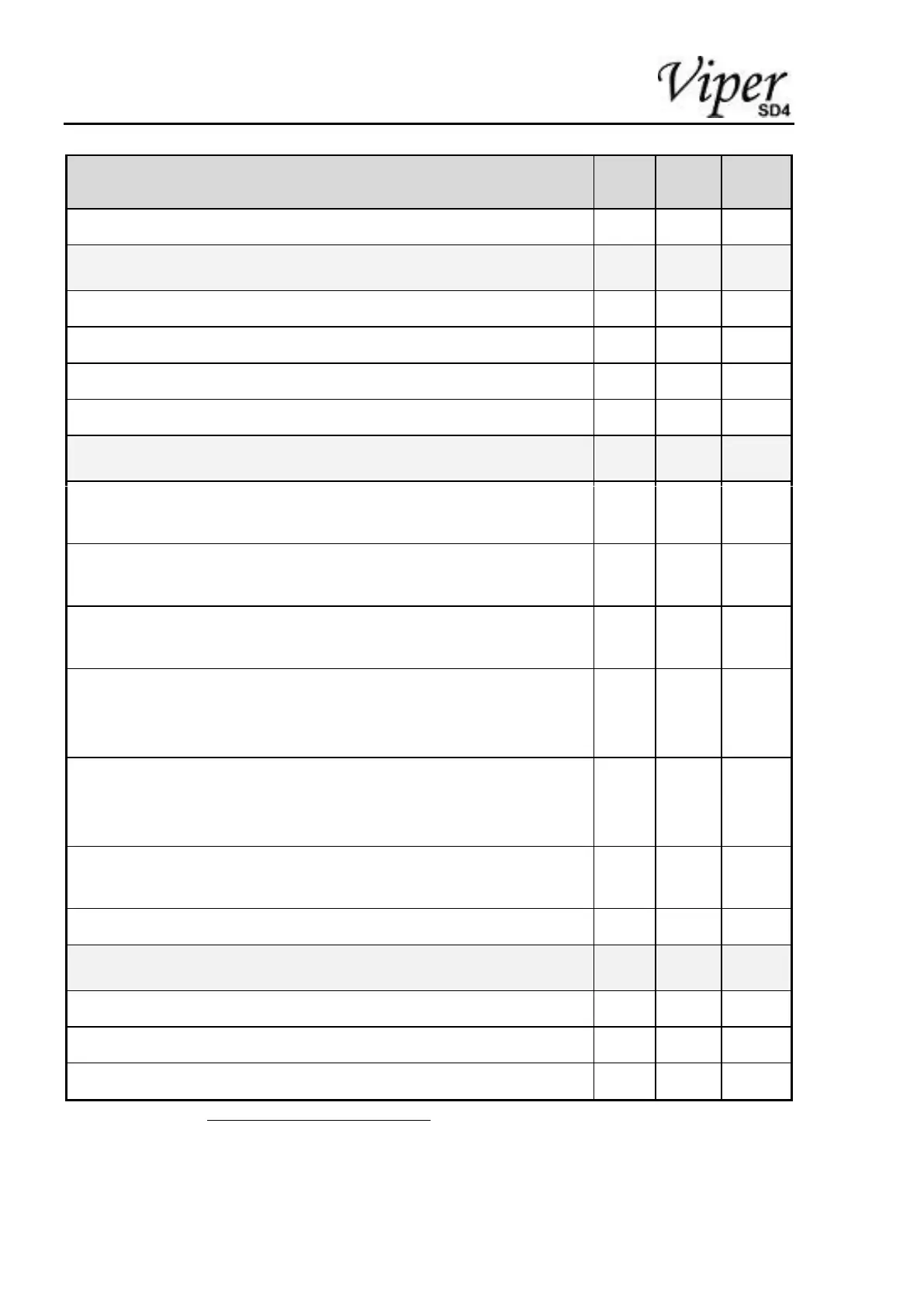

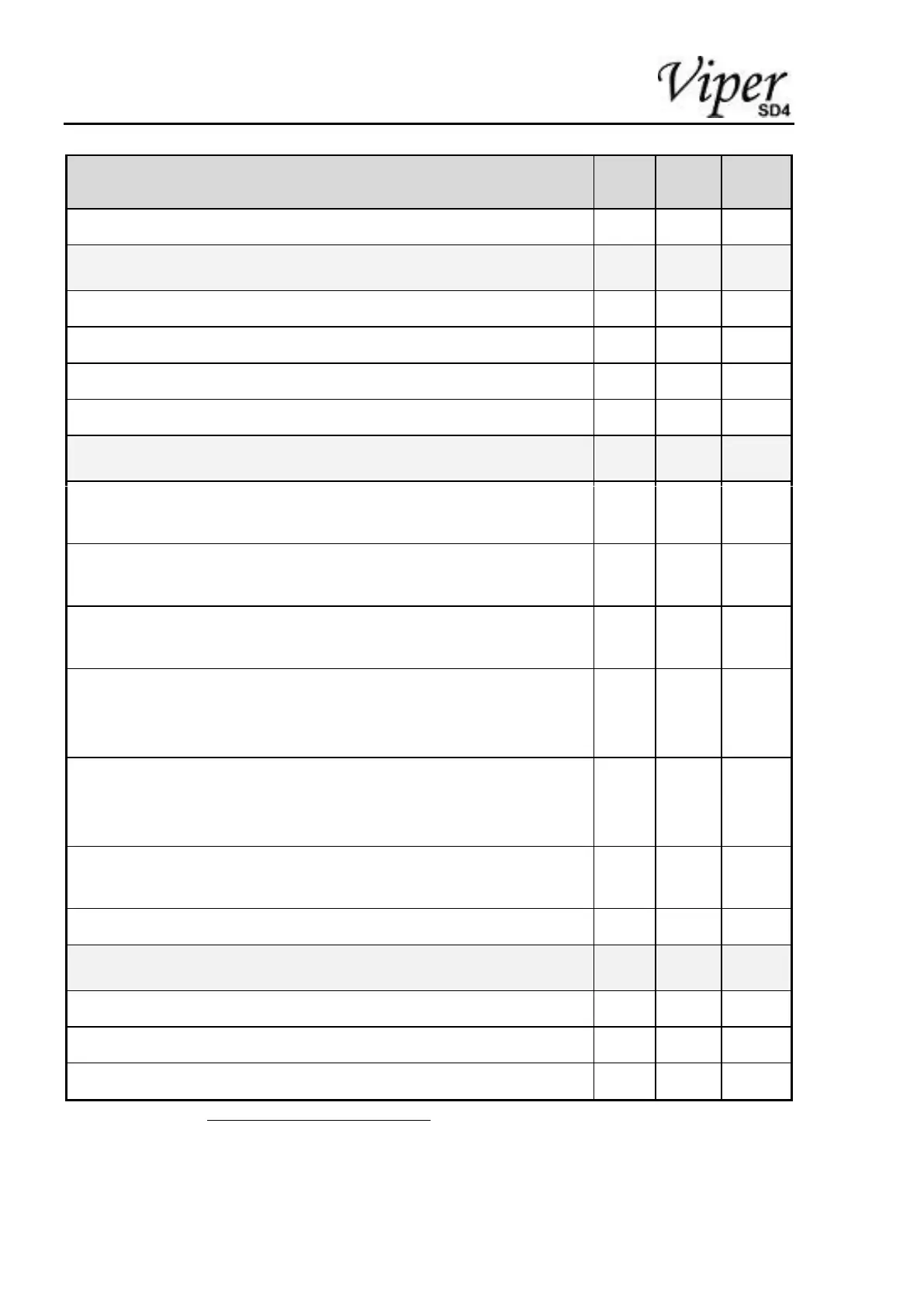

Inspect battery isolation provisions.

Inspect hoses for attachment, leaks and wear.

Inspect air scoop at radiator for cleanness

Inspect save closure of cabin air nozzles and vents

Inspect heat exchanger on exhaust for cracks

Inspect engine mount attaching bolts at the firewall. Check

torque on all attachment points, re-torque as required.

Inspect shock mount rubber elements (vibration isolators) for

condition.

Check engine to shock mount attaching bolts, castle nuts and

cotter pins.

Inspect engine mount structure for cracks and damage.

Pay specific attention to weld connections. In case of doubt

consider dye penetrant inspection.

Visually check the firewall for cracks and corrosion, in

particular in the places of all the engine mount attachment

points.

Unscrew and visually check the condition of the bolts

attaching the engine to the engine mount.

Perform Major engine mount inspection per

04-30-20.

Inspect spinner for cracks and fractures.

Inspect propeller mounting bolts. Re-torque mounting bolts.

First 25 hours of operation for new or overhauled engine

Loading...

Loading...