25

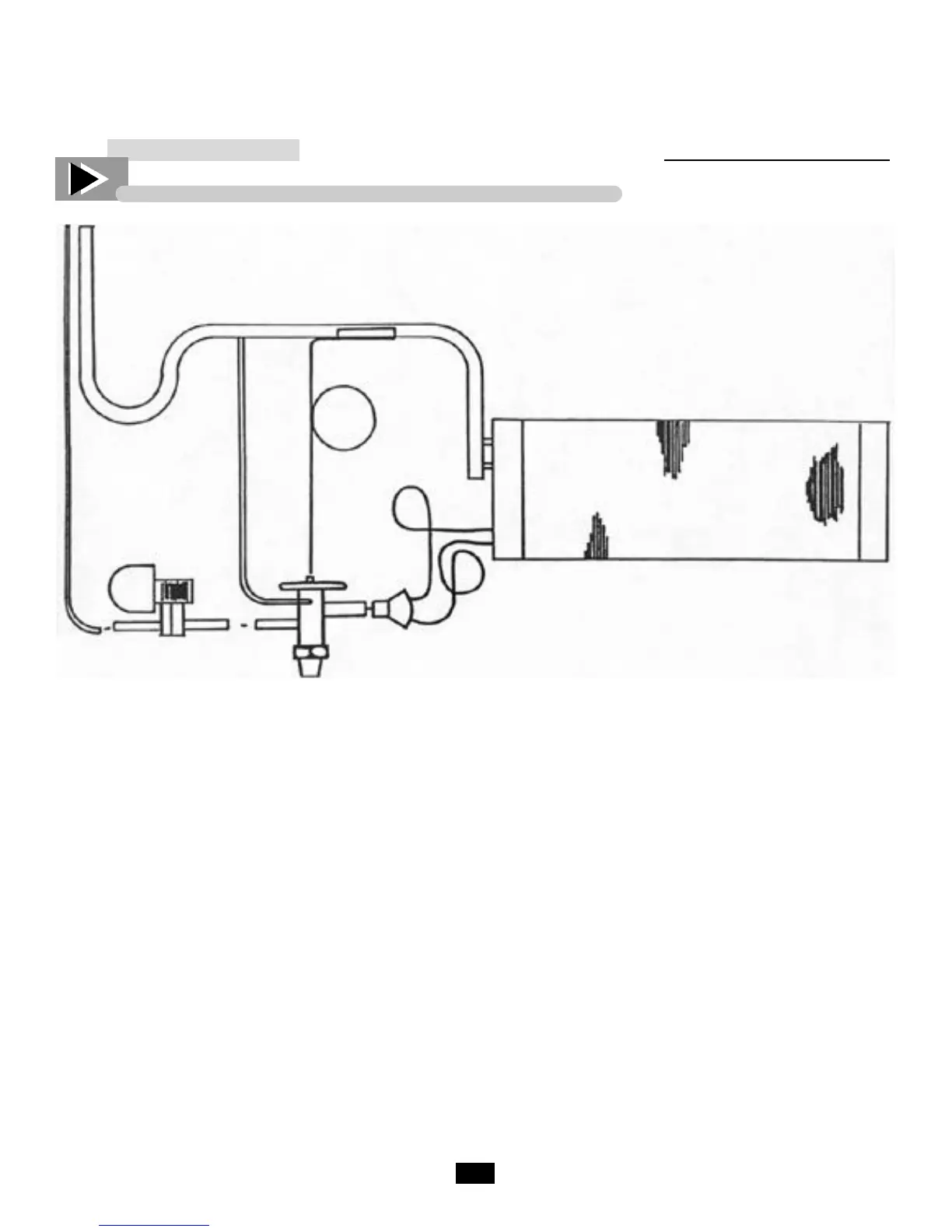

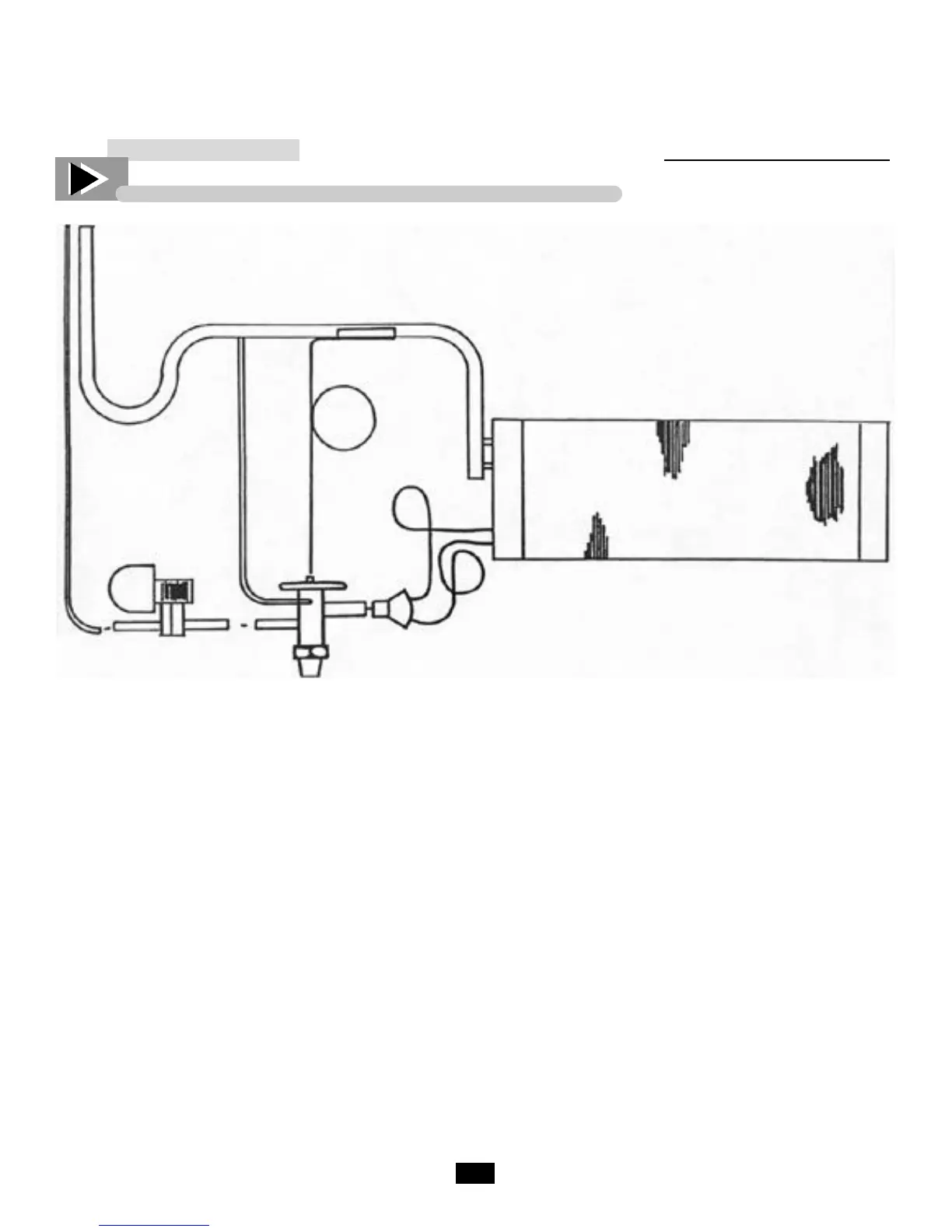

TRUE’S REMOTE SYSTEM - HOW IT WORKS

Refrigeration Schematic Diagram

Suction Line

TXV Bulb

Evaporator

Coil

Feeder

Tubes

Distributor

with Nozzle

Liquid Line

Solenoid

External

Equalizer

‘P’ Trap

Liquid and Suction

Tubing

TXV

The suction line will exit the evaporator coil as usual

for self-contained models, except it shall include an

Oil “P” trap. This is used to trap oil in low velocity

suction gases at a point just prior to a vertical rise.

Whether the compressor is to be located above or

below the evaporator, (True does not have control

over this), the suction will always have a “P” trap in

case the compressor is installed overhead.

The liquid line shall enter the cabinet and go direct-

ly to the liquid line solenoid, this is a normally

closed refrigerant valve which will be energized and

wired in series with the thermostat. When the ther-

mostat is closed (requires refrigeration) the solenoid

will be energized to open, allowing refrigerant to

pass to the “thermal expansion valve” (TXV). The

TXV allows refrigerant through to the evaporator

coil. If the evaporator has more than one circuit, a

distributor is used which evenly distributes refriger-

ant to each circuit. The TXV is made to open and

close by its sensing bulb which senses suction line

temperature on the other side of the evaporator. The

sensing bulb has the same refrigerant that is used in

the refrigeration system. When hot air passes over

the evaporator coil and warms the refrigerant, the

sensing bulb senses the warm condition and pushes

the sensing valve open. When too much refrigerant

flows into the evaporator, the sensing bulbs refriger-

ant cools and contracts allowing the diaphragm to

ease away the needle valve, thus closing the valve.

The external equalizer is another sensing element

which helps the sensing bulb to more accurately feed

refrigerant. The external equalizer line must be

down-stream of the TXV bulb. The TXV bulb

should be insulated with corktape.

Loading...

Loading...