54 | CFW700

Troubleshooting and Maintenance

English

ATTENTION!

The electronic cards have components sensitive to electrostatic discharges.

Do not touch directly on the components or connectors. If necessary, first touch

the grounded metallic frame or use proper grounding strap.

Do not execute any applied potential test on the inverter!

If necessary, contact WEG.

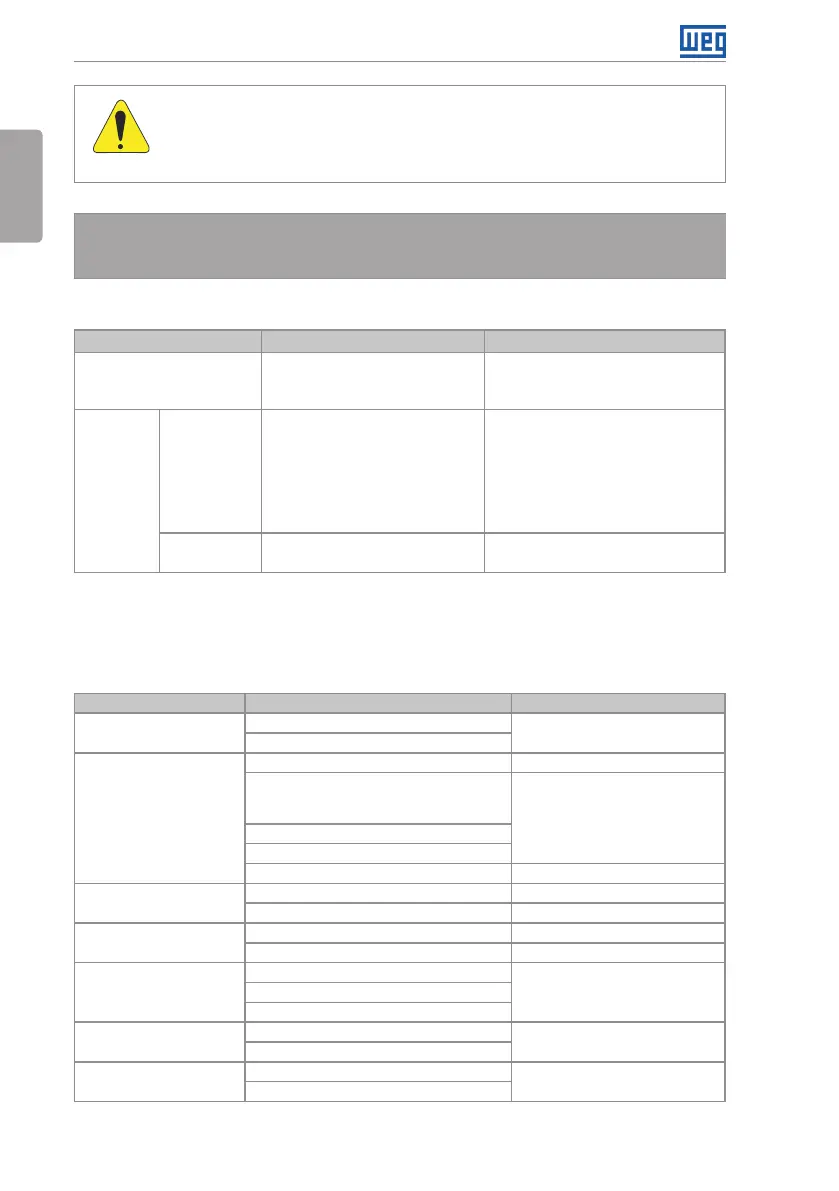

Table 6.2: Preventive maintenance

Maintenance Interval Instructions

Fan replacement After 50.000 hours of operation.

(1)

Replacement procedure shown in

Figure 6.1 on page 55 and Figure

6.2 on page 56.

Electrolytic

capacitors

If the inverter

is stocked

(not in use):

“Reforming”

Every year from the

manufacturing date printed on

the inverter identification label

(refer to chapter 2 GENERAL

INSTRUCTIONS on page 3).

Apply power to the inverter with

voltage between 220 and 230 Vac,

single-phase or three-phase, 50 or

60 Hz, for at least one hour. Then,

disconnect the power supply and

wait for at least 24 hours before

using the inverter (reapply power).

Inverter being

used: replace

Every 10 years.

Contact WEG technical support to

obtain replacement procedure.

(1) The inverters are set at the factory for automatic control of the fans (P0352 = 2), so that they are only started when

the temperature of the heatsink increases. Therefore number of operating hours of the fans will depend on the operating

conditions (motor current, output frequency, temperature of the refrigeration air, etc.). The inverted records in P0045 the

number of hours the fan remained ON. When the fan reaches 50,000 hours of operation, the HMI display will show the

ala r m A177.

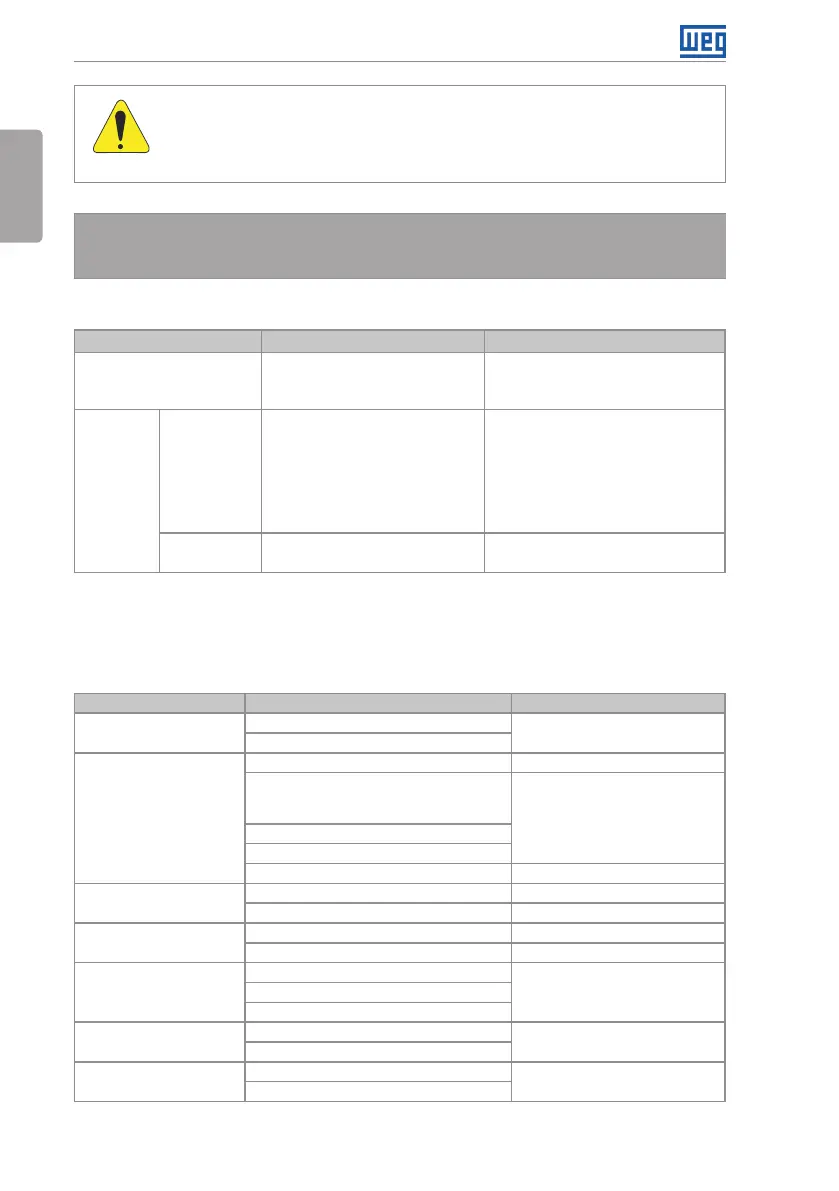

Table 6.3: Periodic inspection at every 6 months

Component Abnormality Corrective Action

Terminals, connectors

Loose screws

Tighten

Loose connectors

Fans /Cooling systems

Dirty fans Cleaning

Abnormal acoustic noise

Replace fan. See Figure 6.1

on page 55 and Figure 6.2

on page 56. Check fan

connections.

Blocked fan

Abnormal vibration

Dust in the panel air filters Cleaning or replacement

Printed circuit boards

Accumulation of dust, oil, humidity, etc. Cleaning

Odor Replacement

Power module/ Power

connections

Accumulation of dust, oil, humidity, etc. Cleaning

Loose connection screws Tightening

Capacitors of the DC

link (Intermediate Circuit)

Discoloration/ odor / electrolyte leakage

ReplacementSafety valve expanded or broken

Frame expansion

Power resistors

Discoloration

Replacement

Odor

Heatsink

Accumulation of dust

Cleaning

Dirt

Loading...

Loading...