CHAPTER 7 - PROGRAMMING INFORMATION AND SUGGESTIONS

150

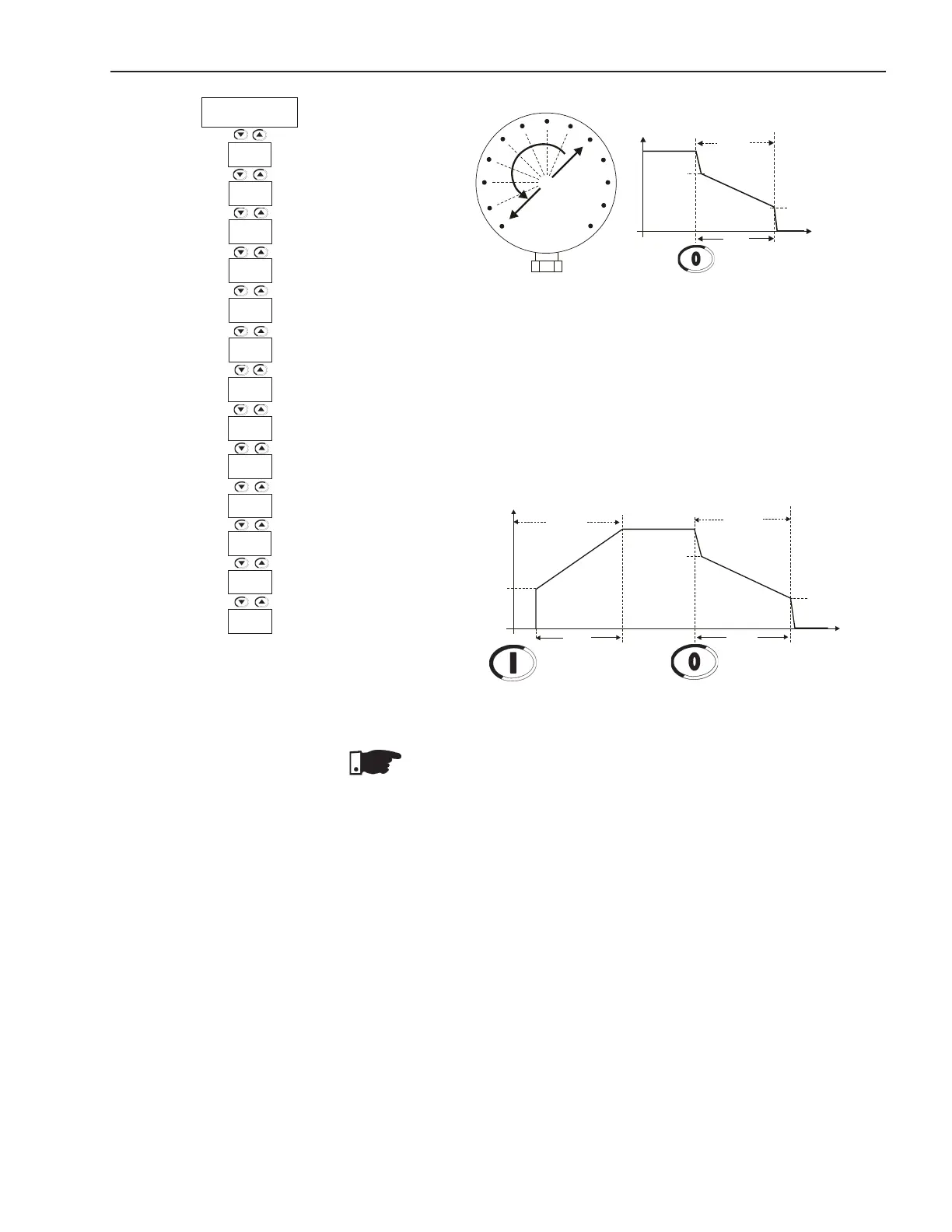

Figure 7.9 - Manometer showing the pressure drop

9) Generally, the current increases at the end of the deceleration

ramp and in this case the motor requires more torque to achieve

asmoothwaterowstop.Whenthemotorhasalreadystopped,

but is still enabled, the current will increase too much. To prevent

this condition, set P105 to a value that as soon it stop it is also

disabled;

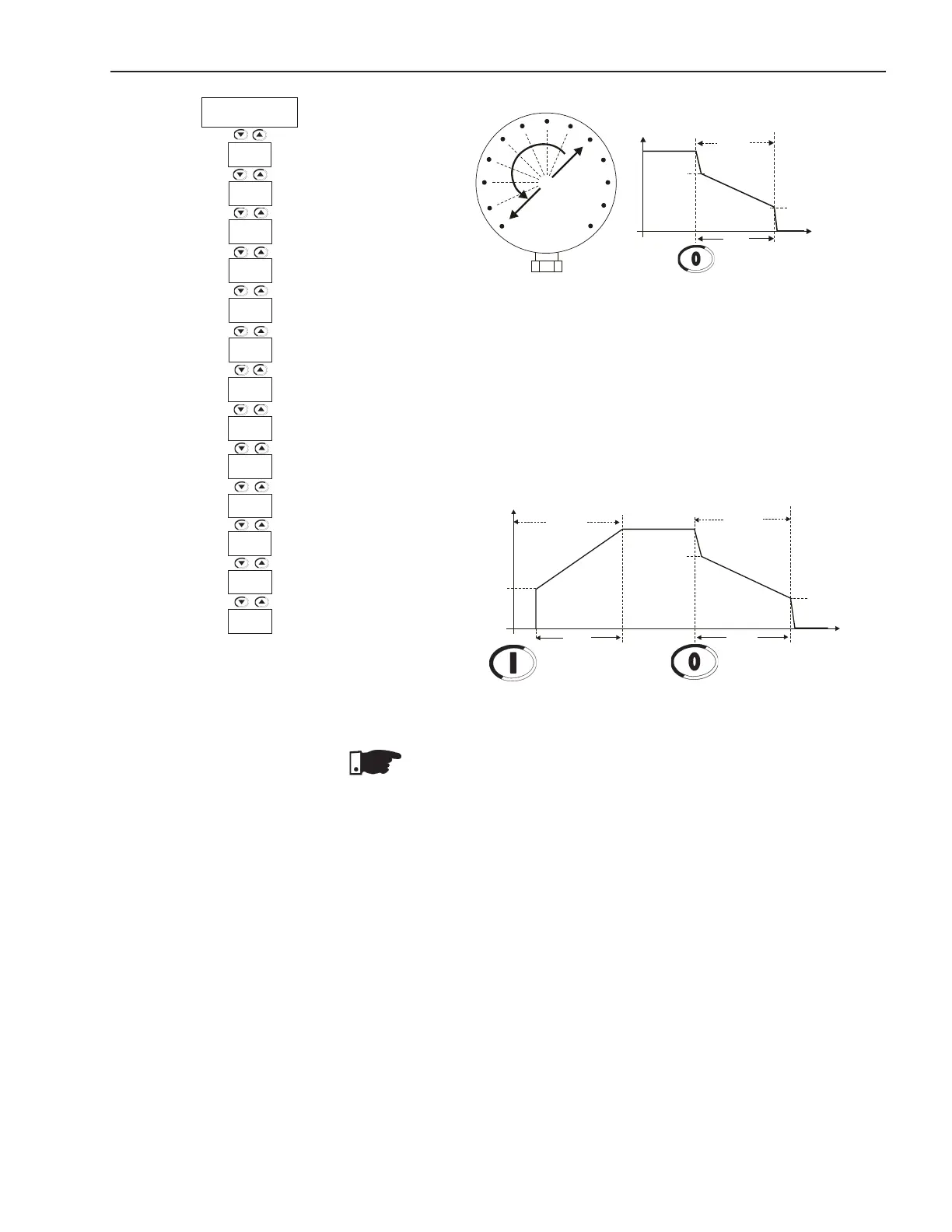

10) Set P610 and P611 to current and time levels that prevent the

hydraulic pump from running without a load.

NOTES!

1) P400 and P401 must be set according to the line voltage and the

nominal current of the used motor;

2) Ifthehydraulicpipingisnotttedwithamanometer,thewater

hammer can be noted at the pressure relief valves;

3) Please consider, that sudden line voltage drops results in motor

torque drops. Thus, ensure that the power supply line characte-

ristics are within the characteristics required for motor operation;

4) If errors are detected during the motor start, check all connections

of the Soft-Starter to the power line, the motor connections, the

voltage levels of the power line, the fuses, circuit-breakers and

disconnecting switches.

Figure 7.10 - Start with pump control

U(V)

Start

Stop

P101

P102

0

Enable

Disable

t(s)

100%Un

Pump Control

P103

P104

P105

Disable

P104

t(s)

0

P103

U(V)

Stop

100%Un

P105

P611

P610

P401

P400

Pump

Control

P105

P104

P103

P102

P101

P130

P640

P406

P620

Loading...

Loading...