CHAPTER 8 - DIAGNOSTICS AND TROUBLESHOOTING

169

8.2 TROUBLESHOOTING

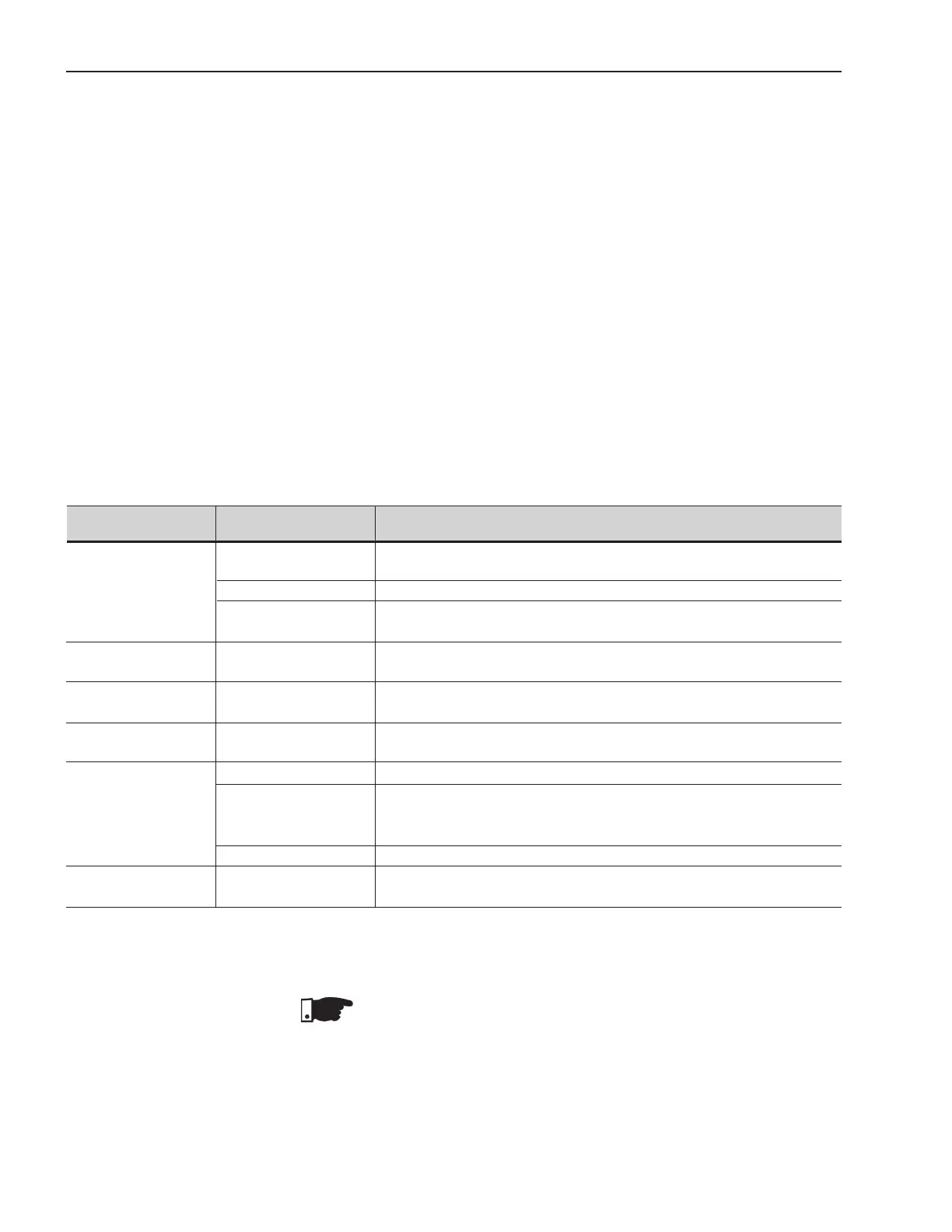

PROBLEM POINTTOBE CORRECTIVEACTION

CHECKED

Motor does not run Incorrect wiring 1. Check the power and control connections. For example the DIx digital inputs

programmed for Enabling or External Fault must be connected to +24V.

Incorrect programming 1. Check if the parameters are properly programmed for the application.

Fault 1. Check if the Soft-Starter is not disabled due to a Fault condition

(Refer to table 8.1).

Motor does not reach Motor stall 1. Increase the current limit level, if programmed to current limit.

nominal speed 2. Increase the torque limit level, if the torque control mode has been selected.

Motorspeedvaries Looseconnections 1. Disable Soft-Starter, switch OFF the power supply and tighten all connections.

(oscillates) 2. Check if all internal connections are tightened.

Motor speed too low Motor nameplate data 1. Check if the used motor meets the application requirements.

or too high

Display OFF Keypad connection 1. Check the keypad connections to the Soft-Starter.

Check the supply voltage 1. Nominal supply voltage must be following:

of the control board U

min

= 93.5 Vac

(X1.1, X1.2 and PE) U

max

= 253 Vac

Blown fuse 1. Replace the fuse of the control board.

Jerking during Parameter setting 1. Reduce the time set at P104.

pump deceleration of the Soft-Starter

Table 8.2 - Troubleshooting of the most frequent problems

NOTE!

When contacting WEG for service or technical assistance, please

have the following data on hand:

- Soft-Starter Model;

- Serial number, manufacturing date and hardware revision, as indi-

cated on the Soft-Starter nameplate (Refer to Section 2.4);

- Software Version (Refer to Section 2.2);

- Information about the application and Soft-Starter programming.

8.3 TECHNICAL

ASSISTANCE

CONTACTING

Alarm tripping form:

-ItindicatesthecodeontheLEDdisplayandthealarmdescription

ontheLCDdisplay;

- It is only an indication. The motor is not stopped;

- The relay that is programmed for “No Alarm” will be deactivated;

- The relay that is programmed for “Alarm” will be activated;

- They are automatically reset when the alarm situation disappears.

OTHER FAULTS:

-Relayisswitchedowhenprogrammedto"NoError";

- Relay is switched on when programmed to "With Error";

-Motorisswitchedo,whenitisenabled;

-IndicatesthefaultcodeintheLEDdisplay;

-TheLCDdisplayindicatesthefaultcodeandthefaultdescription;

- Some data is also saved in the EEPROM memory:

. Thenumberoftheoccurredfault(thevepreviousfaultsare

displaced);

. The status of the thermal protection (motor overload);

. The time of the running/powered hours.

Loading...

Loading...