CHAPTER 7 - PROGRAMMING INFORMATION AND SUGGESTIONS

153

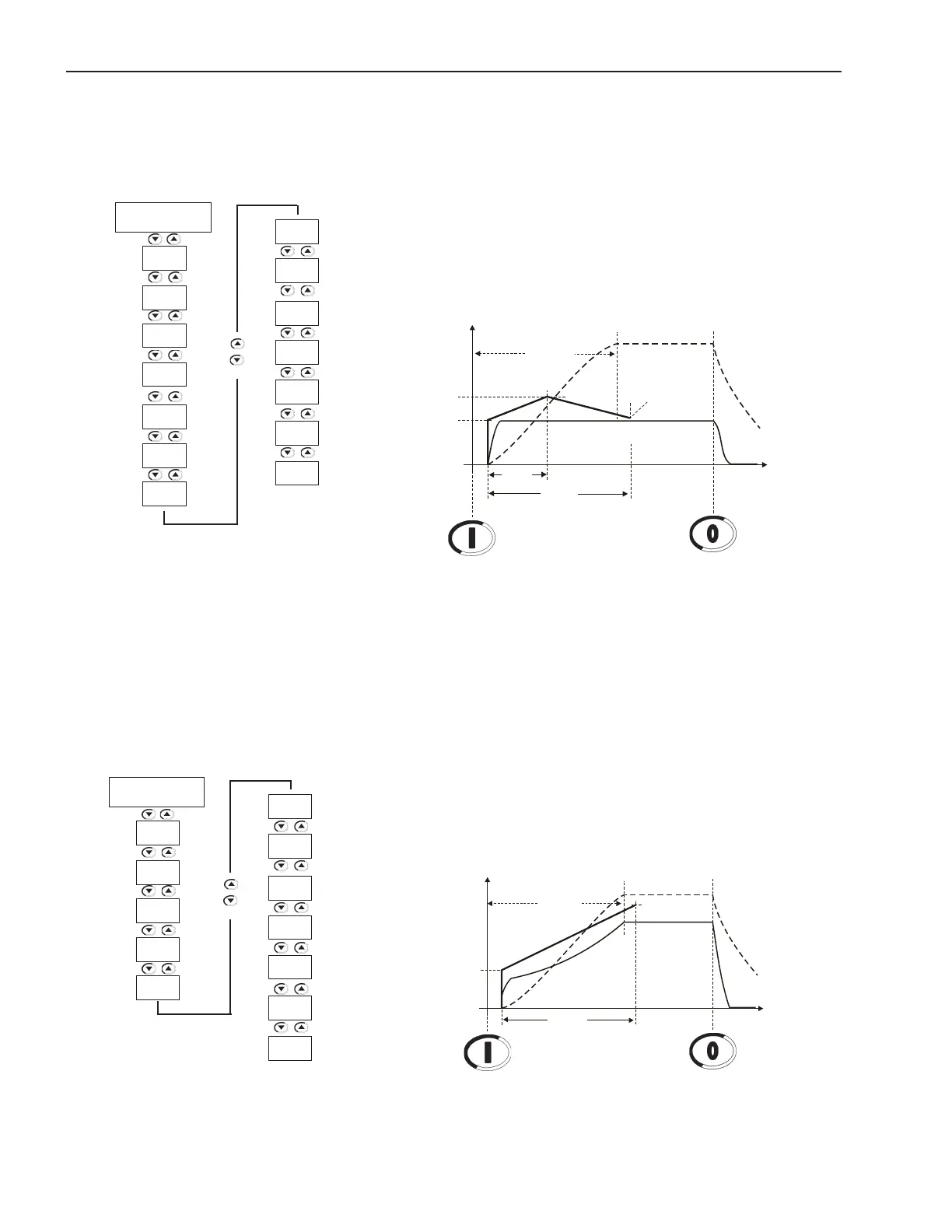

7.1.6.3LoadswithConstant

Torque and S Speed

Curve (P202=3 and 120=3

points)

1) Through the load curve you can set the torque 10% to 20% higher

than the load torque for the initial and the end points, P121 and

P122, and 30% to 40% higher than load torque for the middle

point P123;

2) Maintain P124 between 45% to 55% and set P102 according to

the starting time;

3) Fortherststartyoucanuseaspeedmeasuringinstrument,thus

ensuring the desired acceleration or the desired speed curve;

4) If no load curve is available, but you are sure that the torque is

constant, you can use the torque limit, P120=1 for executing the

rststartsandchangingtothisfunctionafterwards.

Figure 7.13 - Starting with quadratic torque control, 3 points, with constant load

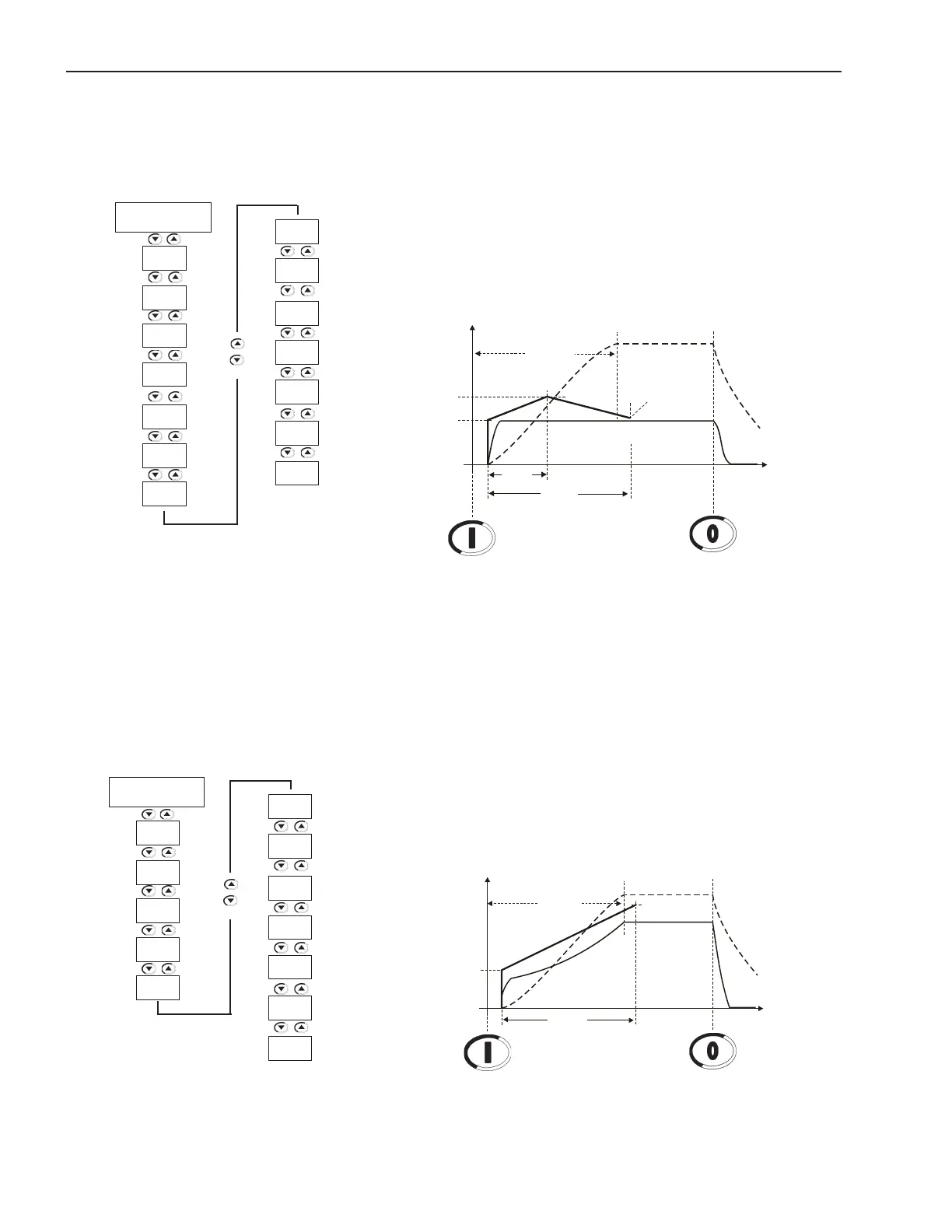

7.1.6.4 LoadswithQuadratic

Torque and S Speed

Curve

(P202=3 and P120=2

points)

1) Through the linear torque ramp you can obtain a speed curve

very similar to a S-curve with quadratic load, but not very steep;

2) Through the load curve you can set the torque 10% to 20%

higher than the load torque for the initial point P121, and 20%

to 30% higher than the load torque for the end point, P122;

3) If no load curves are available, proceed as follows:

3.1) Set P121 to the required torque to start rotating the motor +

load;

3.2) Set P122 to 110% to 130% of the nominal motor torque;

3.3) AtrstsetP102tolowvalues,10sto15sandthenndthebest

value.

Figure 7.14 - Starting with linear torque control, 2 points, quadratic load

Tn(%)

Start

Speed

P124

0

Enable

Disable

t(s)

Maximum Time

P121

Tn Nominal

LoadTorque

Torque Control

P123

P102

P122

P120 =3

P102

Torque

Control

P401

P400

P122

P121

P640

P406

P404

P402

P405

P123

P124

P104 =0

Tn(%)

Start

Speed

0

Enable

Disable

t(s)

Maximum Time

P121

Tn Nominal

LoadTorque

Torque Control

P102

P122

P401

P400

P640

P406

P404

P402

P405

P120 =2

P102

Torque

Control

P122

P121

P104 =0

Loading...

Loading...