6-134

Gain Adjustments at Minimum Output Frequency

Operate the motor at the minimum output frequency. Increase C5-03 (ASR proportional gain 2) to a level

where there is no oscillation. Decrease C5-04 (ASR integral time 2) to a level where there is no oscillation.

Monitor the Drive's output current and verify that it is less than 50% of the Drive rated current. If the output

current exceeds 50% of the Drive's rated current, decrease C5-03 and increase C5-04.

Gain Adjustments at Maximum Output Frequency

Operate the motor at the maximum output frequency. Increase C5-01 (ASR proportional gain 1) to a level

where there is no oscillation. Decrease C5-02 (ASR integral time 1) to a level where there is no oscillation.

Fine Adjustments

When you want even finer gain adjustment, adjust the gain while observing the speed waveform. The adjust-

ment method is the same as that for vector control.

Enable integral operation during acceleration and deceleration (by setting F1-07 to 1) when you want the

motor speed to closely follow the frequency reference during acceleration and deceleration. Reduce the setting

of C5-01 if overshooting occurs during acceleration, and reduce the setting of C5-03 and increase the setting

of C5-04 if undershooting occurs when stopping. If overshooting and undershooting cannot be eliminated by

adjusting only the gain, reduce the value of C5-05 speed control and reduce the limit of the frequency refer-

ence compensation value.

Droop Control Function

Droop control is a function that allows the user to set the amount of motor slip.

When a single load is operated with two motors (such as in a crane conveyor), a high-resistance motor is nor-

mally used. This is to use torque characteristics that exhibit proportion movements due to changes in the sec-

ondary resistor to maintain torque balance with the load and overall speed balance with the load.

If droop control is used, a high-resistance motor characteristics can be set for a general-purpose motor.

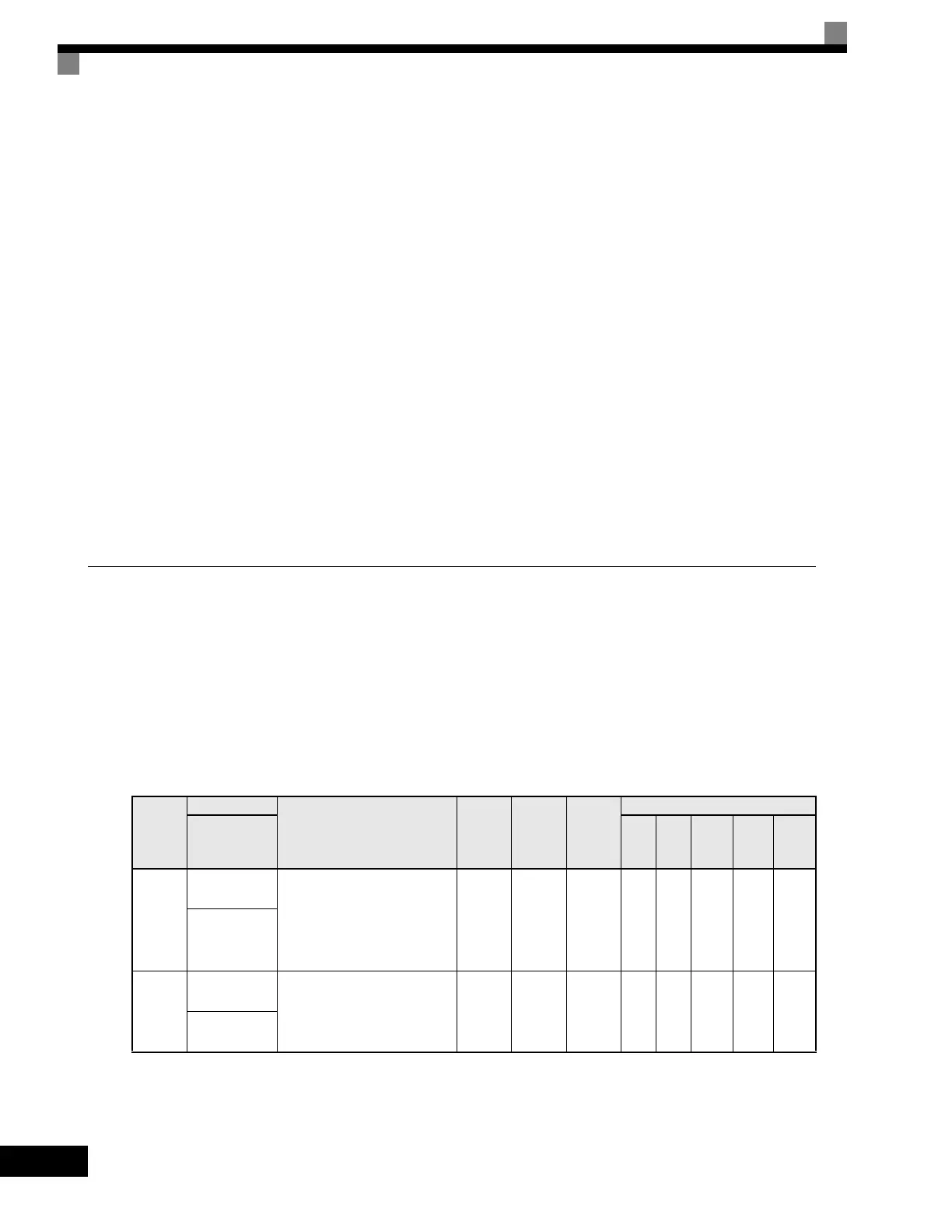

Related Parameters

Parameter

Number

Name

Description

Setting

Range

Factory

Setting

Change

during

Operation

Control Methods

Display

V/f

V/f

with

PG

Open

Loop

Vector

1

Flux

Vector

Open

Loop

Vector

2

b7-01

Droop Control

Level

Sets the speed decrease as a

percentage of motor base speed

(E1-06) when the motor is at

100% load torque. Setting of 0.0

disables droop control.

0.0

to

100.0

0.0 Yes No No No A A

Droop Quantity

b7-02

Droop Control

Delay Time

Determines the droop control

delay time in response to a load

change.

0.03

to

2.00

0.05secNoAAAAA

Droop Delay

Time

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...