Maintenance and Inspection

8-3

Periodic Maintenance of Parts

The Drive is configured of many parts, and these parts must be operating properly in order to make full use of

the Drive functions.

Among the electronic components, there are some that require maintenance depending on their usage condi-

tions. In order to keep the Drive operating normally over a long period of time, it is necessary to perform

period inspections and replace parts according to their service life.

Periodic inspection standards vary depending the Drive's installation environment and usage conditions. The

Drive's maintenance periods are noted below. Keep them as reference.

Note The standard replacement period is based on the following usage conditions:

Ambient temperature:Yearly average of 30°C

Load factor: 80% max.

Operating rate: 12 hours max. per day

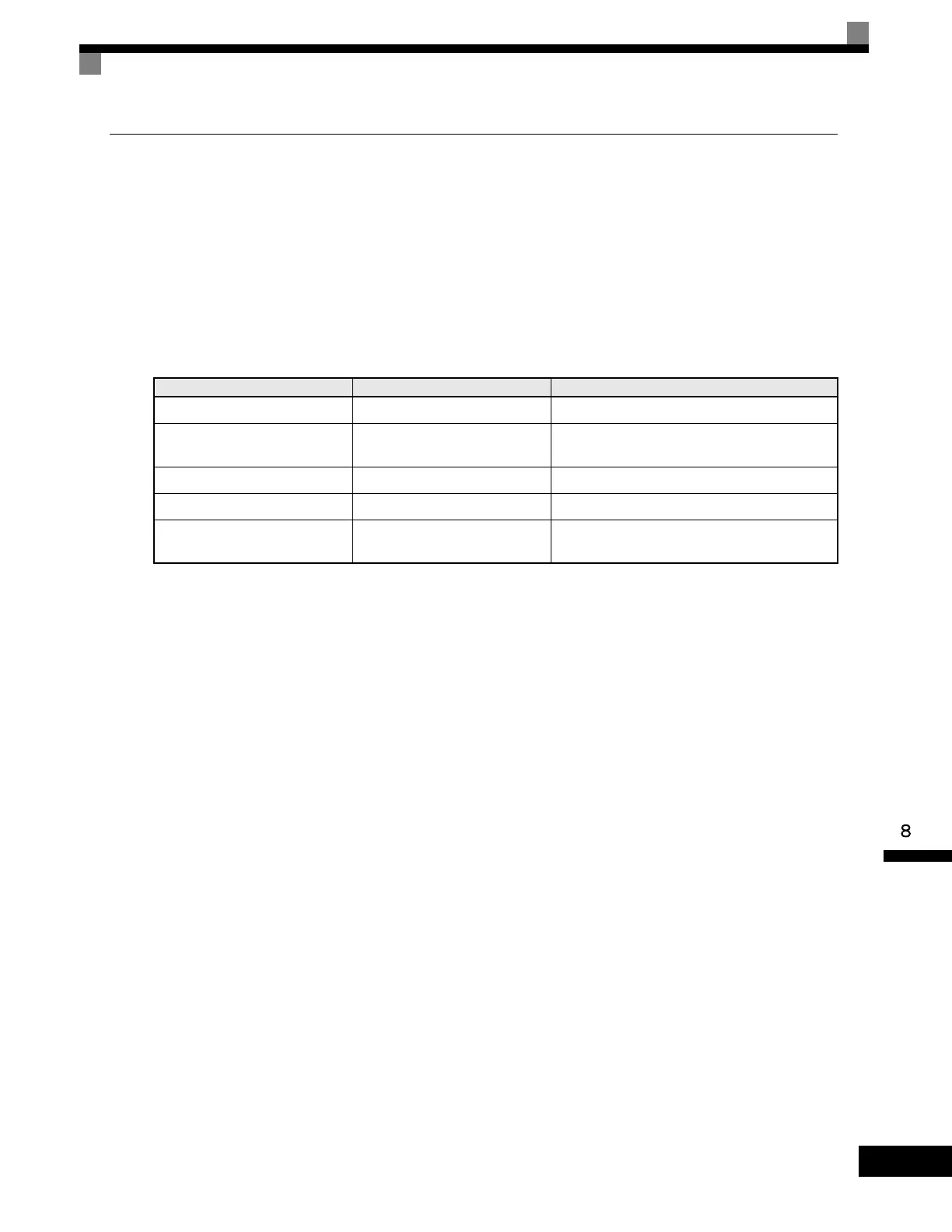

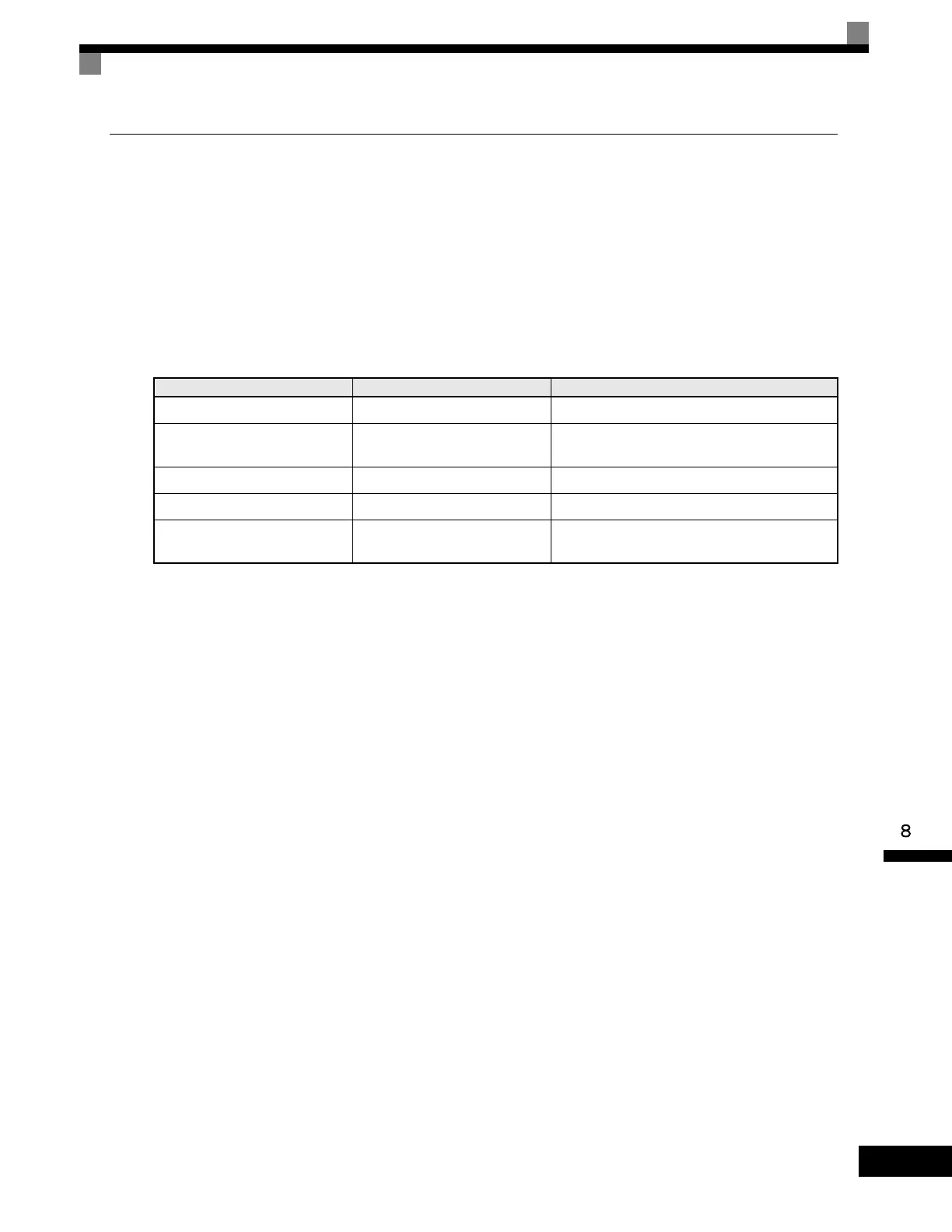

Table 8.2 Part Replacement Guidelines

Part Standard Replacement Period Replacement Method

Cooling fan 2 to 3 years Replace with new part.

Smoothing capacitor 5 years

Replace with new part. (Determine need by

inspection.)

Breaker relays - Determine need by inspection.

Fuses 10 years Replace with new part.

Aluminum capacitors on PCBs 5 years

Replace with new board. (Determine need by

inspection.)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...