7

Absolute Position Detection

7.2.2

Setting Related Parameters

7-4

7.2.2 Setting Related Parameters

This section explains absolute position detection parameters in the MP2200/MP2300 parameters.

Set the following MP2200/MP2300 parameters and SERVOPACK parameters prior to startup the

absolute position detection system.

( 1 ) MP2200/MP2300 Parameters

( 2 ) SERVOPACK Parameters

• The parameters for which IMPORTANT precautions are provided must be set. If they are not set correctly,

the current position after turning ON the power supply may not be correct.

Machine damage may occur. Set these parameters carefully.

CAUTION

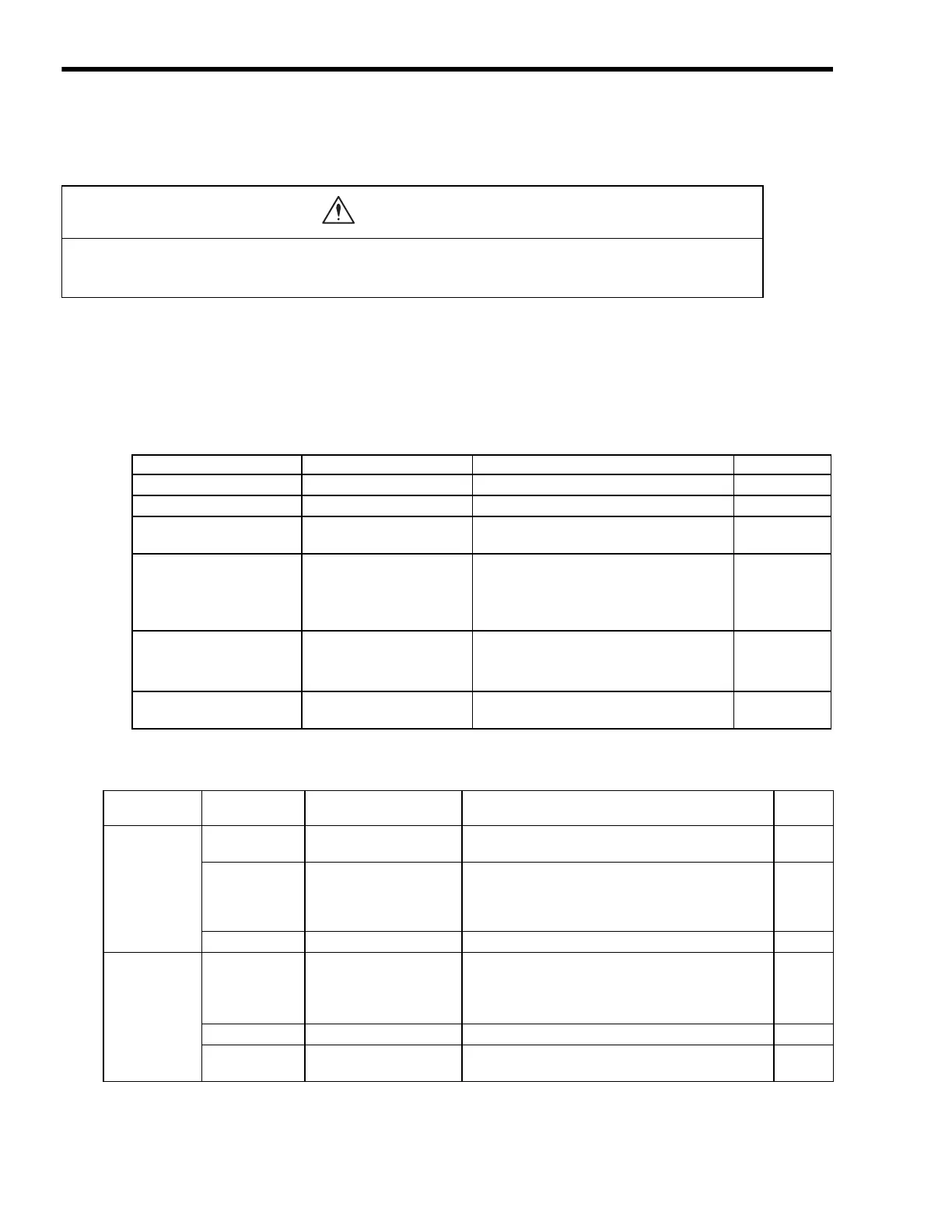

Table 7.1 MP2200/MP2300 Parameters

Parameter No. Name Setting Range Units

Fixed Parameter 1, bit 0 Axis Type

0: Finite length axis, 1: Infinite length axis −

Fixed Parameter 1, bit 9 Simple ABS Infinite Axis

0: Disable, 1: Enable −

Fixed Parameter 10

Maximum Value of Rotary

Counter

1 to 2

31

−

1

1 = 1 reference

unit

Fixed Parameter 30 Encoder Type

• Incremental encoder

• Absolute encoder

• Absolute encoder

(used as incremental encoder)

−

Fixed Parameter 36 Encoder Resolution

1 to 2

31

−

1

Set the value after multiplication. (For a 16-bit

encoder, set 2

16

= 65536.)

pulse

Fixed Parameter 38

Max. Revolutions of

Absolute Encoder

0 to 2

31

−

1

1 = 1 rotation

SERVOPACK

Model

Parameter Name Setting Range Units

Σ

Series

*

Cn-0001, bit E

Encoder Selection

0: Incremental encoder

1: Absolute encoder

−

Cn-0002, bit 0

Rotation Direction

Selection

0: Sets counterclockwise (CCW) rotation as forward

rotation.

1: Sets clockwise (CW) rotation as forward rotation

(reverse rotation mode).

−

Cn-0011

Number of Encoder Pulses 513 to 32767 P/R

Σ

-II Series

*

Pn000.0

Direction Selection

0: Sets counterclockwise (CCW) rotation as forward

direction.

1: Sets clockwise (CW) rotation as forward direction

(reverse rotation mode).

−

Pn205

Multiturn Limit Setting 0 to 65535 Rev

Pn002.2

Absolute Encoder Usage

0: Uses absolute encoder as an absolute encoder.

1: Uses absolute encoder as an incremental encoder.

−

WWW.NNC.IR

Loading...

Loading...