188 ZXP Series 7 Card Printer Service Manual P1036102-007

Replacement Procedures for the Printer

Procedures: Torque Tools Calibration Instructions

Procedure

Step 1. Securely fasten the Knob onto a turntable with a motor rated at 30rpm.

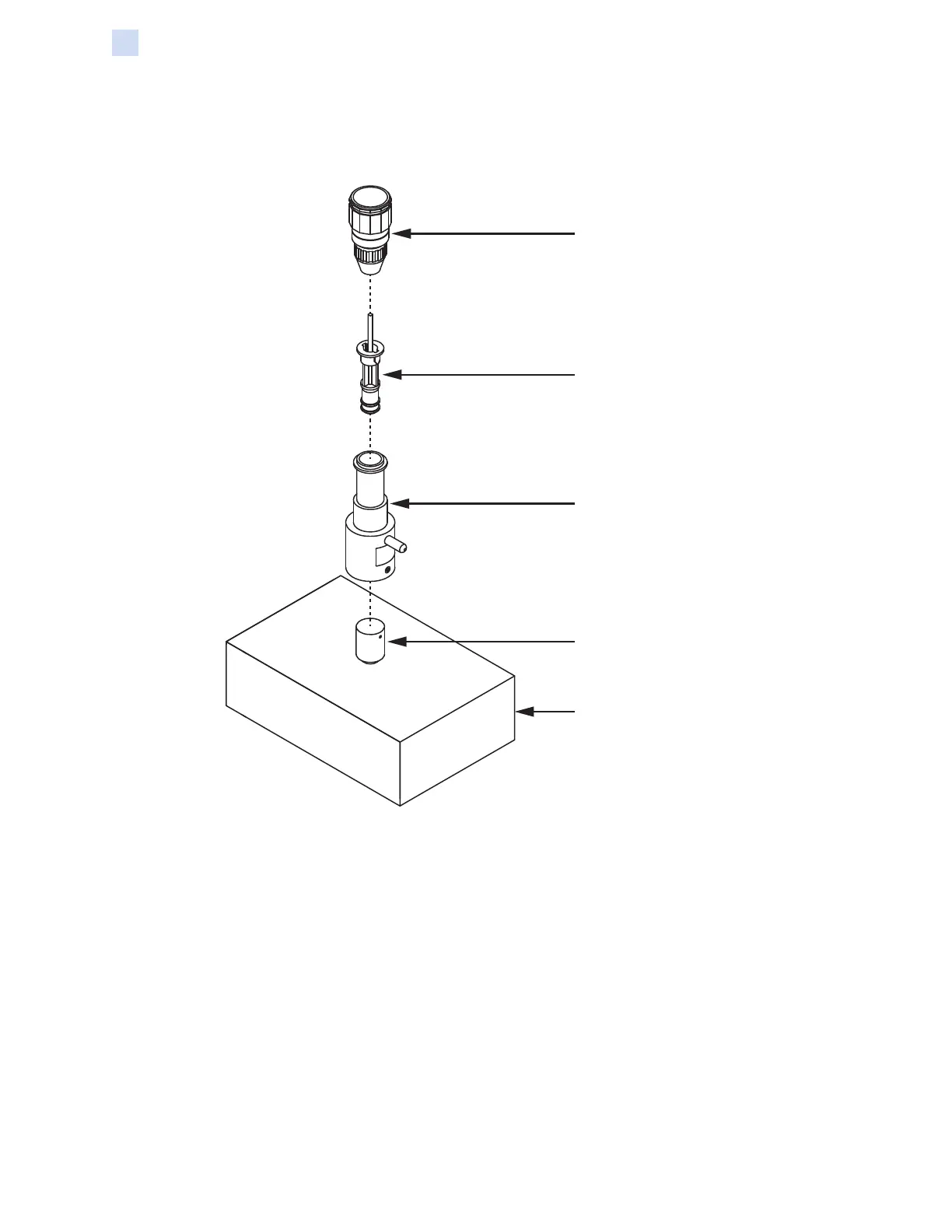

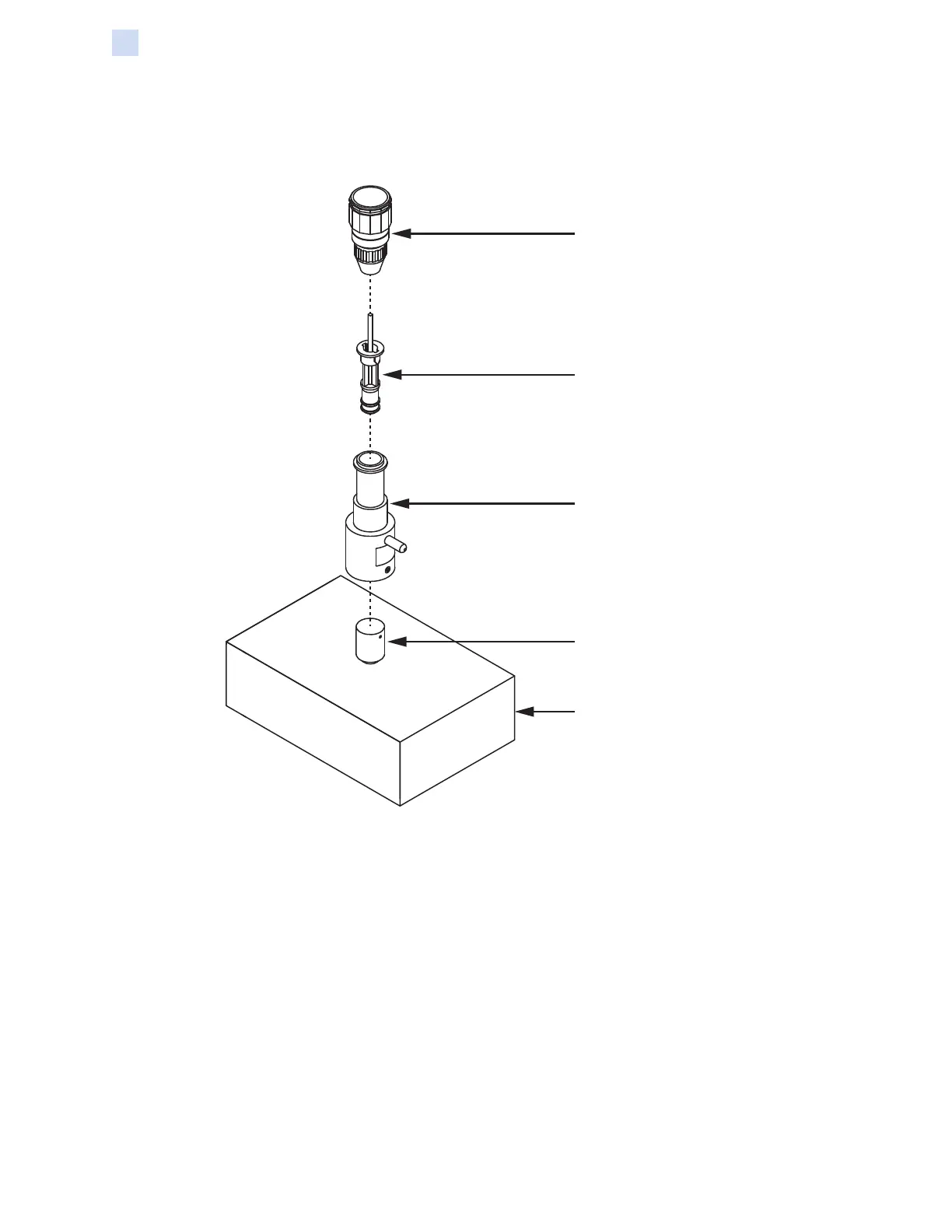

Torque Watch

Spindle Assembly

(Spindle and Shaft)

Torque Tool

(High Torque or Low Torque)

Knob

Turntable

Step 2. Align the Torque Tool’s ball set screws with the Knob’s divets, and insert

the Torque Tool being tested onto the Knob. Ensure the ball set screws are

securely seated in divets of the Knob.

Step 3. Prepare the Spindle Assembly by attaching the Spindle to the Shaft with the

screw and washer included in the kit.

Step 4. Insert the Shaft into the Torque Watch. Tighten the Torque Watch to the shaft

following the manufacturers instructions for the Torque Watch in use.

Step 5. Hold the Torque Watch in the vertical position, and insert Spindle into the

Torque Tool being tested.

Step 6. Ensuring that the Torque Watch needle is on the zero of the dial, turn on the

turntable, following the manufacturers instructions for he turntable in use.

Loading...

Loading...