START-UP

Carl Zeiss Changing the mechanical stage Axio Imager

68 430000-7344-001 M70-2-0020 e 06/2009

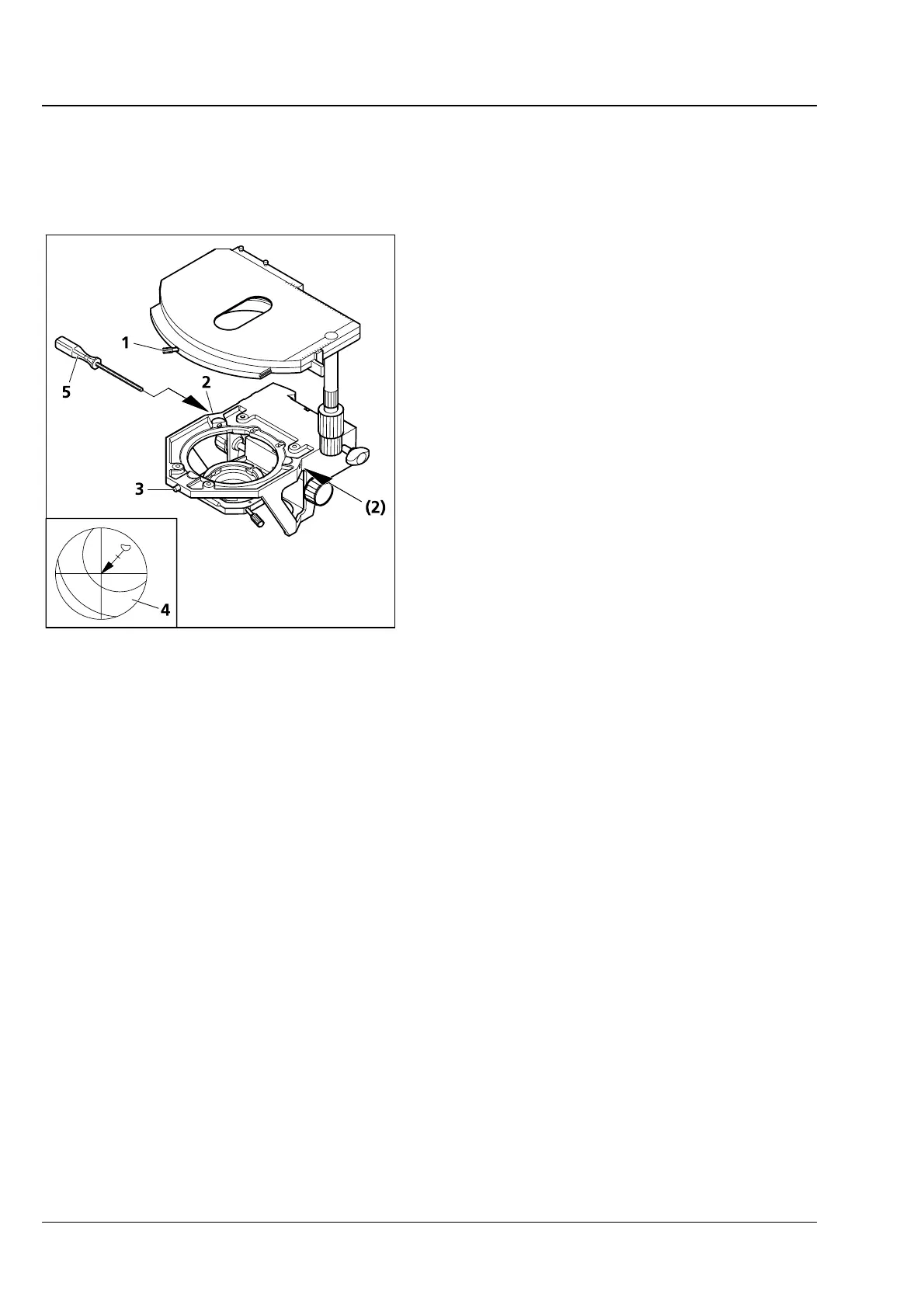

• Press the stage to the front against the spring pin and lower it towards the back of stage carrier

(

3-52/2), and then release it.

• Retighten screw cap (3-52/3).

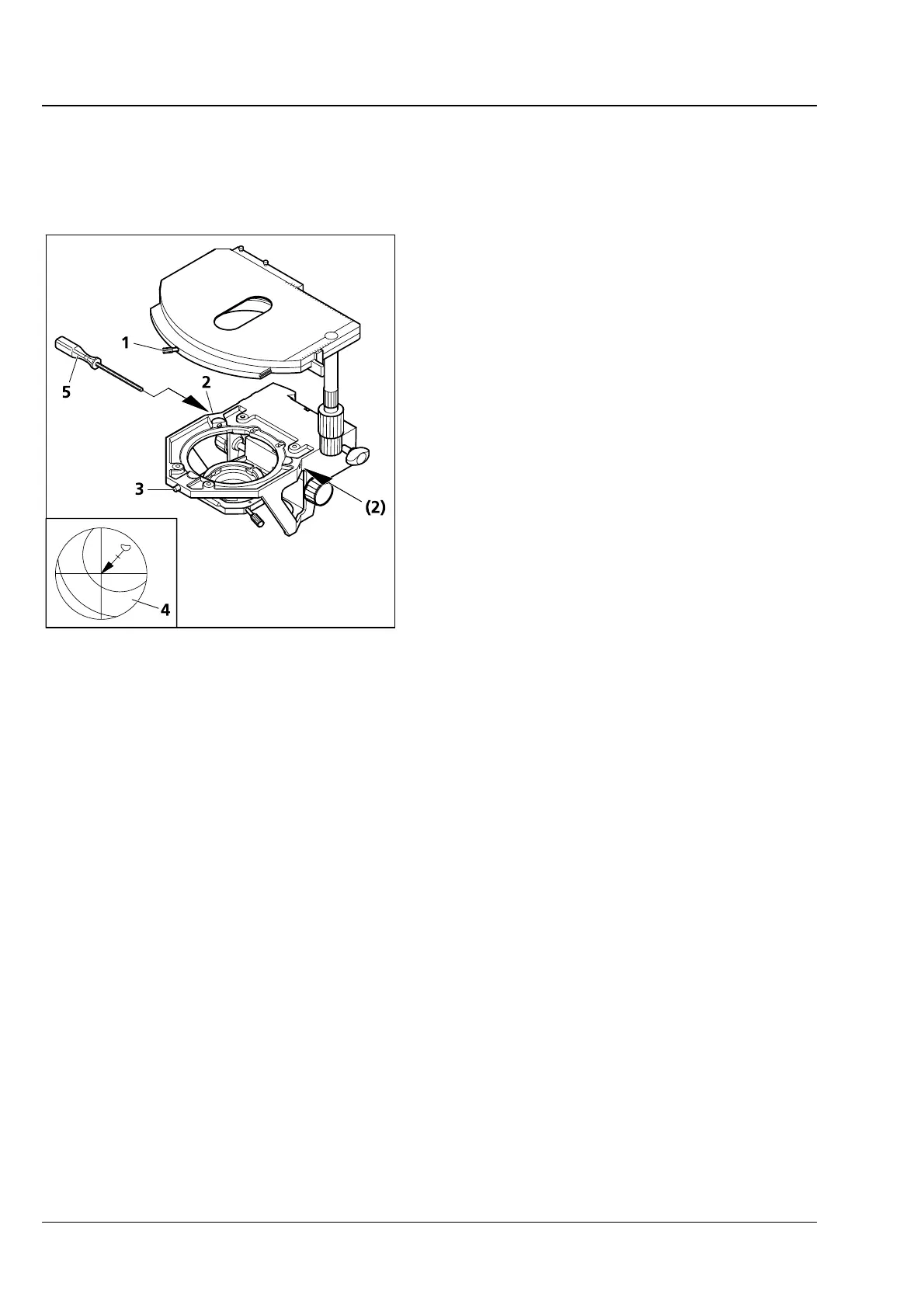

(3) Centering the stage

When objectives with high magnification are used,

centering can be exact for one selected objective

only.

All stages are factory-precentered, i.e. a set

specimen detail remains in the image center when

the stage is rotated. If the image detail moves from

the image center (

3-53/4), while you rotate the

stage, recenter the stage as follows:

• Loosen stage clamping screw (3-53/1) and the

screw cap on the stage carrier (

3-53/3).

• Rotate the stage to determine the maximum

specimen deflection (

3-53/4, tip of arrow) to

the eyepiece reticle.

• Reset the two centering screws on the stage

carrier (

3-53/2) using one SW 1.5 Allen screw-

driver (

3-53/5) each to move the specimen

detail by half the arrow length in the direction

of the crossline center. Check whether the

specimen detail moves when the stage is

rotated again; repeat the procedure, when

required.

• When centering is finished, tighten screw cap

(

3-53/3) again.

The stage can be turned through 240° up to a motion range of y ≤ 27 mm. No rotation is possible above

this range of movement.

3.33.3 Adjusting the travel range on ergonomic drive

On mechanical stages with ergo-drive, the length of the x and y stage drive can be extended by

max. 15 mm by axial movement of the drive knobs to further improve operating ease.

Fig. 3-53 Centering the rotary mechanical

stage

Loading...

Loading...