236 Actual signals and parameters

3717 LOAD TORQ

LOW 5

Defines the torque value of the fifth underload curve

definition point. Must be smaller than 3718 LOAD TORQ

HIGH 5.

30%

0…600% Torque 1 = 1%

3718 LOAD TORQ

HIGH 5

Defines the torque value of the fifth overload curve definition

point

300%

0…600% Torque 1 = 1%

40 PROCESS PID

SET 1

Process PID (PID1) control parameter set 1. See section

PID control on page 138.

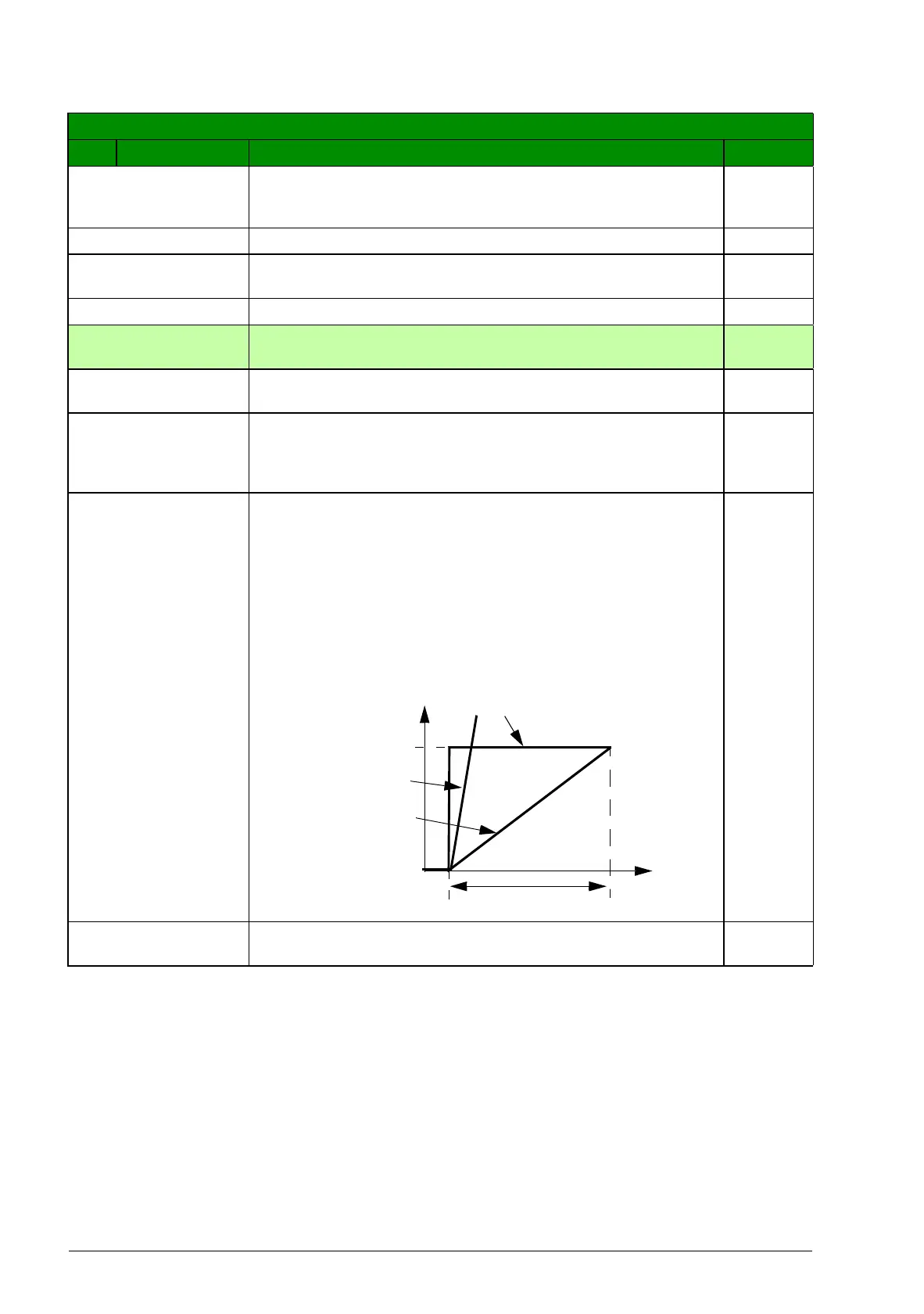

4001 GAIN Defines the gain for the process PID controller. High gain

may cause speed oscillation.

1.0

0.1…100.0 Gain. When value is set to 0.1, the PID controller output

changes one-tenth as much as the error value. When value

is set to 100, the PID controller output changes one hundred

times as much as the error value.

1 = 0.1

4002 INTEGRATION

TIME

Defines the integration time for the process PID1 controller.

The integration time defines the rate at which the controller

output changes when the error value is constant. The

shorter the integration time, the faster the continuous error

value is corrected. Too short an integration time makes the

control unstable.

60.0 s

0.0 = NOT SEL

0.1…3600.0 s

Integration time. If parameter value is set to zero, integration

(I-part of the PID controller) is disabled.

1 = 0.1 s

All parameters

No. Name/Value Description Def/FbEq

t

A = Error

B = Error value step

C = Controller output with gain = 1

D = Controller output with gain = 10

D (4001 = 10)

C (4001 = 1)

B

A

4002

Loading...

Loading...