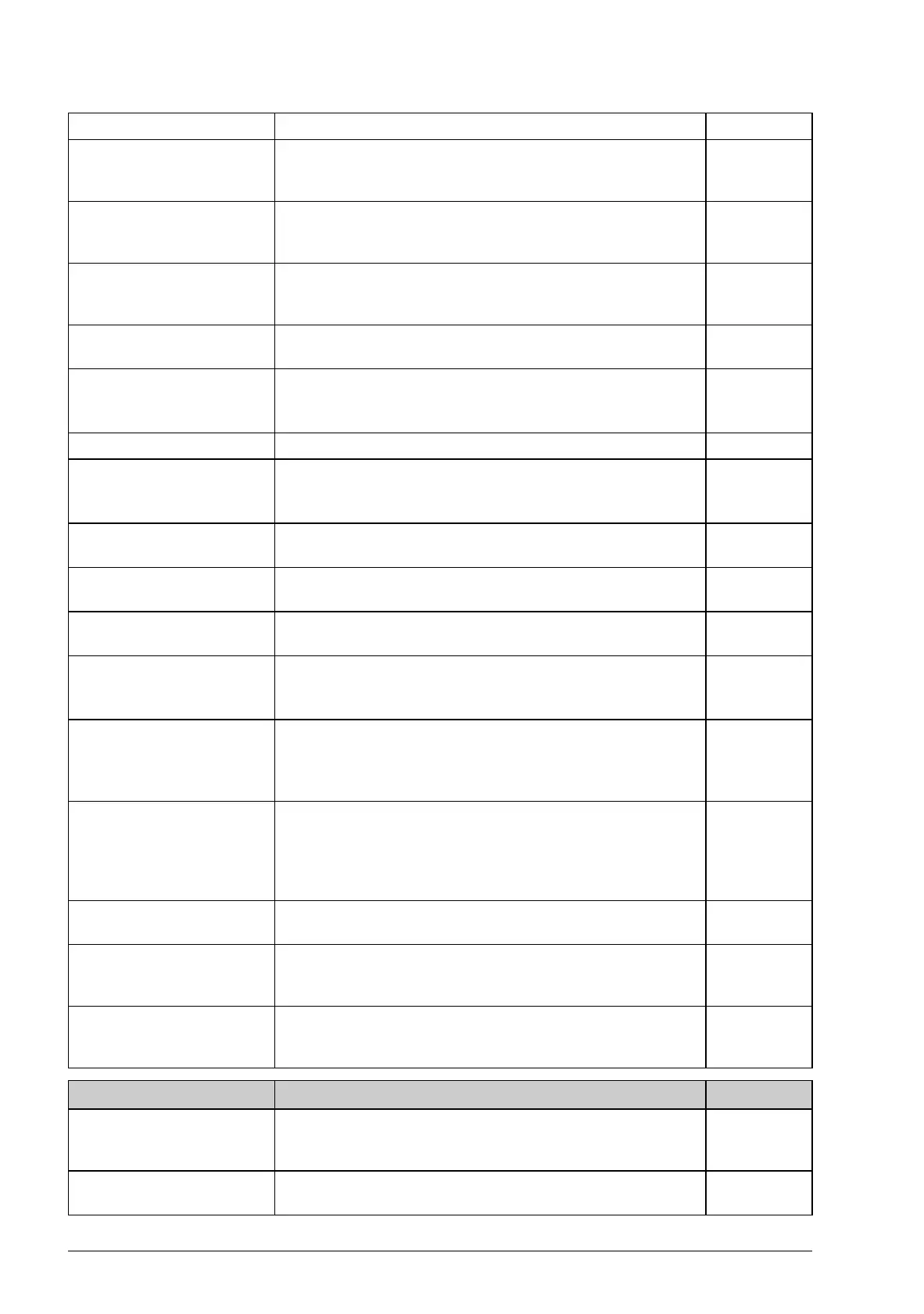

104 Parameters

01.25 kWh supply Amount of energy that the drive has taken from (or given to)

the AC supply in kilowatt-hours. Can be reset by entering 0

using the DriveStudio PC tool.

1 = 1 kWh

01.26 On-time counter On-time counter. The counter runs when the drive is

powered. Can be reset by entering 0 using the DriveStudio

PC tool.

1 = 1 h

01.27 Run-time counter Motor run-time counter. The counter runs when the inverter

modulates. Can be reset by entering 0 using the DriveStudio

PC tool.

1=1h

01.28 Fan on-time Running time of the drive cooling fan. Can be reset by

entering 0 using the DriveStudio PC tool.

1 = 1 h

01.29 Torq nom scale Nominal torque which corresponds to 100%.

Note: This value is copied from parameter 99.12 Mot nom

torque if entered. Otherwise the value is calculated.

1000 =

1N•m

01.30 Polepairs Calculated number of pole pairs in the motor. 1 = 1

01.31 Mech time const Mechanical time constant of the drive and the machinery as

determined by the speed controller autotune function.

See parameter 23.20 PI tune mode.

1000 = 1 s

01.32 Temp phase A Measured temperature of phase U power stage in percent of

fault limit.

10 = 1%

01.33 Temp phase B Measured temperature of phase V power stage in percent of

fault limit.

10 = 1%

01.34 Temp phase C Measured temperature of phase W power stage in percent

below fault limit.

10 = 1%

01.35 Saved energy Energy saved in kWh compared to direct-on-line motor

connection.

See parameter group 45 Energy optimising on page 230.

1 = 1 kWh

01.36 Saved amount Monetary savings compared to direct-on-line motor

connection. This value is a multiplication of parameters 01.35

Saved energy and 45.02 Energy tariff1.

See parameter group 45 Energy optimising on page 230.

1 = 1

01.37 Saved CO2 Reduction in CO

2

emissions in metric tons compared to

direct-on-line motor connection. This value is calculated by

multiplying the saved energy in MWh by 45.07 CO2 Conv

factor (default 0.5 tn/MWh).

See parameter group 45 Energy optimising on page 230.

1 = 1 metric

ton

01.38 Temp int board Measured temperature of the interface board in degrees

Celsius.

10 = 1 °C

01.40 Speed filt Filtered result from 01.01 Motor speed rpm. The filtration time

is set with parameter 56.08 Speed filt time. This signal is not

used in motor control.

100 = 1 rpm

01.41 Torque filt Filtered result from 01.06 Motor torque. The filtration time is

set with parameter 56.09 Torque filt time. This signal is not

used in motor control.

10 = 1%

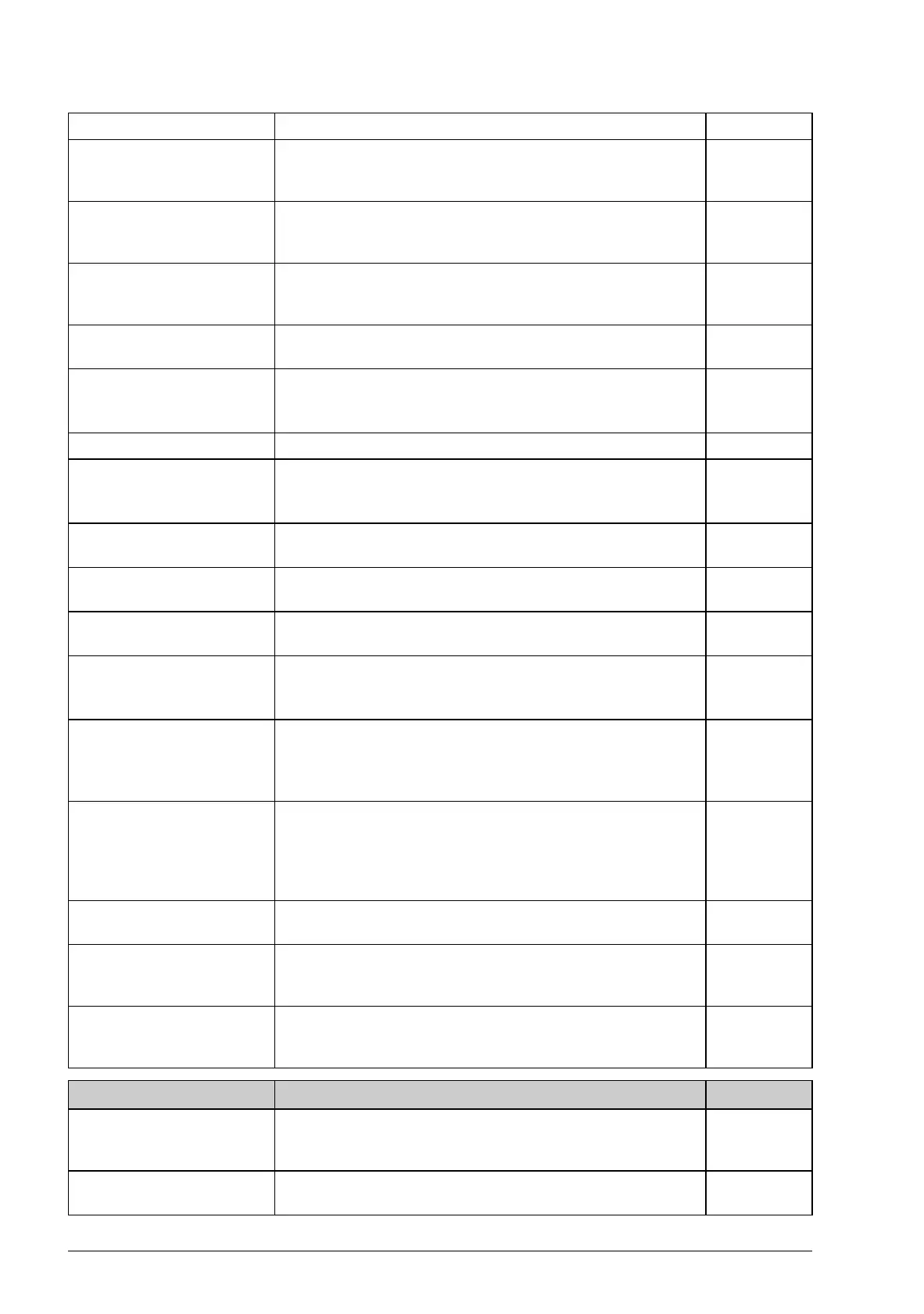

02

02 I/O values

Input and output signals.

02.01 DI status Status of digital inputs DI8…DI1. The 7th digit reflects the

start interlock input (DIIL). Example: 01000001 = DI1 and

DIIL are on, DI2…DI6 and DI8 are off.

-

02.02 RO status Status of relay outputs RO7…RO1. Example: 0000001 =

RO1 is energized, RO2…RO7 are de-energized.

-

No. Name/Value Description FbEq

Loading...

Loading...