94 Application macros

PID control macro

The PID control macro is suitable for process control applications, for example

closed-loop pressure, level or flow control systems such as

• pressure boost pumps of municipal water supply systems

• level-controlling pumps of water reservoirs

• pressure boost pumps of district heating systems

• material flow control on a conveyor line.

The process reference signal is connected to analog input AI1 and the process

feedback signal to AI2. Alternatively, a direct speed reference can be given to the

drive through AI1. Then the PID controller is bypassed and the drive no longer

controls the process variable.

Selection between direct speed control (control location EXT1) and process variable

control (EXT2) is done through digital input DI3.

The stop/start signals for EXT1 and EXT2 are connected to DI1 and DI6 respectively.

A constant speed (300 rpm) can be activated through DI4.

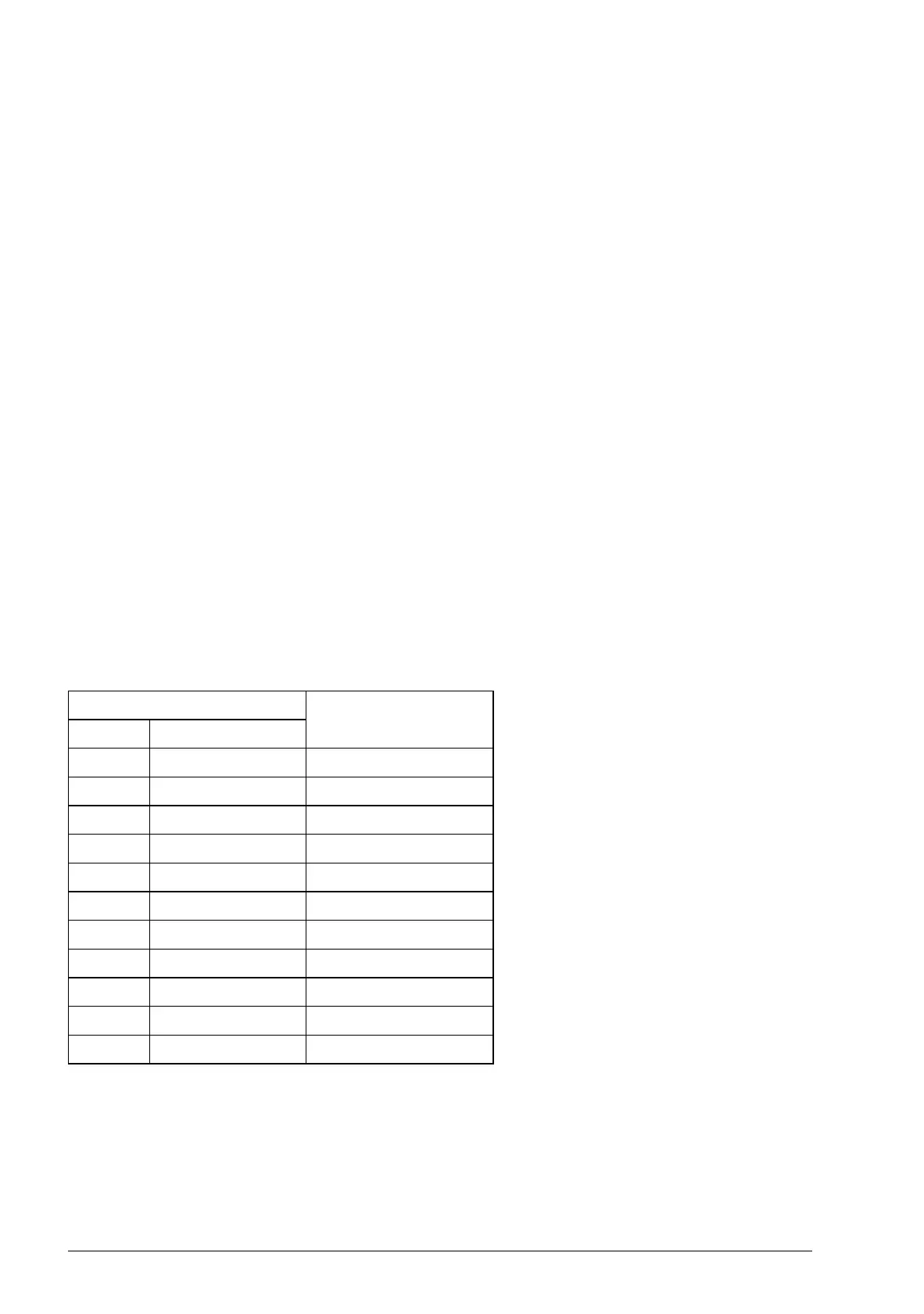

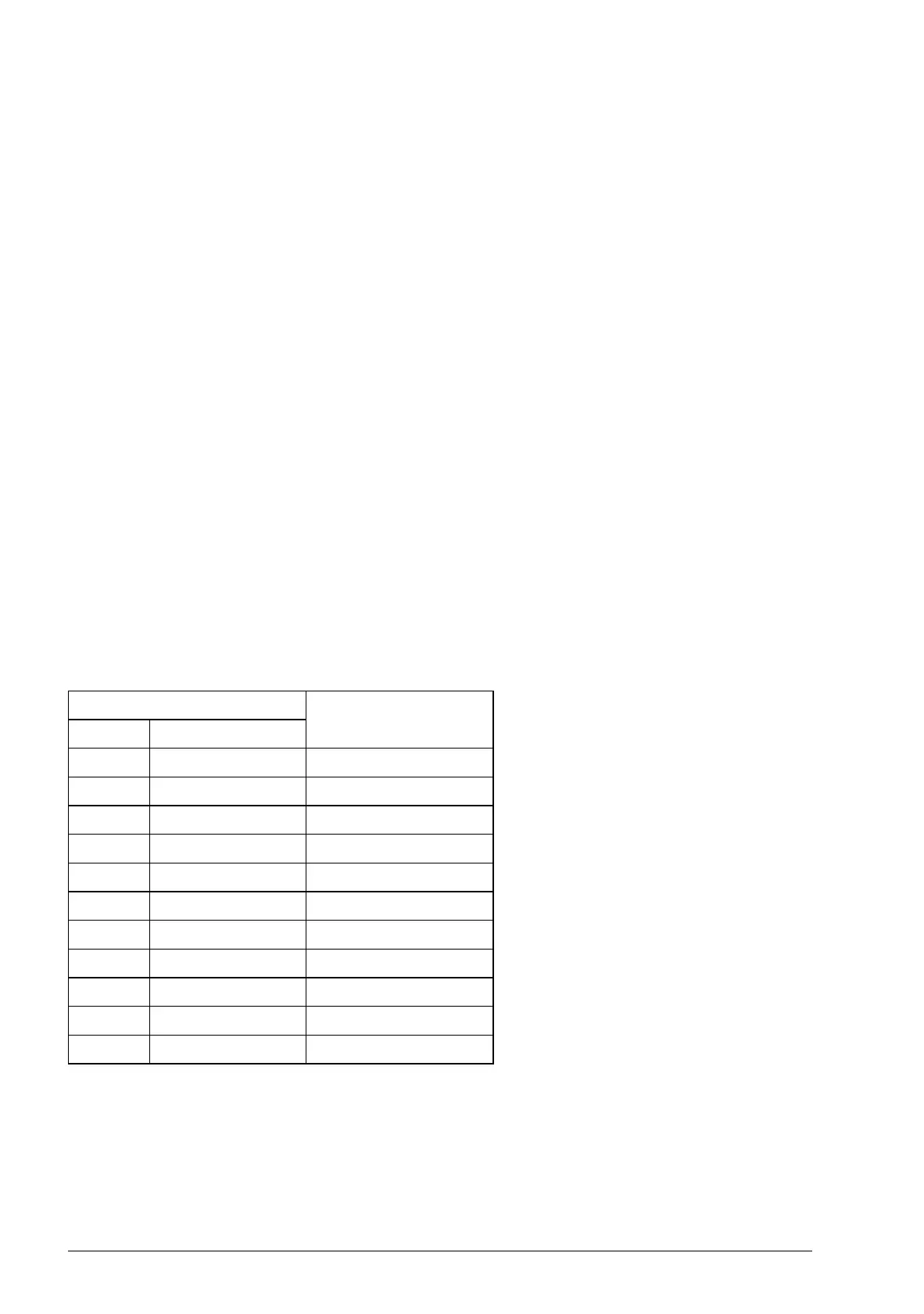

Default parameter settings for PID control macro

Below is a listing of default parameter values that differ from those listed in chapter

Additional parameter data (page 263).

Parameter

PID control macro

default

No. Name

10.04 Ext2 start func In1

10.05 Ext2 start in1 DI6

10.10 Fault reset sel C.FALSE

12.01 Ext1/Ext2 sel DI3

13.05 AI1 min scale 0.000

13.09 AI2 max scale 1500.000

13.10 AI2 min scale 0.000

21.02 Speed ref2 sel PID out

21.04 Speed ref1/2 sel DI3

26.02 Const speed sel1 DI4

26.06 Const speed1 300 rpm

Loading...

Loading...