Conveyor work area signals

DescriptionSignal

Digital output signal. This signal is used if an overflow shall be

avoided by letting the conveyor movement be controlled by

the work area. The signal goes high when the conveyor shall

start moving and goes low when the conveyor shall stop to

avoid an overflow.

Conveyor start/stop

Digital output signal. This signal is high when the queue for

this work area is empty. The signal goes high when the last

item is retrieved from the queue.

Queue idle

Digital output signal. This signal is high when there is one or

more items between the enter and exit limits for the work area.

Position available

Digital input signal that tells that it is time to generate a new

vision image or generate new predefined positions. This signal

is ignored if a distance triggered conveyor is used.

Position generator

If vision is used this digital output signal must be connected

to the trigger input on the I/O port on the camera. If predefined

positions are used this output signal must be connected directly

to the start input on the conveyor encoder board. This is best

done using the doManSyncX signal. If predefined positions are

distributed only to this work area (For instance, Runtime with

a single robot),the encoder signal cXSoftSyncSig can be used

instead of doManSyncX, that is, without the need of connecting

a signal to the start input of the encoder board.

Trig

This is the input signal name for the strobe signal and is the

start signal for the encoder board for the conveyor. The signal

name is set to cXNewObjStrobe. If vision is used the signal

must be generated from the strobe output on the I/O port of

the camera. When predefined positions are used, the strobe

may be generated directly from the doManSyncX signal, which

is directly connected to the start signal on the encoder board.

Strobe

Procedure

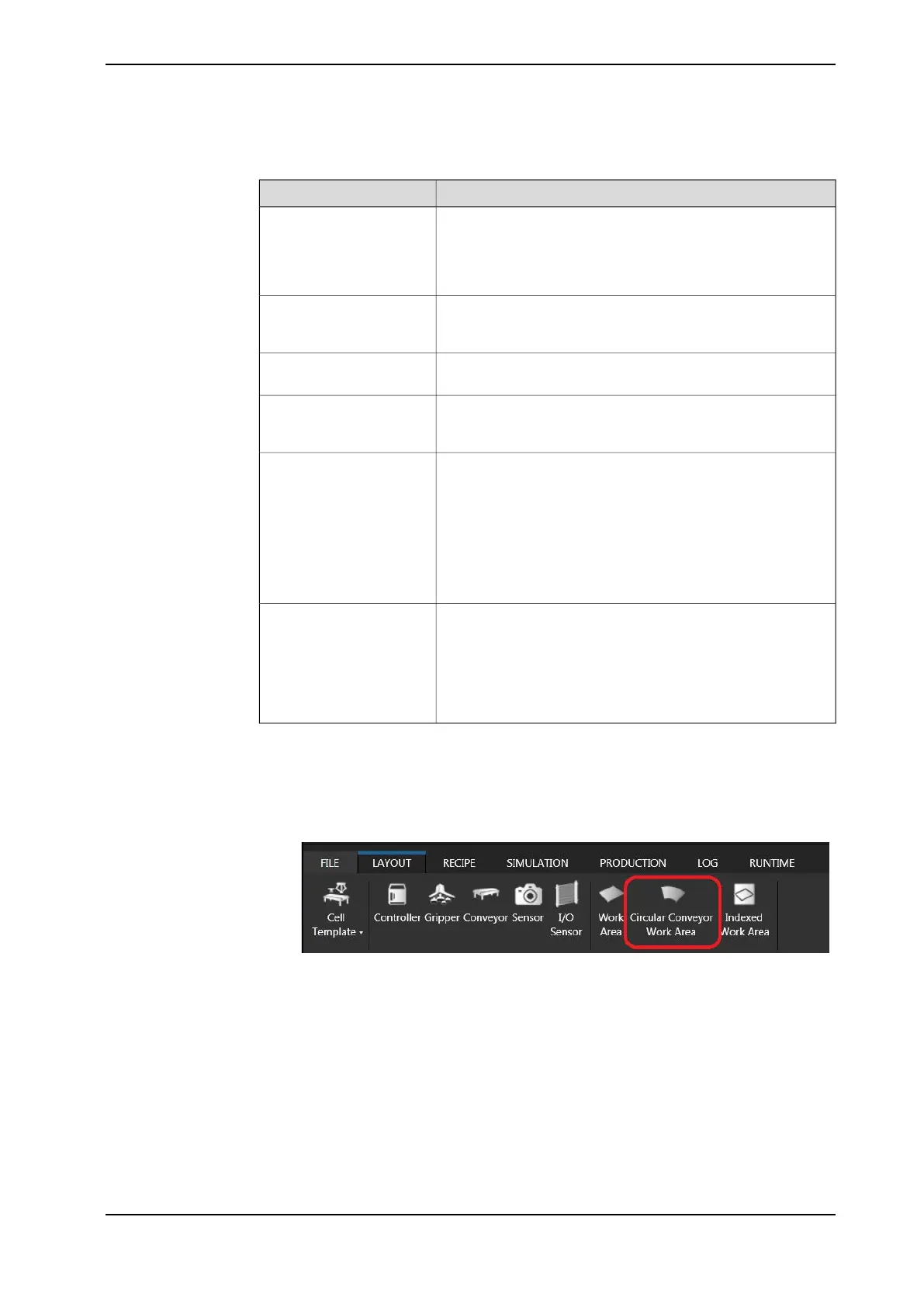

On the PickMaster PowerPac ribbon-tab, click Layout.

Use this procedure to a work area:

1 On the ribbon-tab, click Circular Conveyor Workarea.

xx1800001420

Continues on next page

Application manual - PickMaster® Twin - PowerPac 97

3HAC064218-001 Revision: B

© Copyright 2021 ABB. All rights reserved.

4 Working with PickMaster PowerPac

4.2.6 Adding work area

Continued

Loading...

Loading...