Over

view

Leak detection is used to detect

micro-openings,

porosities, etc. in test

parts. The detection of these cracks involves the use of

a

light

tracer

gas, which is

capable

of infiltrating the smallest leak quickly: Helium

.

The detector samples and measures the helium flow rate entering

the

test part via the

leak(s).

The testing method is selected

according

to the test part and

the

measurement accuracy required:

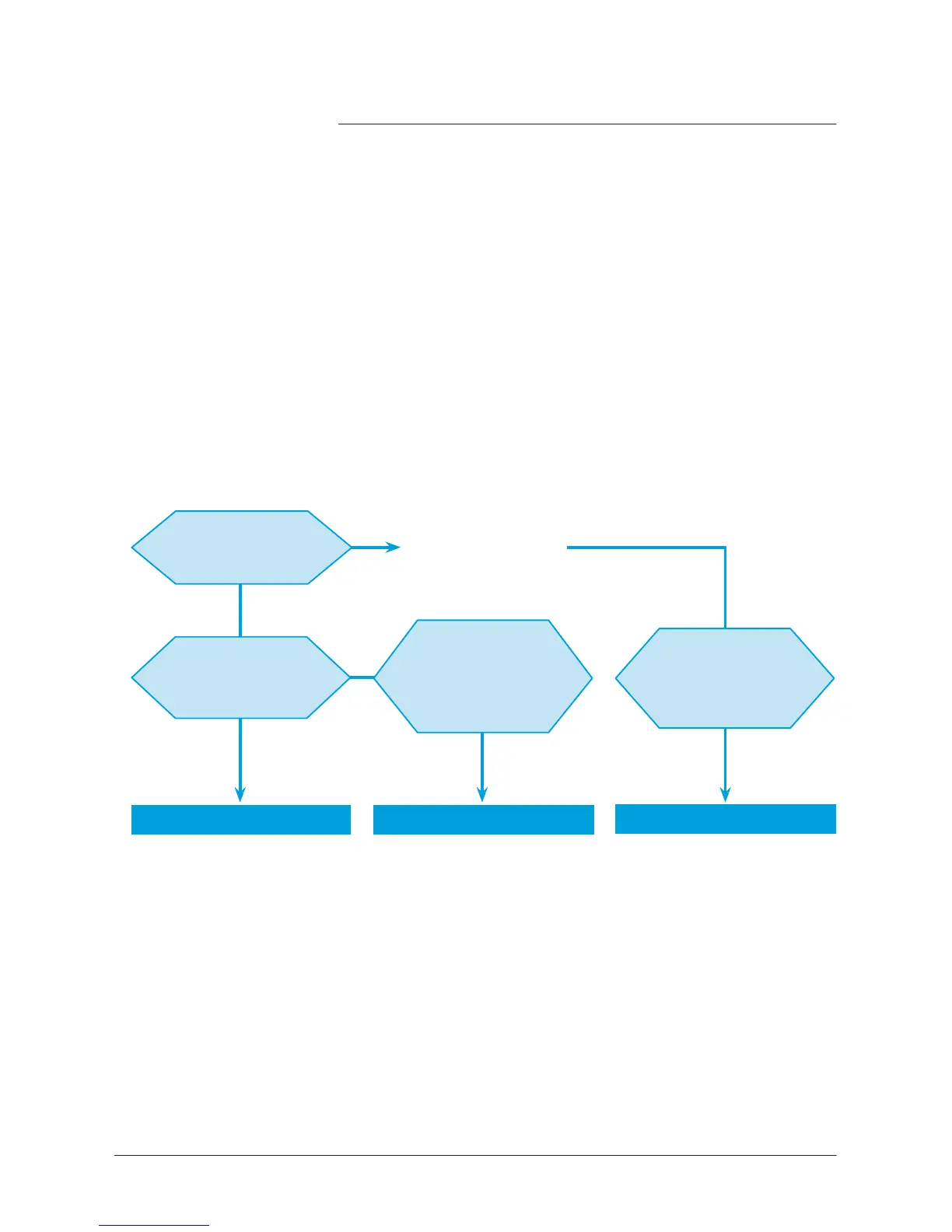

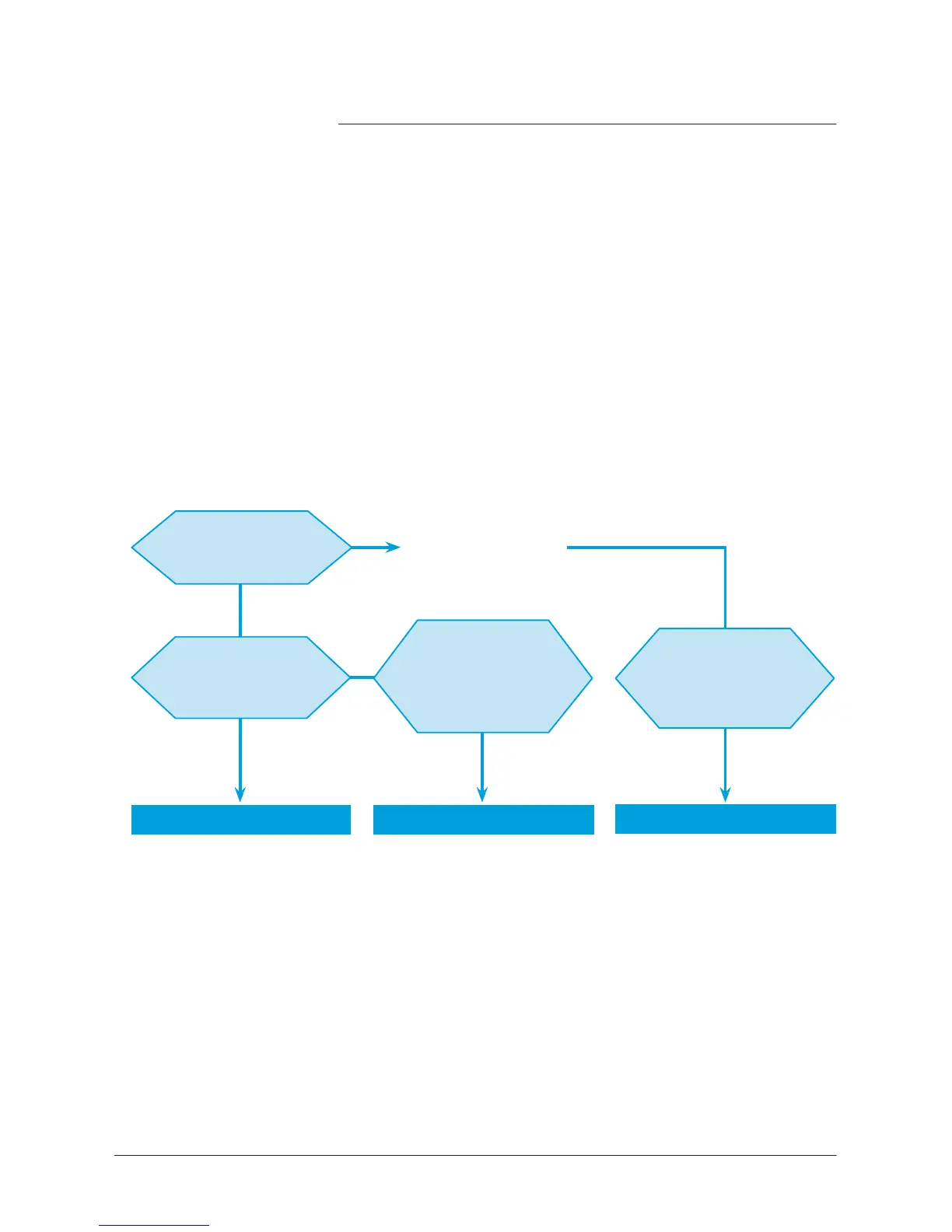

The part can

be

connected to

an evacuation line

no

The part is

sealed

yes

Its

characteristics

allow it to

be

evacuated

Its

characteristics

no

allow it to

be

pressurized

with helium

or

a

mixture

containing

helium

Its

characteristics

allow it to be

placed

in

a vacuum

vessel

yes

yes

yes

SPRAY

method

laeak rate

measurement

from

10

-10

to

10

-1

mbar.

l/s

and possibility of

locating the

leak.

SNIFFING

method

Minimum

detectable

leak of

10

-6

mbar.l/s

and possibility of

locating

the

leak.

BOMBING

method

The sensitivity is limited by

the

internal dead

volume of the part

as

well as on the bombing time and

the

pressurization value.

Global test without possible

location

of the

leak.

1

/4

Loading...

Loading...