HEXRCHardware Manual Installation and Configuration

2.2.2. Minimizing Conducted, Radiated, and System Noise

To reduce electrical noise, observe the following wiring techniques.

1. Use shielded cable to carry the motor current and tie the shield to the connector backshell.

2. Use a cable with sufficient insulation. This will reduce the capacitive coupling between the leads that,

in turn, reduces the current generated in the shield wire.

3. User connections to the product must be made using shielded cables with metal D-style connectors

and back shells. The shield of the cables must be connected to the metal back shell in order for the

product to conform to radiated emission standards.

4. The HEXRC is a component designed to be integrated with other electronics. EMC testing must be

conducted on the final product configuration.

2.2.3. I/O and Signal Wiring Requirements

The I/O, communication, and encoder feedback connections are typically very low power connections. In

some applications, especially when there are significant wire distances, a larger wire size may be required to

reduce the voltage drop that occurs along the wire. This increase may be necessary in order to keep the

voltage within a specified range at a remote point.

Low voltage and high voltage wires should be kept physically separated so that they cannot contact one

another. This reduces the risk of electric shock and improves system performance.

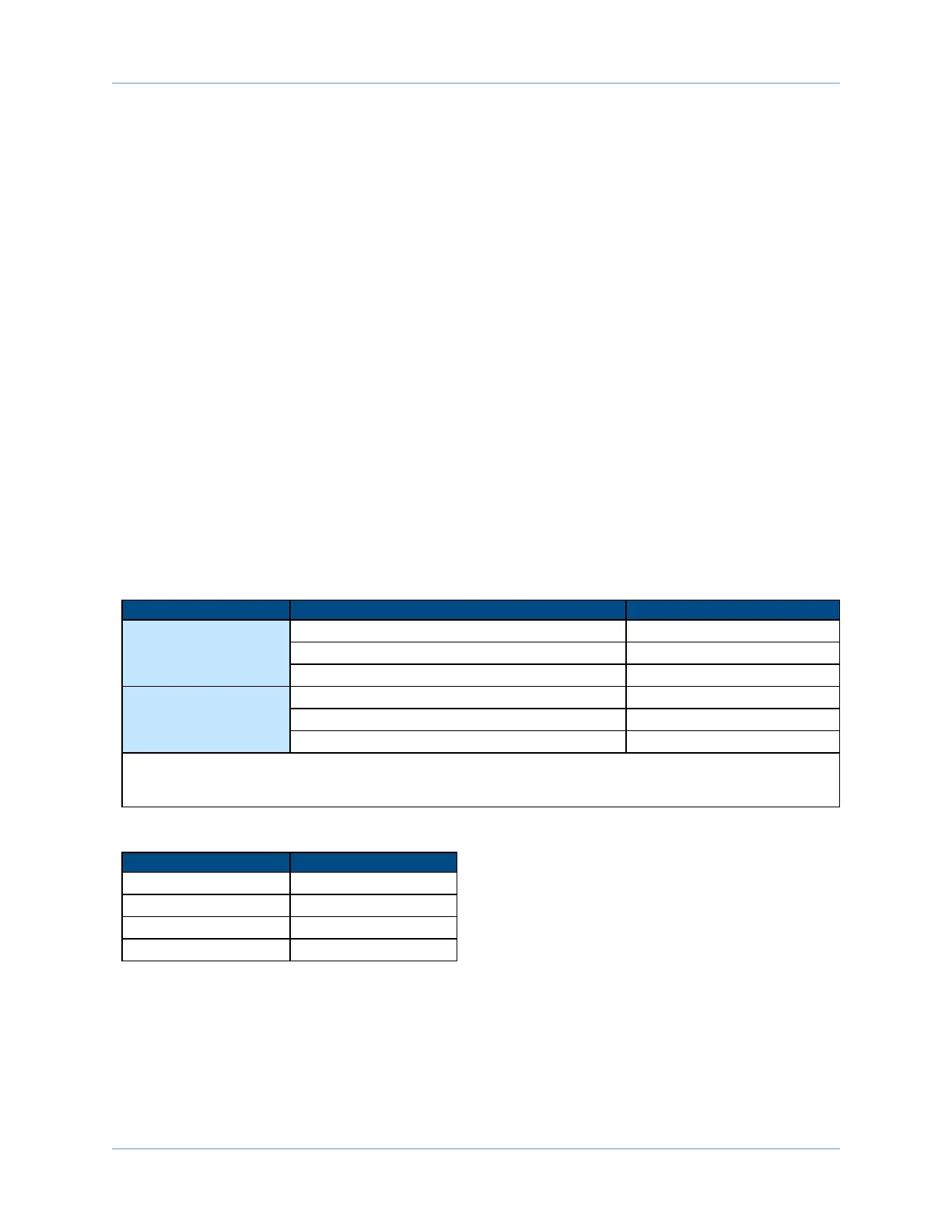

Table 2-3: I/Oand Signal Wiring Specifications

Connection Specification Value

Signal Wiring

Cable/Wire Rating

(1)

300 V

Minimum Current Capacity .25 A

Temperature Rating (Insulation)

(2)

80°C

Low Voltage Power

Cable/Wire Rating

(1)

300 V

Minimum Current Capacity

(3)

1 A

Temperature Rating (Insulation)

(2)

80°C

1. ≥ 30V if the wiring is not in close proximity to wiring operating at voltages above 60 V.

2. Insulation rating will need to be rated for the higher voltage if the wiring is in proximity to wiring operating at voltages above 60 V.

3. Larger gauge wire may be required to minimize voltage drop due to voltage (IR) loss in the cable.

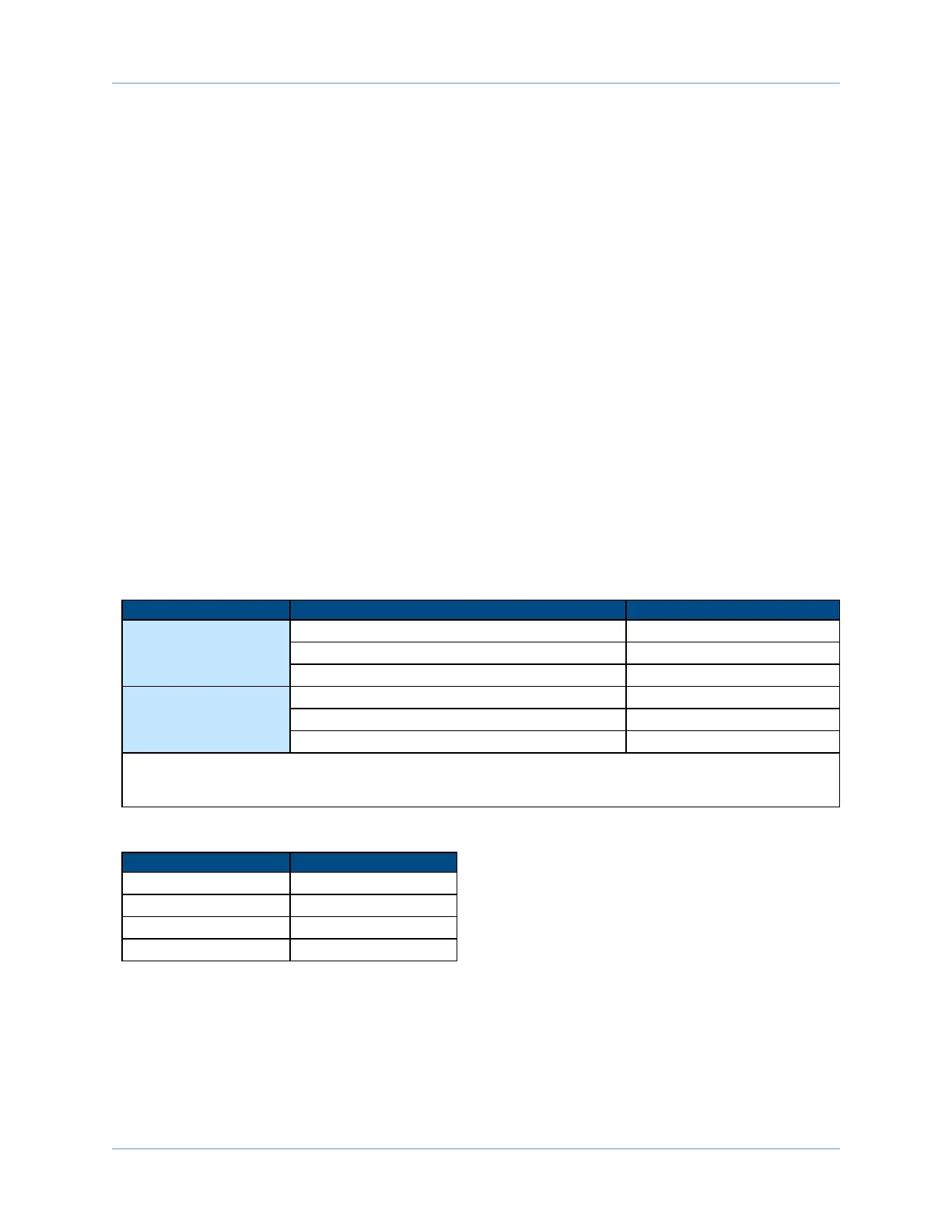

Table 2-4: Recommended Wire Sizes

AWG mm

2

22 .34

24 .25

26 .14

28 .08

14 Chapter 2 www.aerotech.com

Loading...

Loading...