Installation and Configuration HEXRCHardware Manual

2.3.5.2. DC Brush Motor Connections

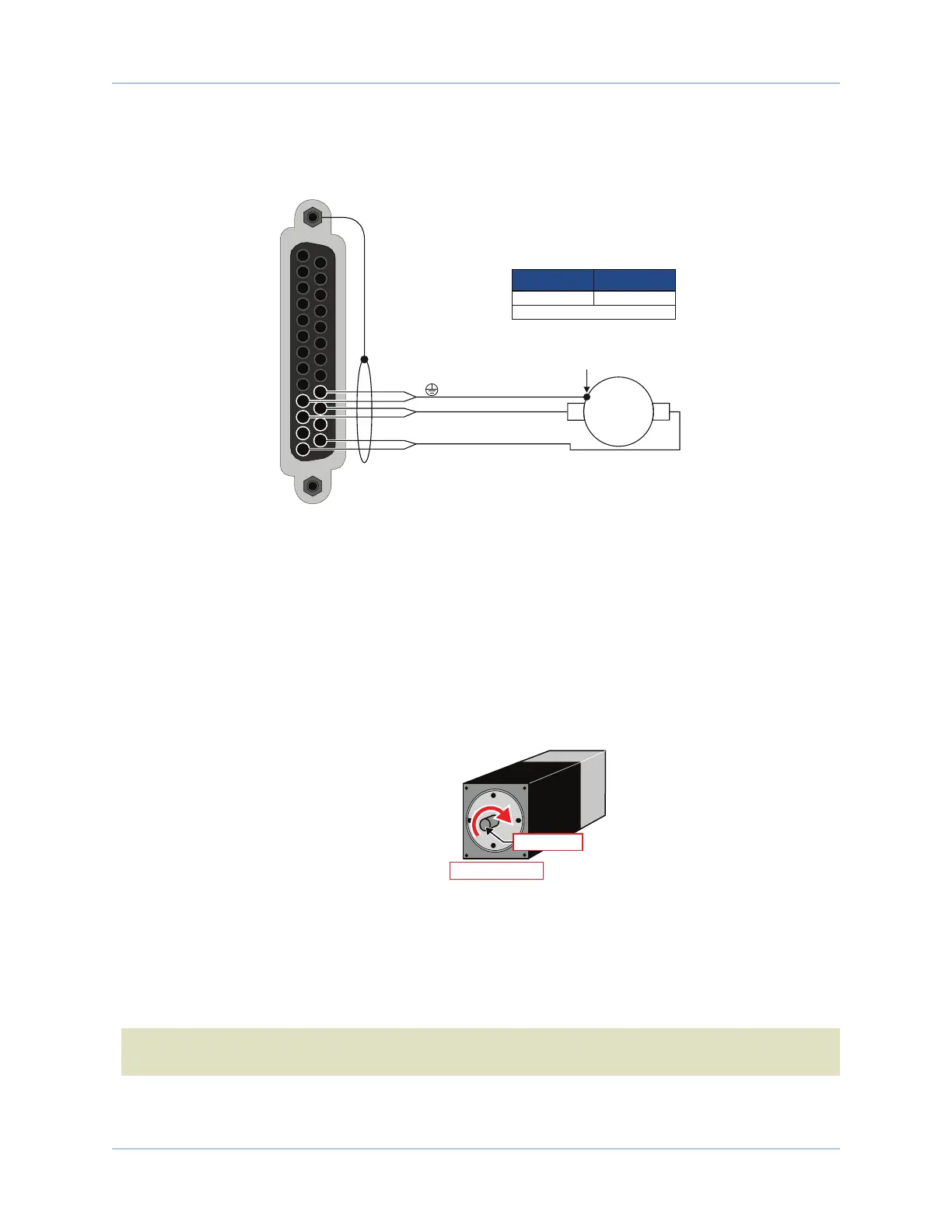

The configuration shown in Figure 2-17 is an example of a typical DC brush motor connection.

[Pins 10, 22]

ØA [Pins 11, 23]

ØC [Pins 13, 25]

13

12

11

10

25

24

23

22

To Backshell

Motor Frame

DC Brush

Motor

+

-

1. Two wires in parralel required.

(1)

22 .34

Recommended Wire Size

AWG mm

2

Figure 2-17: DC Brush Motor Configuration

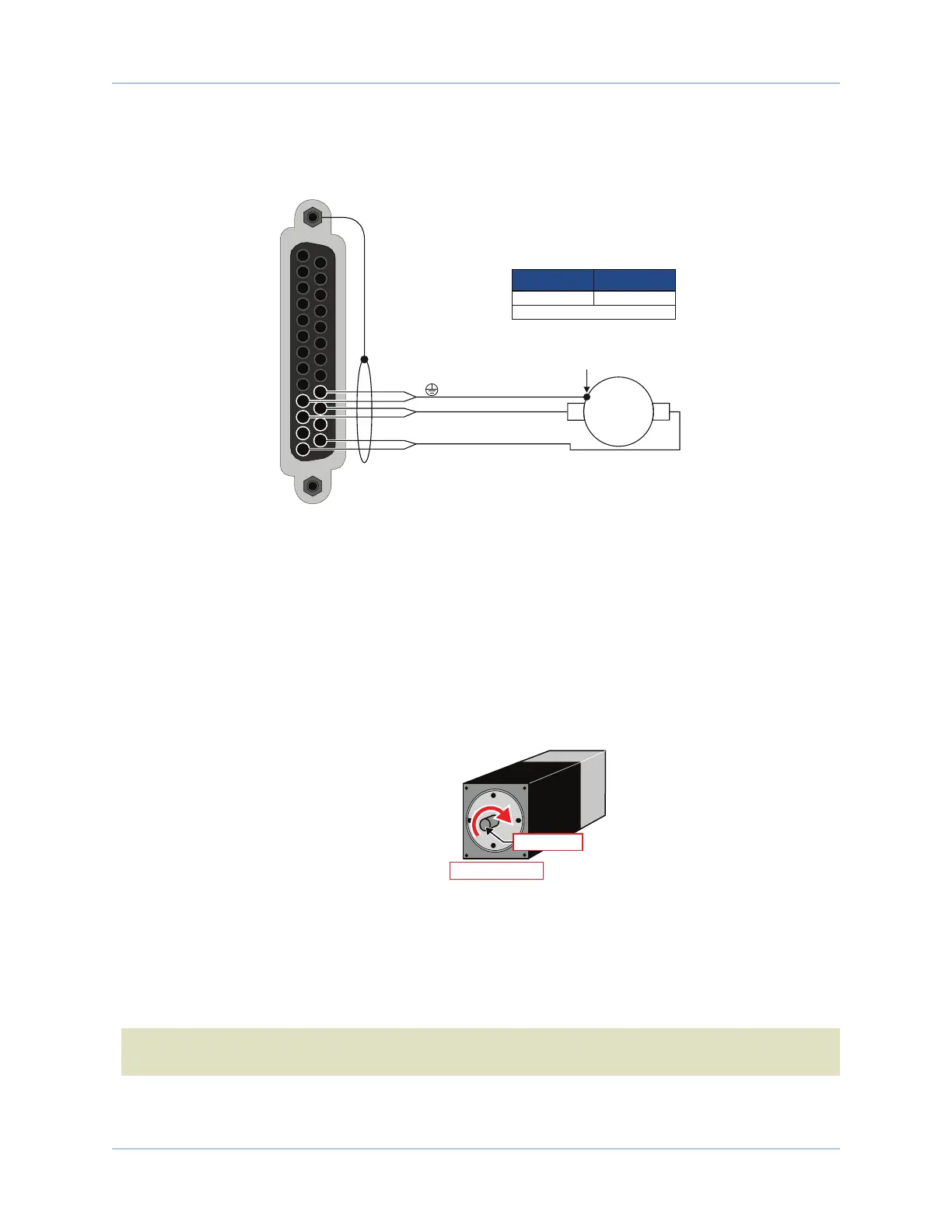

DC Brush Motor Phasing

A properly phased motor means that the positive motor lead should be connected to the ØA motor terminal

and the negative motor lead should be connected to the ØC motor terminal. To determine if the motor is

properly phased, connect a voltmeter to the motor leads of an un-powered motor:

1. Connect the positive lead of the voltmeter to the one of the motor terminals.

2. Connect the negative lead of the voltmeter to the other motor terminal.

3. Rotate the motor clockwise by hand.

Motor Mounting

Flange (Front View)

Motor Shaft

ROTARY MOTOR

POSITIVE MOTION

Figure 2-18: Clockwise Motor Rotation

4. If the voltmeter indicates a negative value, swap the motor leads and rotate the motor (CW, by hand)

again. When the voltmeter indicates a positive value, the motor leads have been identified.

5. Connect the motor lead from the voltmeter to the ØA motor terminal on the HEXRC. Connect the

motor lead from the negative lead of the voltmeter to the ØC motor terminal on the HEXRC.

N O T E : If using standard Aerotech motors and cables, motor and encoder connection adjustments are

not required.

www.aerotech.com Chapter 2 29

Loading...

Loading...