HEXRCHardware Manual Installation and Configuration

2.3.5.3. Stepper Motor Connections

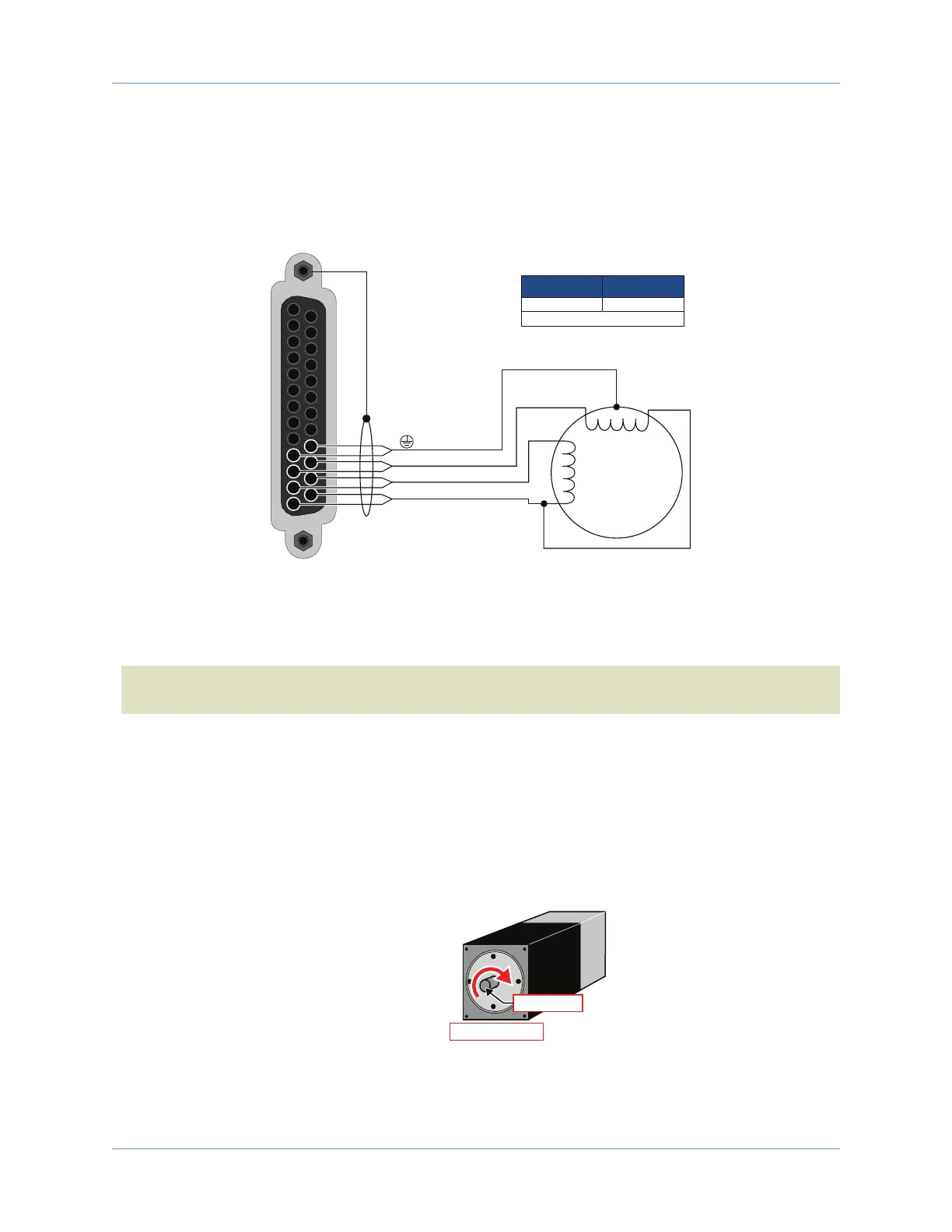

The configuration shown in Figure 2-19 is an example of a typical stepper motor connection.

In this case, the effective motor voltage is half of the applied bus voltage. For example, an 80V motor bus

supply is needed to get 40V across the motor.

13

12

11

10

25

24

23

22

A A’

B’

B

Stepper

Motor

Note the common connection

of A’ and B’ phases.

Motor Frame

To Backshell

[Pins 11, 23]

[Pins 10, 22]

[Pins 12, 24]

[Pins 13, 25]

ØA

ØB

ØC

1. Two wires in parralel required.

(1)

22 .34

Recommended Wire Size

AWG mm

2

Figure 2-19: Stepper Motor Configuration

Stepper Motor Phasing

N O T E : If using standard Aerotech motors and cables, motor and encoder connection adjustments are

not required.

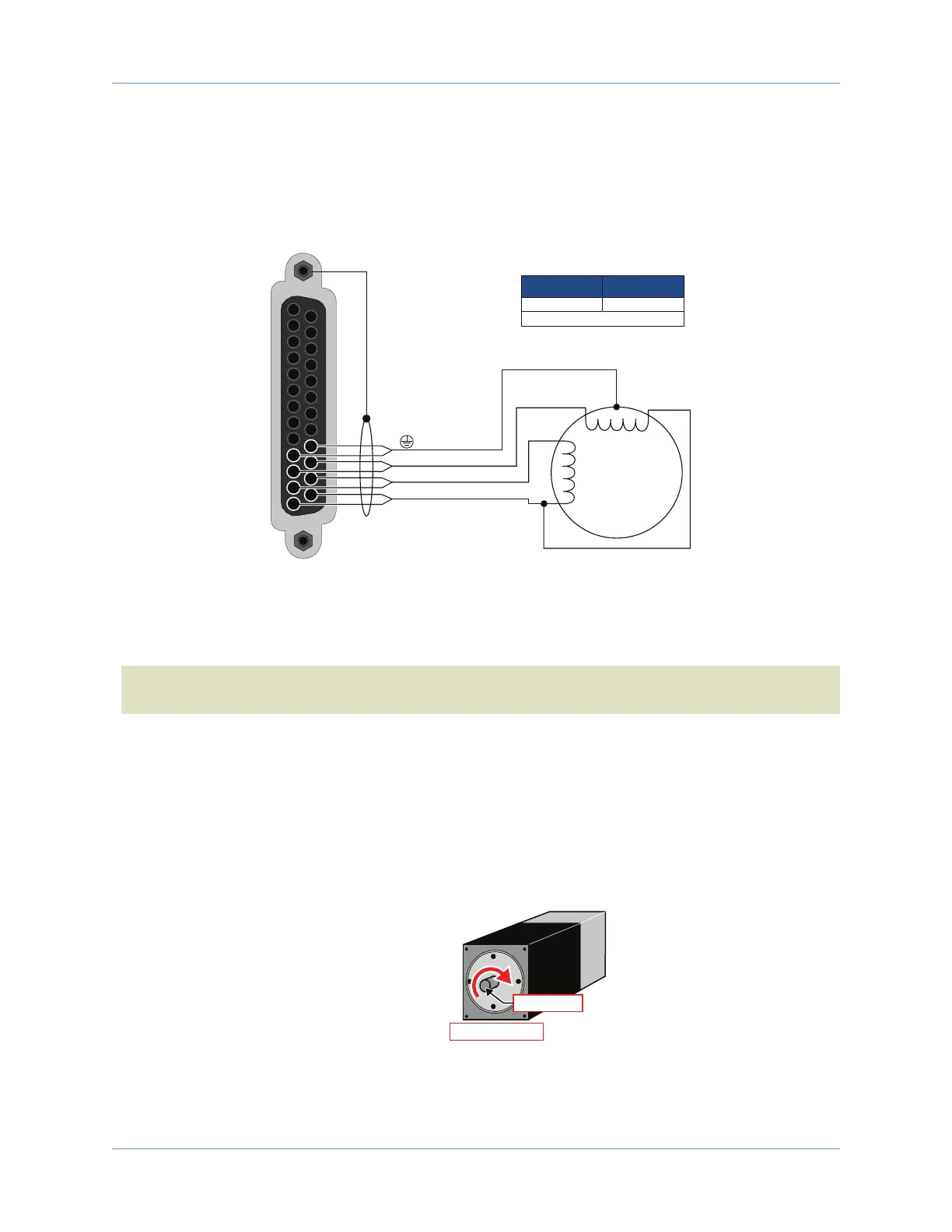

A stepper motor can be run with or without an encoder. If an encoder is not being used, phasing is not

necessary. With an encoder, test for proper motor phasing by running a positive motion command.

If there is a positive scaling factor (determined by the CountsPerUnit parameters) and the motor moves in a

clockwise direction, as viewed looking at the motor from the front mounting flange, the motor is phased

correctly. If the motor moves in a counterclockwise direction, swap the motor leads and re-run the

command.

Proper motor phasing is important because the end of travel (EOT) limit inputs are relative to motor rotation.

Motor Mounting

Flange (Front View)

Motor Shaft

ROTARY MOTOR

POSITIVE MOTION

Figure 2-20: Clockwise Motor Rotation

30 Chapter 2 www.aerotech.com

Loading...

Loading...