Rockwell Automation Publication 1560F-UM001A-EN-P - June 2019 163

Troubleshooting Chapter 9

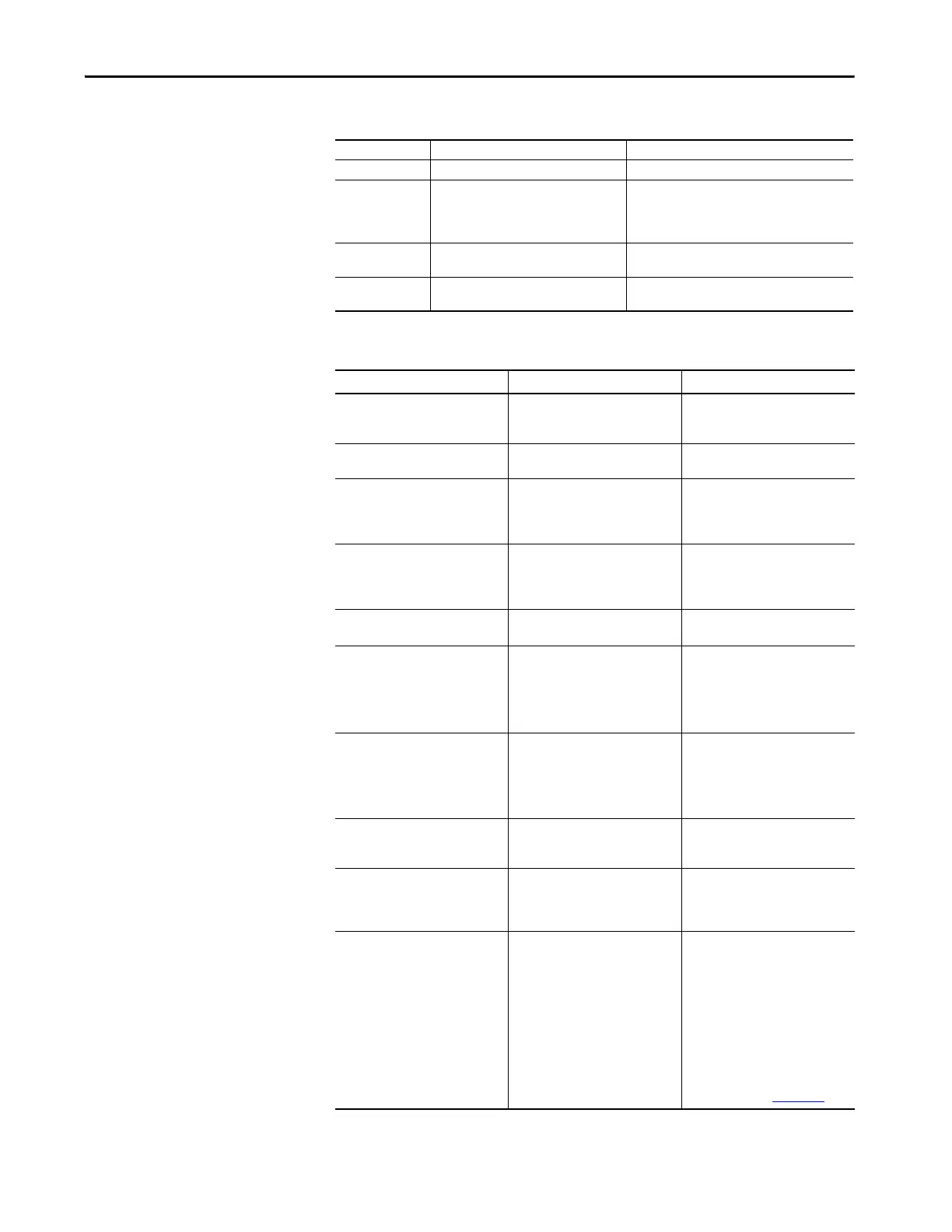

Table 61 - Motor Stops While Running

Display Possible Cause Possible Solutions

Fault displayed • See fault description • See addressing fault conditions

HIM display is blank

•Failed HIM

• Control voltage is absent

• Failed control module

• HIM connection is loose

• Replace HIM

• Check control wiring and correct if necessary

• Replace control module

• Check HIM connection

Stopped

0.0 Amps

•Pilot devices

• Failed control module

• Check control wiring and correct if necessary

• Replace control module

Starting

• One or more power phases are missing

• Failed control module

• Check power system

• Replace control module

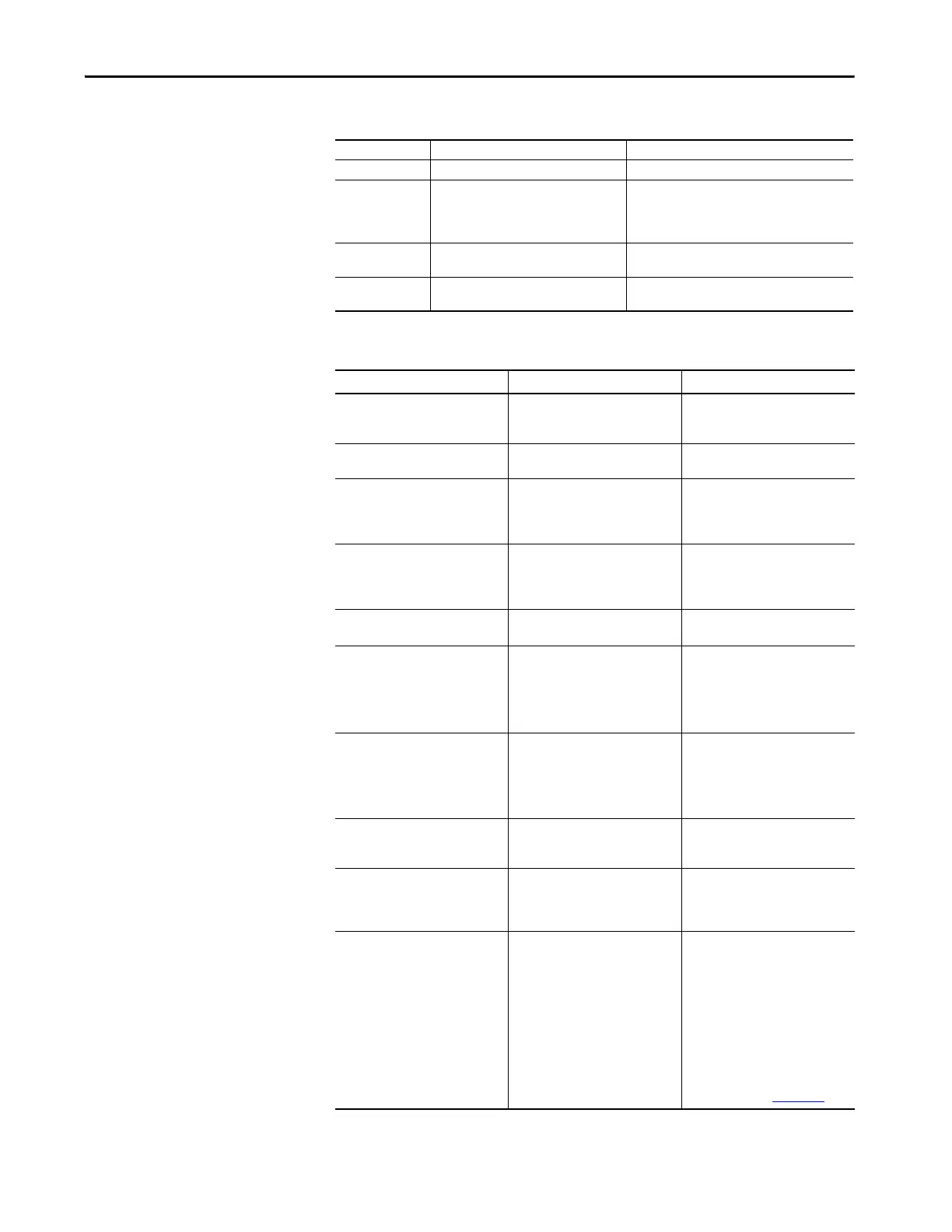

Table 62 - Miscellaneous Situations

Display Possible Causes Possible Solutions

Motor current and voltage fluctuates with

steady load

• Motor

• Erratic Load

• Verity type of motor as a standard

squirrel cage induction motor

• Check load conditions

Erratic operation • Loose connections • Shut off all power to controller and

check for loose connections

Accelerates too fast • Starting time

•Initial torque

• Current limit setting

•Kickstart

• Increase starting time

• Lower initial torque setting

• Decrease current limit setting

• Lower kickstart time or turn off

Accelerates too slow • Starting time

•Initial torque

• Current limit setting

•Kickstart

• Decrease starting time

• Increase initial torque setting

• Increase current limit setting

• Increase kickstart time or turn off

Motor stops too quickly with Soft Stop

option

• Time setting • Verify the programmed stopping time

and correct if necessary

Motor stops too slowly with Soft Stop

option

• Stopping time setting

• Misapplication

• Verify the programmed stopping time

and correct if necessary

• The Soft Stop option is intended to

extend the stopping time for loads that

stop suddenly when power is removed

from the motor.

Fluid surges with pumps still occur with

the Soft Stop option

• Misapplication • Soft Stop ramps voltage down over a set

period of time. In the case of pumps, the

voltage may drop too rapidly to prevent

surges. A closed loop system such as

Pump Control would be more

appropriately suited.

Motor overheats • Overload

• Blocked ventilation

• Allow motor to cool and reduce load.

• Remove blockage and ensure motor is

being adequately cooled.

Motor short circuit • Winding fault • Identify fault and correct

• Check for shorted SCR; replace if

necessary

• Ensure power terminals are secure

Motor coasts when option stop is

programmed

• Option not programmed

• Current loop power supply not active

• Incorrect control logic

• Bypass contactor set for delayed drop-

out

• Verify the option parameter settings

and correct if necessary

• Verify current loop power supply

• Verify connections to module terminals

16 and 17

• Verify that the Bypass Contactor is

configured for <100ms drop-out time.

For relay control, the FDO version

contactor is required; for IntelliVAC

control, set Drop-out time to 50 ms (no

PFCC) or 75 ms (if PFCC contactor in

same controller). For IntelliVAC settings,

refer to Chapter 4 of 1503-UM053

.

Loading...

Loading...