Rockwell Automation Publication 1560F-UM001A-EN-P - June 2019 205

Parameter Information Appendix A

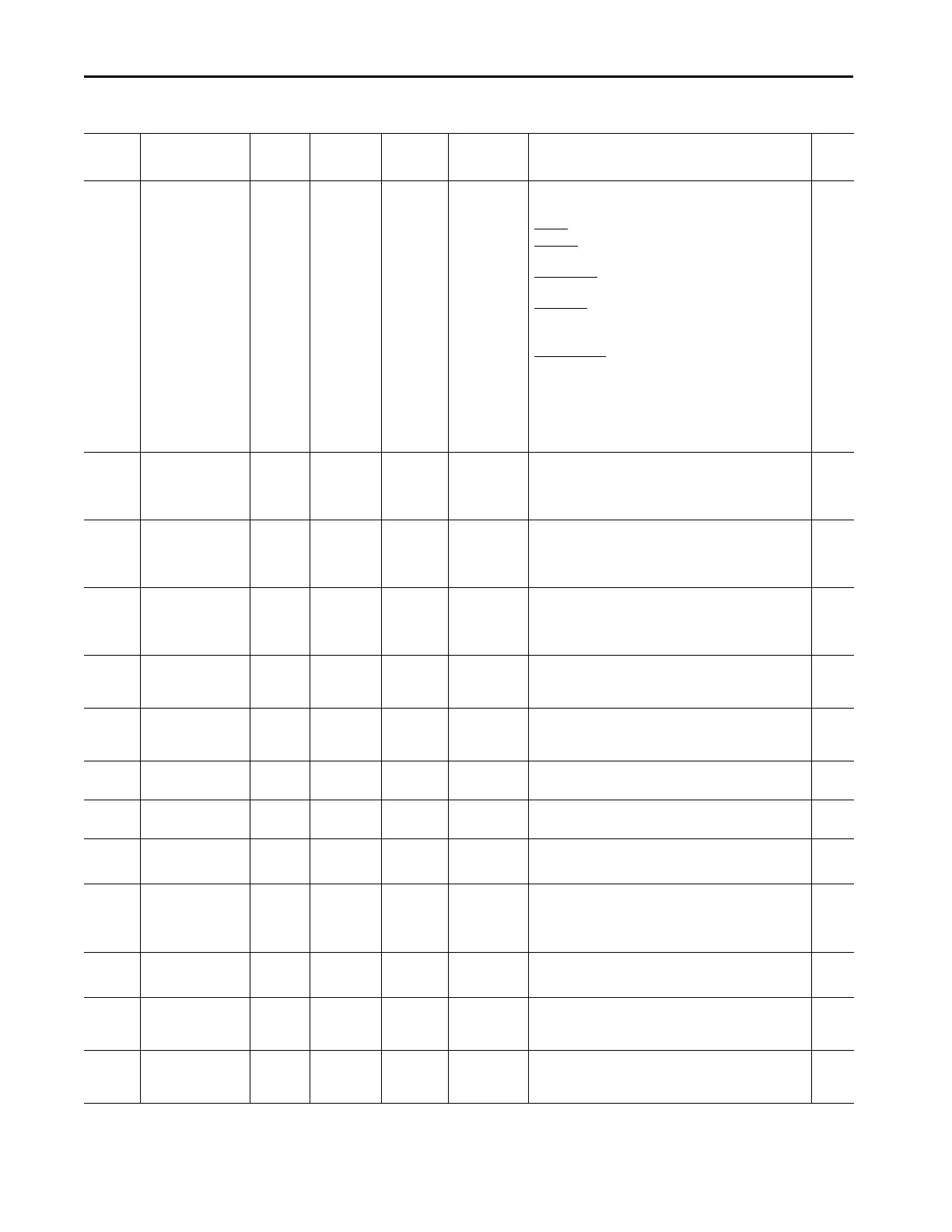

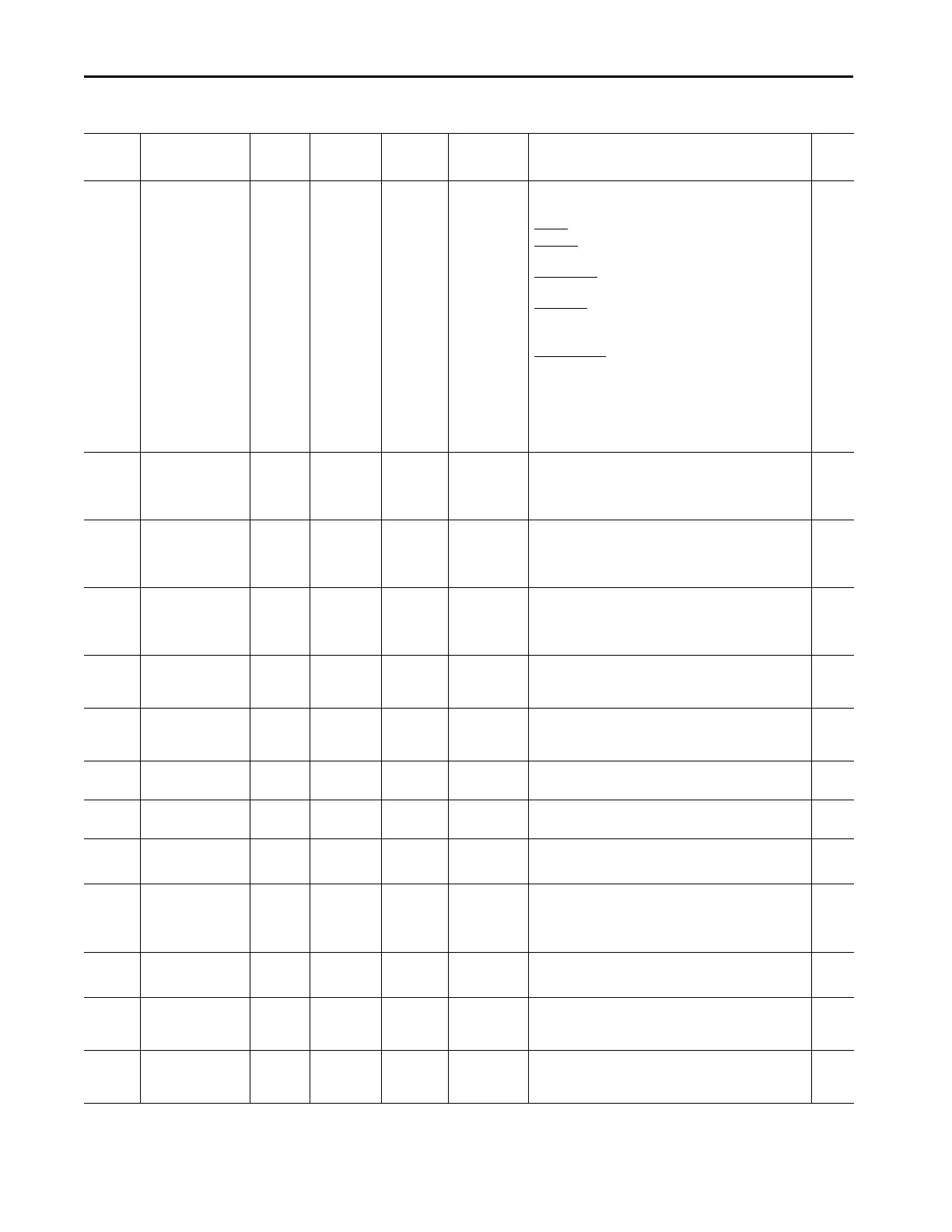

65 Stop Mode 0/5 0 [Coast]

Soft Stop

Linear Speed

Pump Stop

Reserved

External Brake

Allows the user to program the SMC-50 for the type of stopping

that best suits the application.

[Coast]

: Coast-to-Rest.

Soft stop

: Slowly reduces current by reducing voltage applied

to the motor over a programmed period of time.

Linear Speed: Stops the motor following a linear speed ramp

over a programmed period of time.

Pump Stop

: Slowly reduces current by reducing voltage

applied to the motor using the pump

stop algorithm over a programmed period of time.

External Brake: Closes an external contactor to apply braking

current to the motor.

R/W

66 Stop Time Sec 0/999 0 Sets the time period which the controller will ramp the voltage

during a stopping maneuver.

R/W

67 Backspin Timer Sec 0/999 0 Avoids starting into a backspin condition. The timer begins

counting after a stop is completed (coast, stop maneuver, fault

etc). All start inputs will be ignored until the backspin timer has

timed out.

R/W

68 Pump Pedestal % 0/50 0 Provides the ability to adjust the pump algorithm slightly for

different applications. Typically, this is used to shorten the ramp

time before the SMC-50 starts to get aggressive in its pump

stopping maneuver.

R/W

75 Overload Class 5/30 10 Sets the desired trip class of internal solid state overload.

Overload fault and alarms are enabled and disabled in the

Starter Fault En and Starter Alarm parameters.

R/W

76 Overload Class 2 5/30 10 Allows user to set the internal solid state overload to an

alternate trip class. This Trip Class is used when an input

(configured as overload select) is asserted.

R/W

77 Service Factor 0.01/1.99 1.15 Parameter to enter the value of the motor's service factor from

the nameplate.

R/W

78 Motor FLC Amps 1/2200 1.0 Parameter to enter the Full Load Current (FLC) value from the

motor's nameplate.

R/W

79 Motor FLC 2 Amps 1/2200 1.0 Second motor FLC setting to be used when Overload #2 is

selected using the "Overload 2" input.

R/W

80 OL Reset Level %MTU 1/99 75 When the level of Motor Thermal Usage (MTU) drops below this

limit after an OL fault, an overload reset can occur. If restart is

enabled, the motor overload will automatically reset when the

MTU drops below this level.

R/W

81 OL Shunt Time Secs 0/999 0 Disables the overload from incrementing MTU for the selected

time period after a start or stop command is initiated.

R/W

82 OL Inhibit Time Secs 0/999 0 Disables the overload from tripping during stopping

maneuvers. The MTU. Therm Usage continues to increment

during these maneuvers.

R/W

83 Overload A Level %MTU 0/100 90 The MTU level that will set off an alarm when exceeded. The

Overload bit the Motor Alarm En parameter must be set to

signal an alarm.

R/W

Table 66 - SMC -50 Parameter List (Continued)

Number Name Unit Min/Max Default Enum Text Description R/W

Loading...

Loading...