xviii

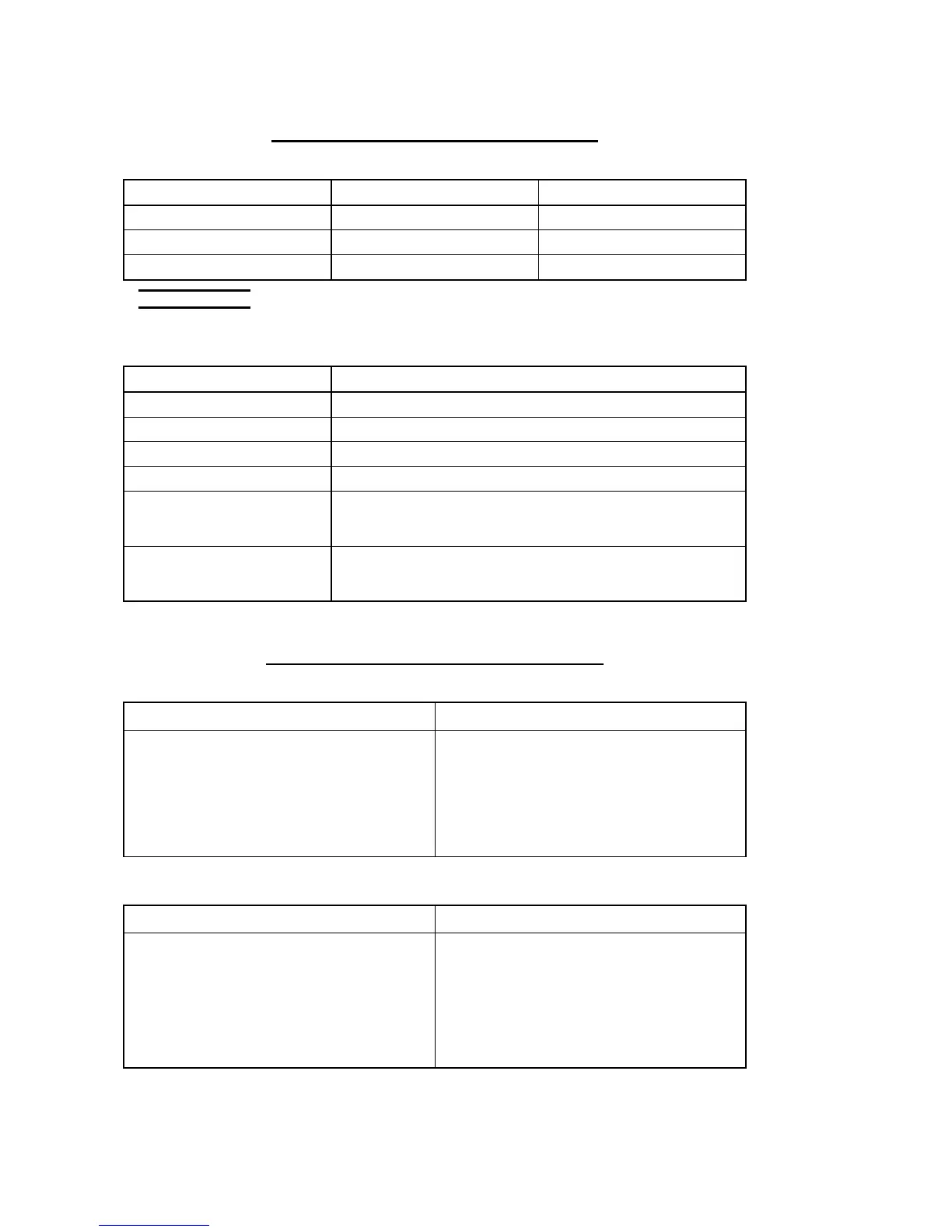

Appendix 1: Classification of cutting fluids

Water-soluble cutting fluids

Color when diluted Main composition

Soluble Milky white or clear Mineral oil

Semi-synthetic Clear Mineral oil

Synthetic Clear Polymer

NOTE

O Dilute each product to the specified ratio.

Oil-based cutting fluids

Main composition

Straight mineral oil Mineral oil

Fatty oil Animal or vegetable oil

Mixed oil Mixture of straight mineral oil and fatty oil

Chlorinated oil Straight mineral oil or mixed oil with addition of chlorine compound

Sulfurized oil

Active: Heavy cutting

Inert: Light cutting

Straight mineral oil or mixed oil with addition of sulfur compound

Sulfochlorinated oil

Active: Heavy cutting

Inert: Light cutting

Straight mineral oil or mixed oil with addition of chlorine and sulfur

compounds

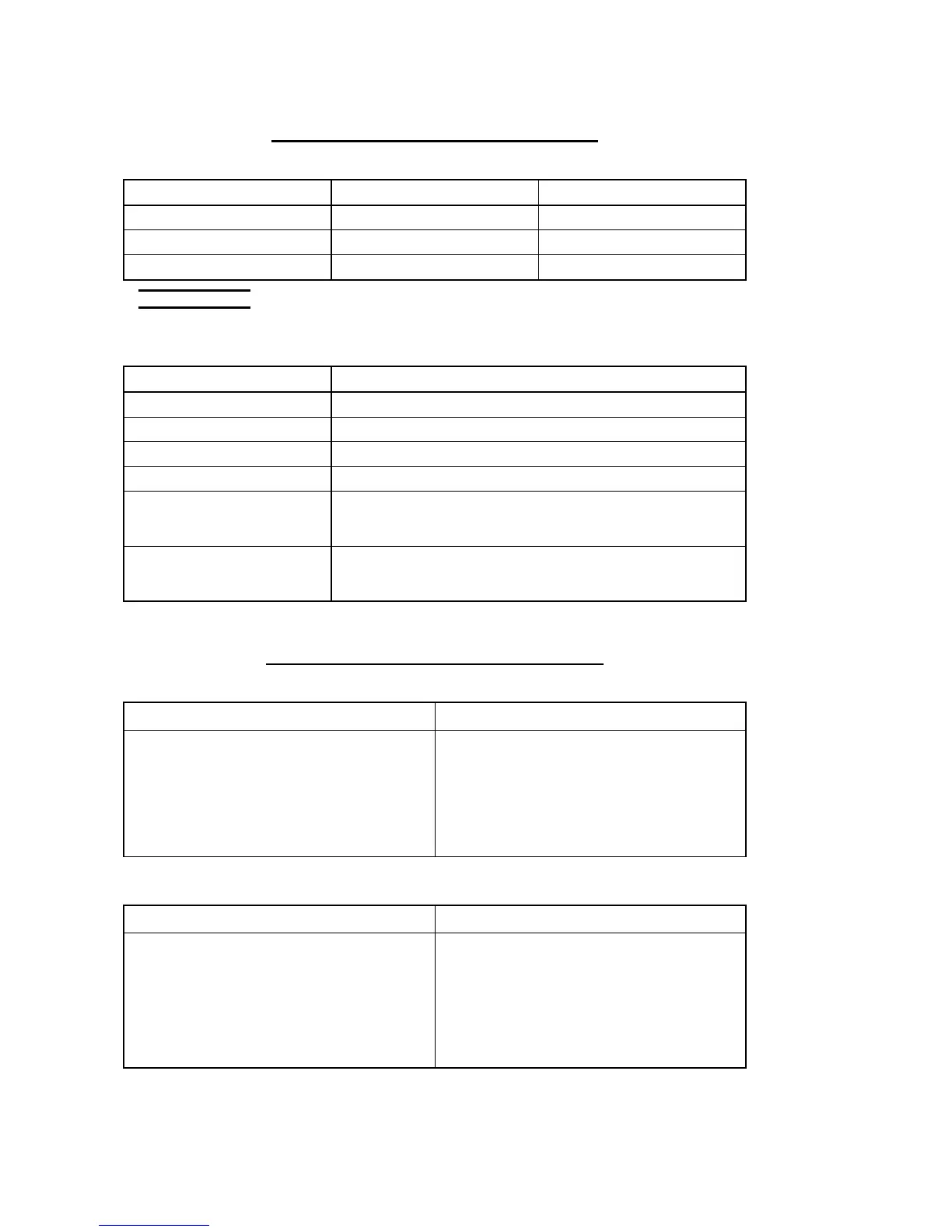

Appendix 2: Characteristics of cutting fluids

Water-soluble cutting fluids

Advantage Disadvantage

• Have high cooling effect

• Not flammable

• Economical

• Do not require cleaning of cut products

(especially when soluble)

• Remove paint

• Lose rust protection effect when deteriorated

• Foam

• Putrefy

• Decline in performance, depending on quality of

water used for dilution

Oil-based cutting fluids

Advantage Disadvantage

• Have high lubricating effect (suited for heavy

cutting)

• Have high cooling effect at elevated

temperatures

• Prevent chip weldment (suited for heavy cutting)

• Provide high corrosion protection for nonferrous

materials (inert type)

• Smoke

• Flammable

• Corrosive to nonferrous materials (active type)

Loading...

Loading...