II-6

LEVELING

Place spirit levels on the front vise bed and rear vise bed (front and rear

vise slide plates), and turn the leveling bolts so that the machine is

leveled front to back and left to right.

NOTE

O Make sure that the leveling

bolts equally carry the

mass of the machine.

LEVELING

BOLT

ANCHOR

BOLT

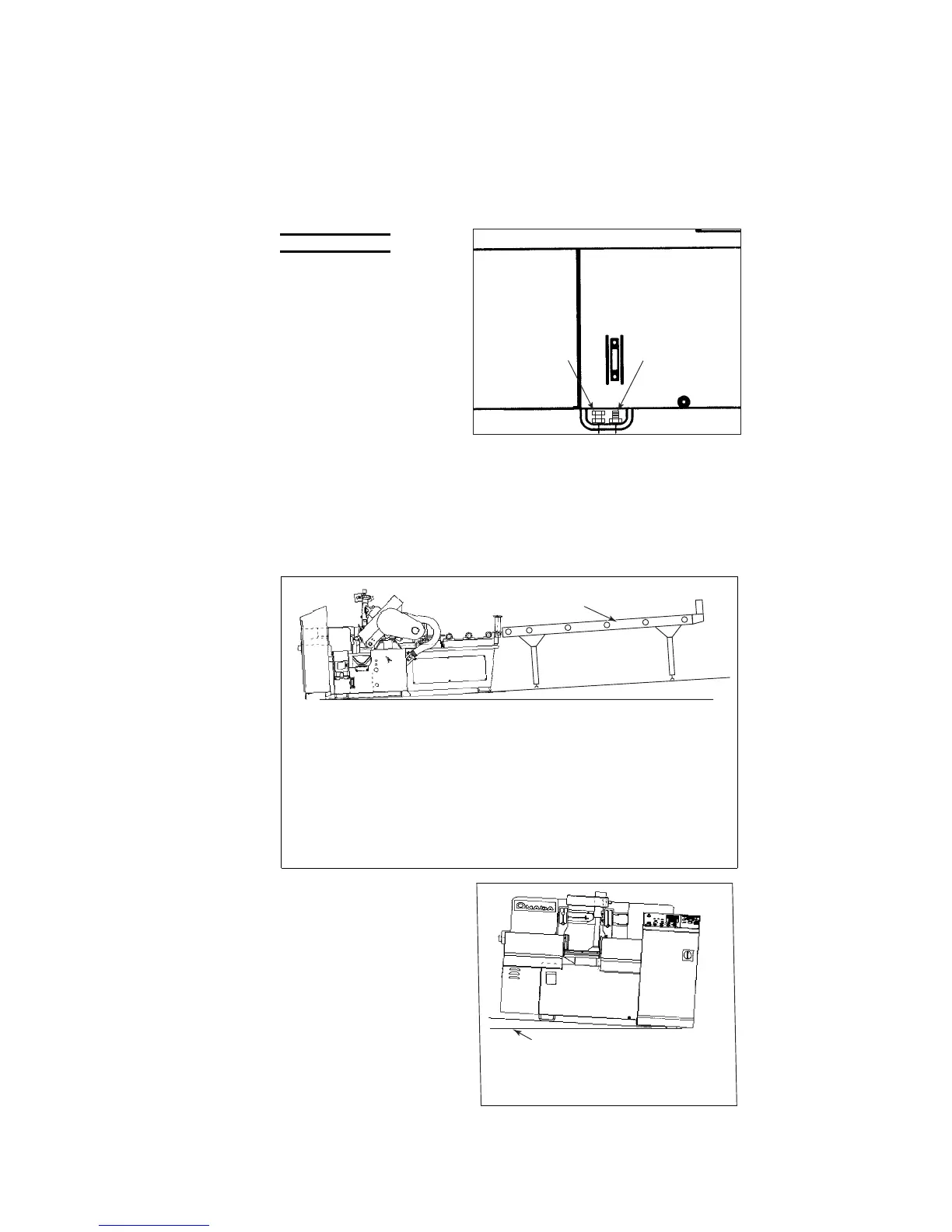

Adjust the machine in the front-to-back direction to about 5/1000 with a

spirit level so that the cutting fluid can return well (see the figure below).

Check with a ruler or the like to see that the front vise bed surface, rear vise

bed surface, work feed roller surface, and optional roller table surface are

flush with each other. Be sure that the roller surface is flush with or higher

by a maximum of 0.12 mm {0.005 in.} than the rear vise table surface.

AB C D E

ROLLER TABLE

(OPTION)

When HFA-250 and HFA-250W machines are adjusted to about 5/1000 in

front-to-back direction with spirit level, surfaces B, C and D become about 4

mm {0.16 in.}, 8 mm {0.31 in.} and 12 mm {0.47 in.} higher than surface A,

respectively.

When HFA-400 and HFA-400W machines are adjusted to about 5/1000 in

front-to-back direction with spirit level, surfaces B, C and D become about 5

mm {0.20 in.}, 11 mm {0.43 in.} and 13 mm {0.51 in.} higher than surface A,

respectively.

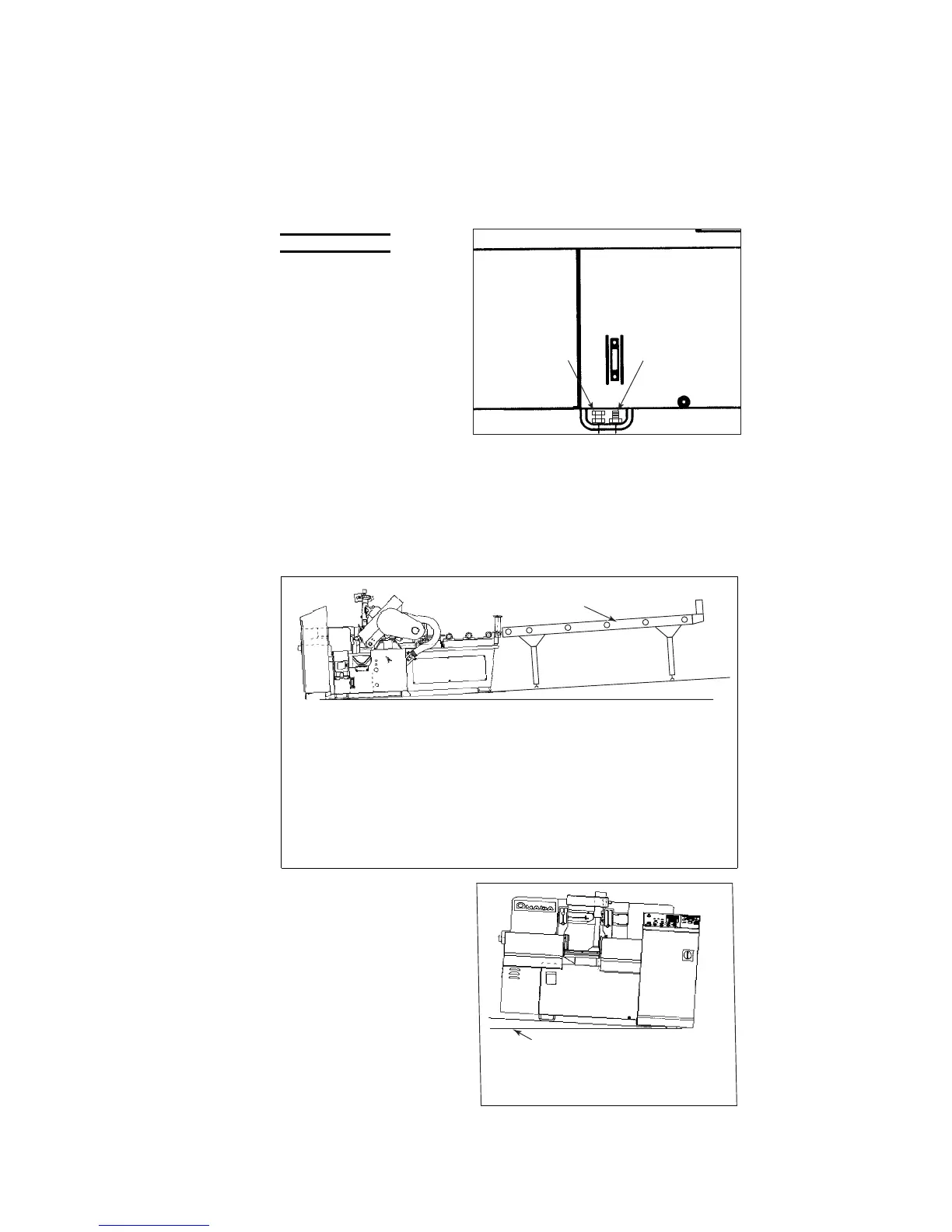

Adjust the machine level or

to about 2/1000 in the left-

to-right direction with

another spirit level. (See

the figure at right.)

If the machine is higher at

the right side than at the

left side, the cutting fluid

will not be recovered well.

Left side of machine becomes

about 3 mm {0.12 in.} higher than

right side when machine is

adjusted to about 2/1000 in left-

to-right direction with spirit level.

Loading...

Loading...