3 | Description Baumer

10 Operating Manual OX100 | V2

3.1.2 Functionality

The sensor measures the surface profile of an object along the projected laser line. Additional

sensor functions (tools) enable geometric measurements on the profile of height, width, or

edge). These measured values are provided at the integrated process interface, the switching

outputs or the analogue output.

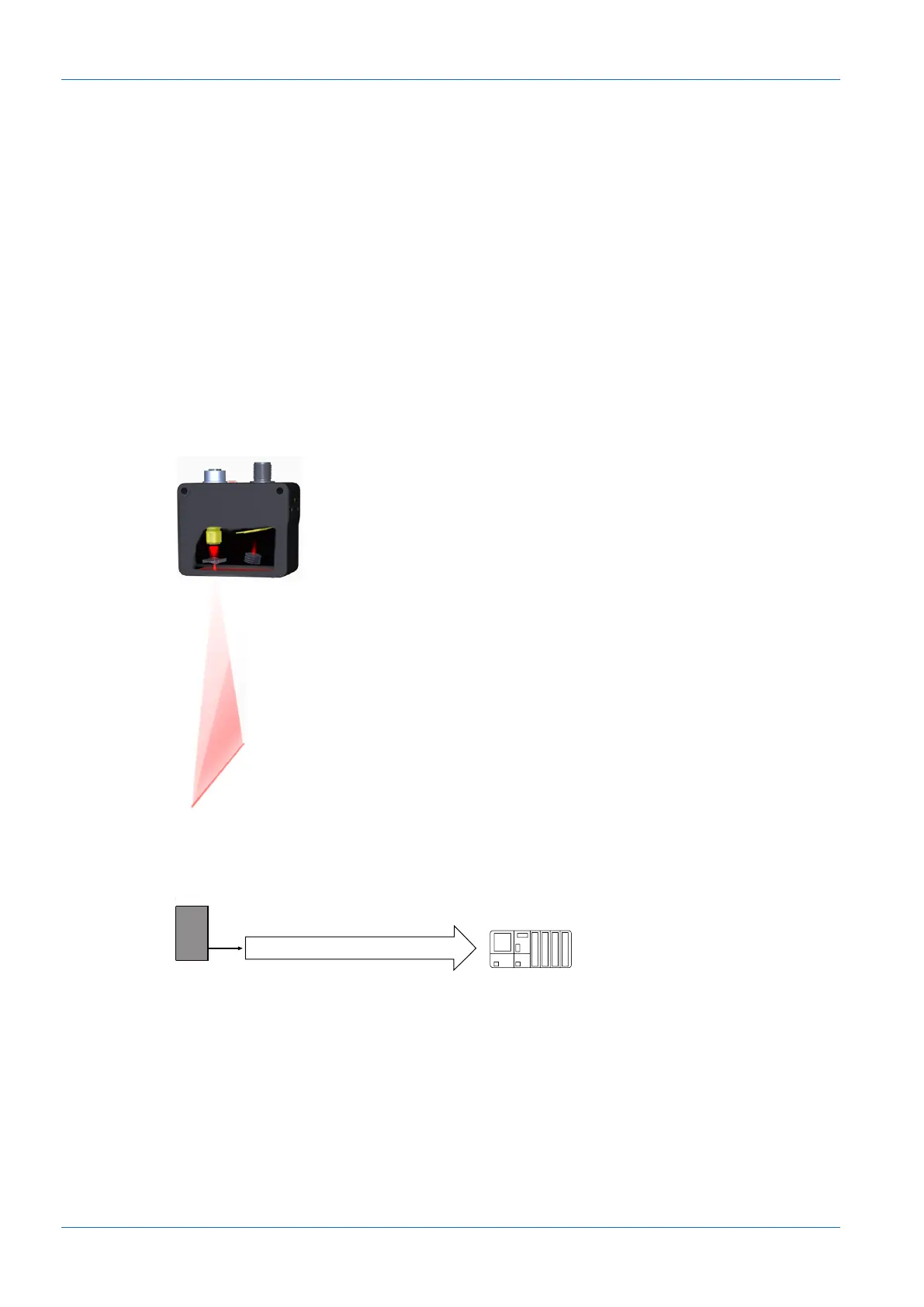

Triangulation principle

The sensor works according to the laser triangulation principle:

1. Via a cylindrical lens, a laser beam is expanded to a laser line and projected onto the sur-

face of the measurement object.

2. The measurement object reflects the laser line.

3. The reflected laser line is projected onto a surface camera in the sensor.

4. The sensor uses the camera image and stored calibration data to calculate the profile of a

measurement object.

Ill.3: Triangulation principle

Sensor functionality

Measurement results

PLCSensor

Ill.4: Functionality

n

The sensor is equipped with smart measurement functions (tools) as well as integrated im-

age processing and delivers precise results in physical units such as mm or degrees.

n

Varied measurement functions, such as edge, width, gap.

n

Correlation of the measured values, e.g. to calculate the difference between to edges.

n

Position tracking of evaluation windows.

Loading...

Loading...