5.1.1 Wrap Quality

Please heed the following tips as not doing so may effect the quality of your wrap:

♦ Make sure to hold the wires tight and straight during wrapping. Kinked or curved wire may cause

spiraling or bubbling.

♦ Make sure to use the correct size label for the wire you intend to wrap.

♦ Do not use wire jackets with greasy coatings or the label will not wrap properly.

♦ Inspect the peel plate area—especially below—to ensure there are no stuck labels.

♦ Clean rollers to ensure that there is no adhesive build-up. See

Cleaning on page 57 of this guide for

cleaning and maintenance recommendations.

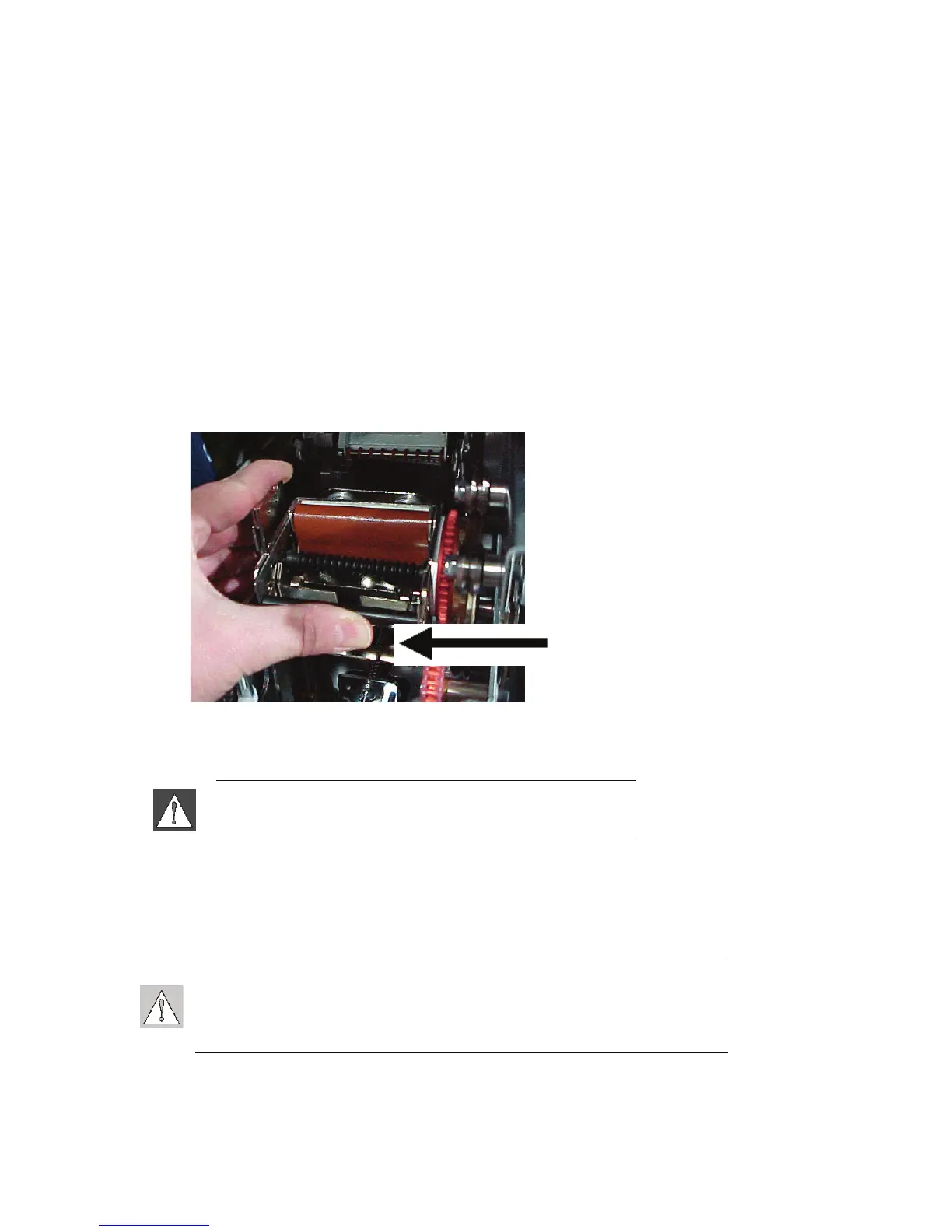

Adjustment for Wire Bundles

You will sometimes (not always) need to adjust the wrapper for wire bundles. This will most likely be

necessary when the bundle contains large wires. To do this:

1. Press the Load Labels button on the Setup tab menu. This shuttles the printer to the “shuttle-back”

position.

2. Power off and unplug the Wraptor.

WARNING: You must power off and unplug the Wraptor

prior to performing any cleaning or maintenance!

3. Open the front (clear) door on the Wraptor.

4. Unscrew the #8-32 socket head cap screw as necessary to retract the roller enough to accommodate the

wire bundle.

5. Close the front door.

6. Wrap the large wire bundles.

CAUTION: You must re-screw the #8-32 socket head cap screw to bring

the roller back out before attempting to wrap other wires. The roller must

be brought back out completely in order run in normal operating mode.

Failure to do so will compromise wrap quality.

Wraptor™ User’s Guide 31

Loading...

Loading...