3-64 2006 Buell Lightning: Engine

HOME

CLEANING AND INSPECTION

11WARNING1WARNING

Compressed air can pierce the skin and flying debris

from compressed air could cause serious eye injury.

Wear safety glasses when working with compressed air.

Never use your hand to check for air leaks or to deter-

mine air flow rates. (00061a)

1. Soak cylinder and piston in an aluminum-compatible

cleaner/solvent until deposits are soft, then clean with a

brush. Blow off loosened carbon and dirt particles and

wash in solvent.

2. Clean oil passage in cylinder with compressed air.

3. Clean piston ring grooves with a piece of compression

ring ground to a chisel shape.

4. Examine piston pin to see that it is not pitted or scored.

5. Check piston pin bushing to see that it is not loose in

connecting rod, grooved, pitted or scored.

a. A piston pin properly fitted to upper connecting rod

bushing has a 0.00125-0.00175 in. (0.03175-

0.04445 mm) clearance in bushing.

b. See Connecting Rod Bushing section. If piston pin-

to-bushing clearance exceeds 0.00200 in. (0.05080

mm), replace worn parts.

6. Clean piston pin retaining ring grooves.

7. Examine piston and cylinder for cracks, burnt spots,

grooves and gouges.

8. Check connecting rod for up and down play in lower

bearings. When up and down play is detected, lower

bearing should be refitted. This requires removing and

disassembling engine crankcase.

Checking Gasket Surface

NOTE

If cylinder gasket surface does not meet flatness specifica-

tions, replace cylinder and piston. Proper tolerances will

extend component life and prevent leaks.

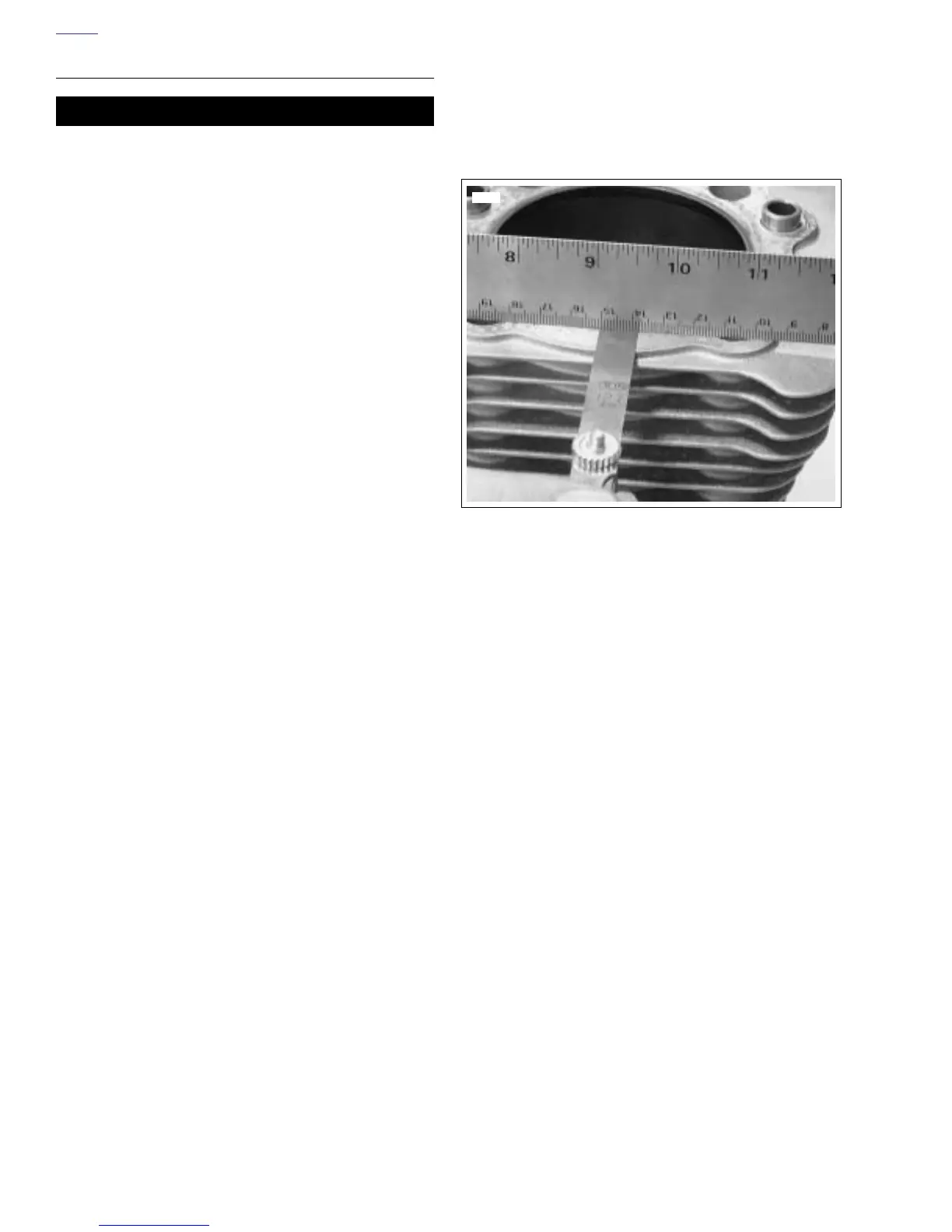

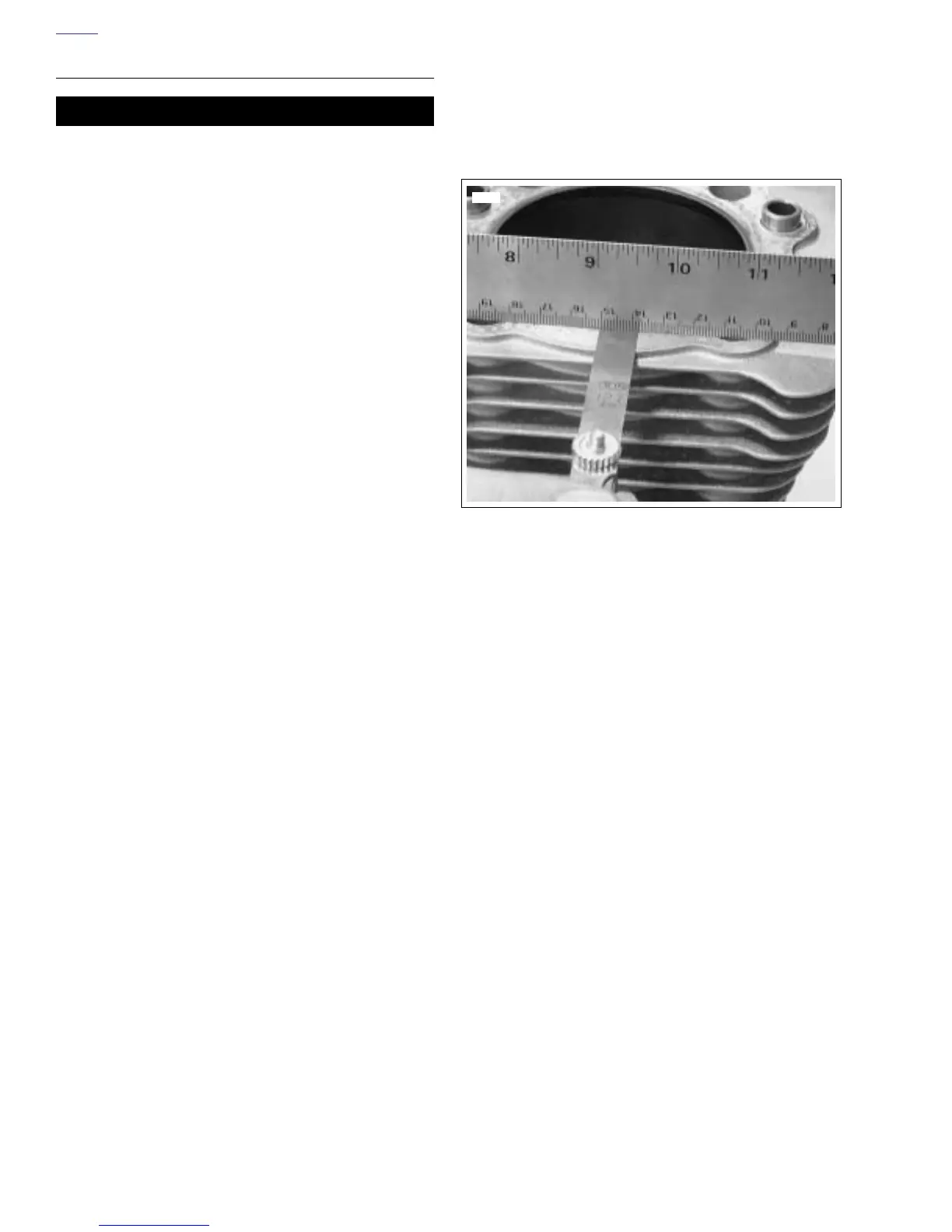

1. See Figure 3-90. Check cylinder head gasket surface for

flatness.

a. Lay a straightedge across the surface.

b. Try to insert a feeler gauge between the straight-

edge and the gasket surface.

c. If cylinder head gasket surface is not flat within

0.006 in. (0.152 mm), replace cylinder and piston.

2. Check cylinder base gasket surface for flatness.

a. Lay a straightedge across the surface.

b. Try to insert a feeler gauge between the straight-

edge and the gasket surface.

c. If cylinder base gasket surface is not flat within

0.008 in. (0.203 mm), replace cylinder and piston.

Figure 3-90. Checking Gasket Surfaces

6611

Loading...

Loading...