Chapter 8

8-11

F-8-14

8.3.8 Determining the Optimum Developing Bias

0006-9613

iR105i/iR105+ / iR9070 / iR85+ / iR8070

An optimum developing bias (Vdc) is computed based on the optimum drum surface potential (VD).

F-8-15

8.3.9 Potential Control for Transparency Mode

0006-9615

iR105i/iR105+ / iR9070 / iR85+ / iR8070

To prevent detachment of toner in high density areas on transparencies, the contrast is decreased to limit the amount of toner deposit. To enable the decrease

in contrast, potential control for transparency mode is executed to select a target value.

WMUPR

WMUP

STBY

195˚C

200˚C

Potential sensor

Developing bias

(DC)

Laser

-10% -20%

Pw Pw1 Pw2 Pw3

Pw8

VL1

VL1 VL2 VL3 VL8

VL-NG

VL-NG

VL2

VL3

Target VL

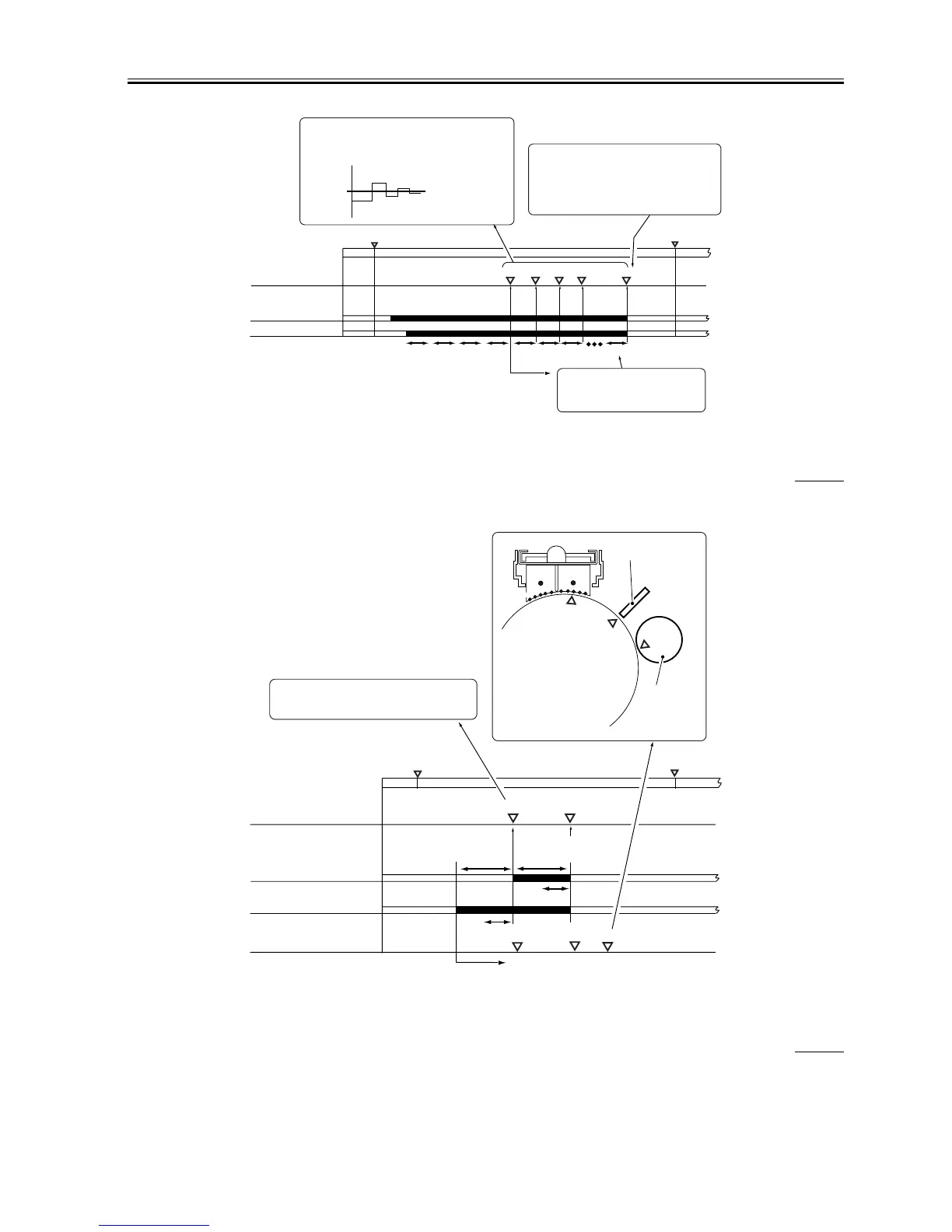

Measurement is continued by varying the

level of the laser output so as to attain

the target VL.

If the measurement is identical to the

target VL, control is ended.

Measurements are taken as many

as 8 times; at times, an approximate

(to the target VL) may be used.

Corrective control sequence

started

The laser output needed to

attain the target VL is

determined.

Reference

output

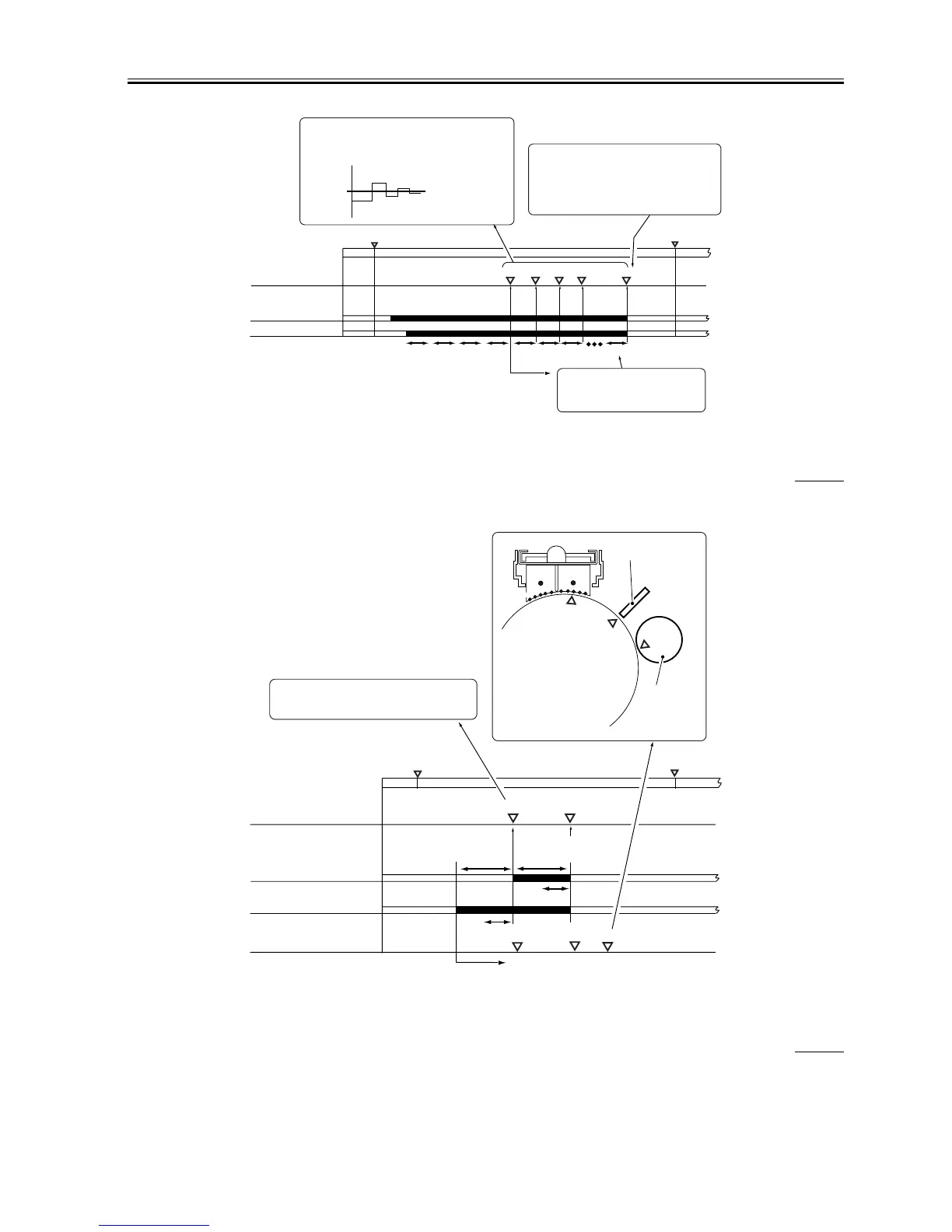

WMUPR

WMUP

STBY

195˚C

200˚C

Potential sensor

Potential determined

Laser

Grid bias

Vg

Vg

Pw

Pw

Potential control sequence started

VD VL

Vdc

Vdc is computed based on this VD;

Vdc = VD - Vback (120 V)

Optimum grid

bias determined

Vg

VD

Vdc

Photosensitive drum

Potential sensor

Developing

cylinder

Optimum laser output

determined

Loading...

Loading...