6-WORKINGOPERATIONS

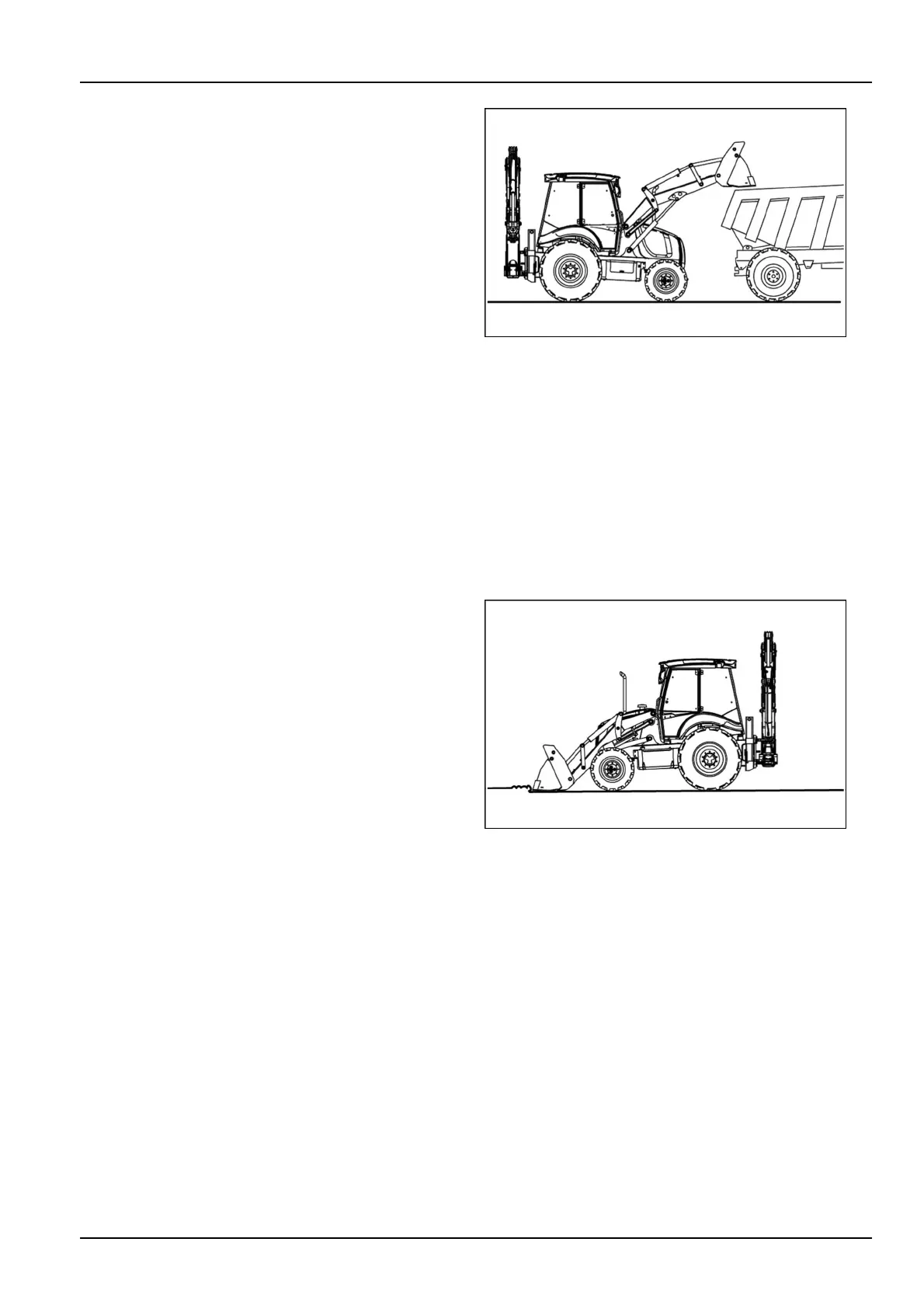

Raisetheloaderhighenoughtoclearanyobstruction

priortodumpingtheload.

Afterthebucketisdumped,backawaywhileloweringand

levelingthebucket,usingthereturn-to-digfeatureifre-

quired.

Duringhardsurfaceoperation,placetheloaderattach-

mentleverin“oat”positionandkeepthebucketlevel.

Thiswillpermitthebucketto“oat”onthecontourofthe

workingsurface.

Ifhydraulicdownpressureisexerted,thebucketwillwear

fasterthannormal.

The“oat”positionwillpreventthemixingofsurfacema-

terialwithstockpilematerial.

Itwillalsoreducethechanceofsurfacegougingwhen

removingsnoworothermaterial.

Whenloadingfromabankselectthehighestforwardgear

whichwillprovidethemostefcientloadingoperation

withoutgoingintoa“stall”.

Keeptheworkingareafreeofrutsandholesoccasionally

backgradingwiththebucketusingthelowrearedgeof

thebucket.

LEEN11T0155AA4

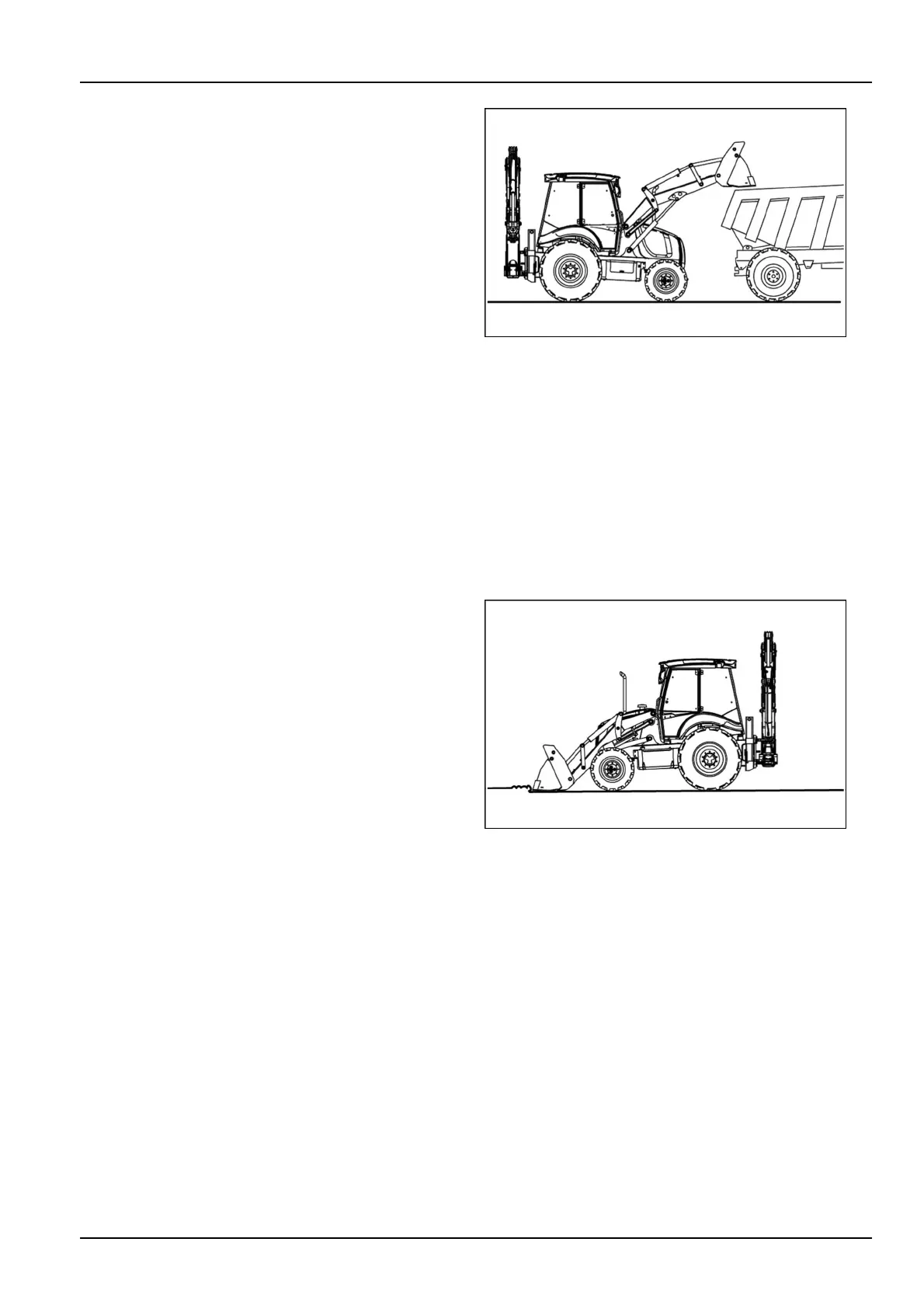

Forsitestrippingpeelingorscraping,usedownpressure

withtheloaderattachmentleverintheloweredposition,

andaslightbucketangletostartthecut.Beginthecutat

thenotchapproximately50m(1.96in)deepandholdthe

depthbyfeatheringthebuckettoadjustthecuttinglipup

ordownasrequired.

Whenthemachinefronttiresenterthecut,adjustthelift

armstomaintainthecorrectdepth.

Makeadditionalcutsuntilthedesireddepthisreached.

Backgradetheworkingareaoccasionallywiththebucket

atandslightdownpressuretokeeptheworkingarea

smoothandfreefromrutsorholes.

Iftheloaderattachmentleverismovedforliftcylinderac-

tionwithoutcontrollingthebucketangle,thebucketmay

gougeandleaveaseriesofrutsinthesurface.

LEEN11T0156AA5

6-9

Loading...

Loading...