7-MAINTENANCE

Loaderbucket-self-levelingadjustment(Bentarm)

Modelswithoutstraightloaderarm

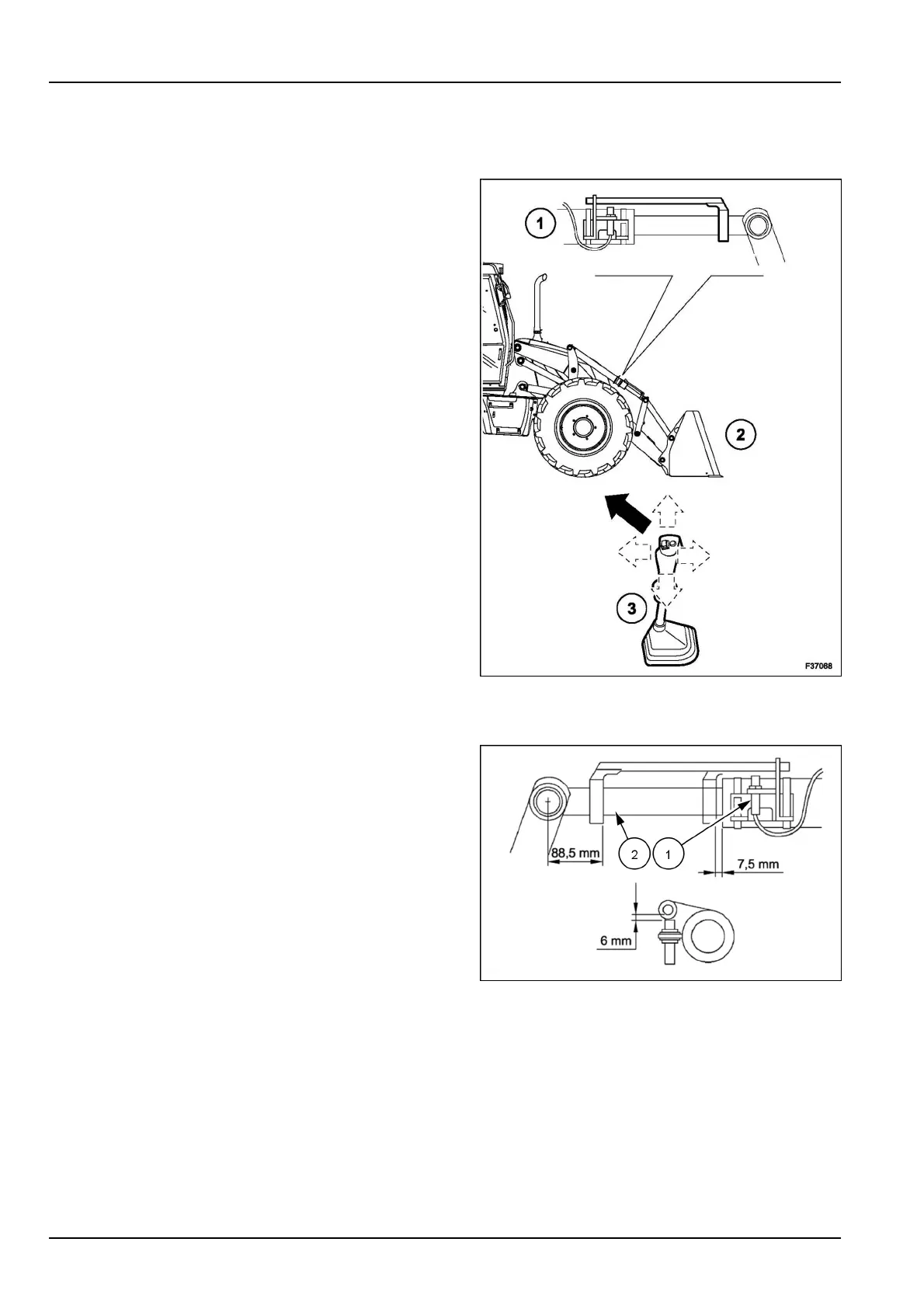

The“return-to-dig”deviceisanelectricallyactivated

featurewhichenablestheoperatortoautomatically

returnthebuckettoaleveldiggingpositionforafurther

workcycle,withonesimplemovementofthecontrol

lever(3).

Wheneverthebucketisrolledforwardtodumpthere-

turn-to-digelectriccircuitiscompletedandthesolenoid

onthebucketspoolisenergized.

Whentheloaderbucketcontrollever(3)ismoveddi-

agonallylefttothereturn-to-digposition(2)theelectro-

magnetwillholdthebucketspoolintherollbackpo-

sitionuntilthebucketisintheleveldiggingpositionat

whichtimetheindicatorontherodofthebucketlinkage

willpassinfrontofthesensorwhichde-energizesthe

electromagnetonthebucketspoolenablingthespool

toreturntotheneutralposition.

LEEN12T0585AA1

Return-to-digsensor-adjustment

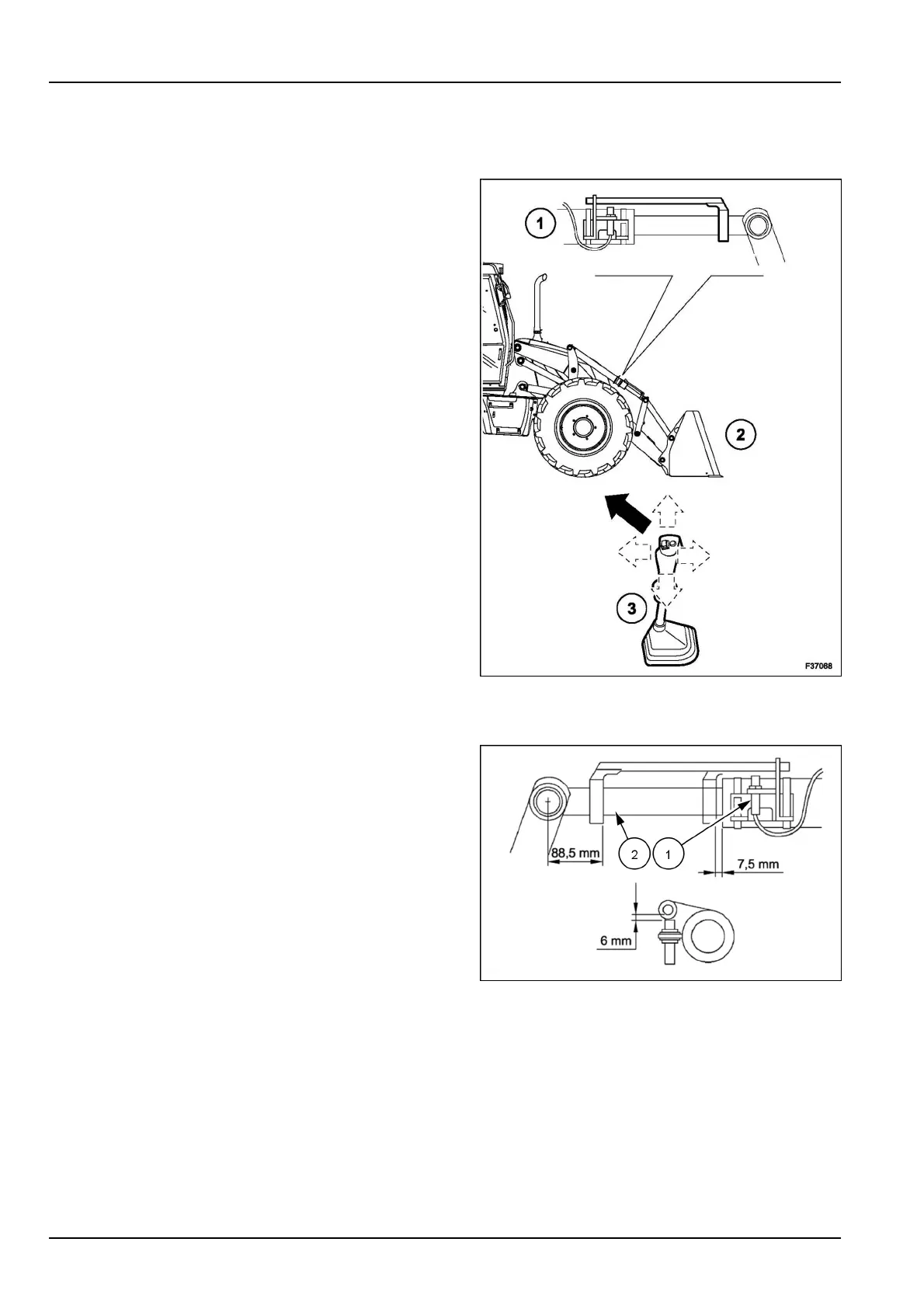

1.Thereturn-to-digsystemconsistsofanelectromagnet

mountedontheloaderbucketcontrolvalvespool,a

sensor(1)mountedontopoftheloaderarmanda

pointerattachedtothetubeofthebucketself-levelling

linkage.

2.Placethebucketonthegroundinthepreferreddigging

position.

3.Checkthedimensionsof88.5mm(3.48in)and

7.5mm(0.29in)aremaintainedasshown.

4.Ensurethatthefaceofthesensor(1)is6mm(0.23in)

fromtherod(2).

LEEN12T0511AA2

NOTE:Asavisualaidfortheoperator,whileseatedinthecab,thepointermountedontheloaderarmcanbeseen

toalignwiththepointeronthereturn-to-diglinkage,whentheloaderarmsareloweredandthebucketisinthelevel

diggingposition.

7-138

Loading...

Loading...