7-MAINTENANCE

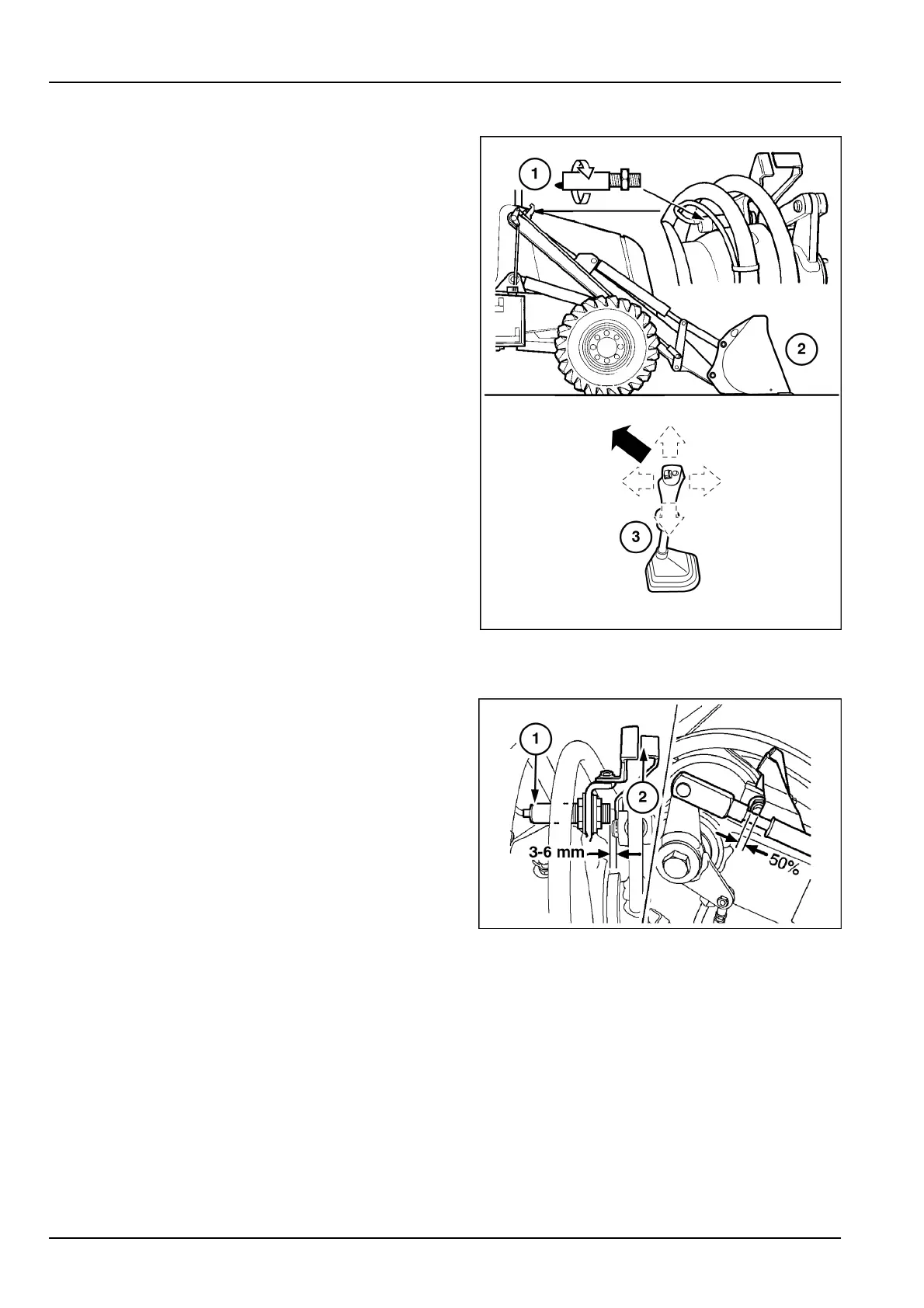

“Return-to-dig”system-2WS

Returntodigisanelectricallyactivatedfeaturewhich

enablestheoperatortoautomaticallyreturnthebucket

toaleveldiggingpositionforafurtherworkcyclewith

onesimplemovementoftheloadercontrollever(3).

Wheneverthebucketisrolledforwardtodumpthere-

turn-to-digelectricalcircuitiscompletedandthesole-

noidonthebucketspoolisenergized.

Whentheloaderbucketcontrollever(3)ismoveddi-

agonallylefttothereturn-to-digposition(2)theelectro-

magnetwillholdthebucketspoolintherollbackpo-

sitionuntilthebucketisintheleveldiggingpositionat

whichtimetheindicatorontherodofthebucketself-

levellinglinkagewillpassinfrontofthesensorwhich

de-energizestheelectromagnetonthebucketspoolen-

ablingthespooltoreturntotheneutralposition.

MOLI12LBB0503BB4

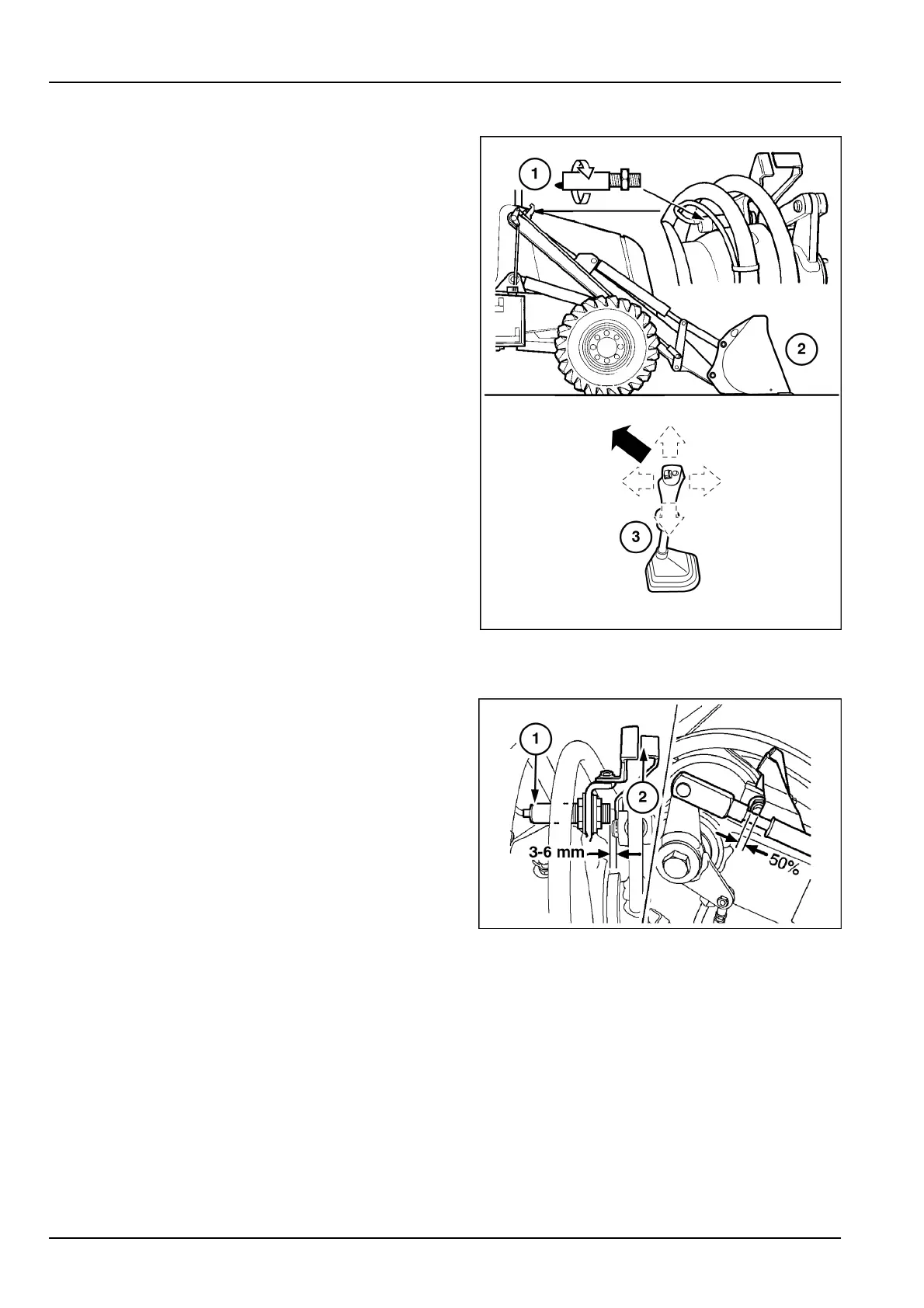

Return-to-digsensor-adjustment

1.Thereturntodigsystemconsistsofanelectromagnet

mountedonthebucketspool,asensor(1)mountedon

topoftheloaderarmandapointerattachedtothetube

ofthebucketself-levellinglinkage.

2.Placethebucketonthegroundinthepreferreddigging

position.

3.Adjustthepositionofthesensorsuchthatwhenthe

bucketisindiggingpositionandloaderarmsarelow-

ered,half(50%)ofthesensorfaceisobscuredbythe

self-levellinglinkagepointer.

4.Ensurethatthefaceofthesensor(1)is3-6mm(0.12

-0.24in)fromthepointer(2)ontheself-levellinglink-

age.

MOLI12LBB0504AB5

NOTE:Asavisualaidfortheoperator,whileseatedinthecab,thepointermountedontheloaderarmcanbeseen

toalignwiththepointerontheself-levellinglinkage,whentheloaderarmsareloweredandthebucketisinthelevel

diggingposition.

7-136

Loading...

Loading...