36

– Steamhosesmustbepreventedfromsagging(condensatepockets);ifnecessary,supportwith

pipeclamps,trough,orwallbrackets,orinstallacondensatedraininthesteamhose.

– Important!Whendecidingonthelengthandlayoutofthehose,itshouldbenotedthatthesteam

hose may become somewhat shorter with progressive ageing.

Securing the hose

Thesteamhosemustbesecuredtothesteamdistributionpipeandhumidiersteamoutletbymeans

ofhose clamps.

Caution!Donotovertightenthehoseclamponthesteamconnectorofthesteamhumidier.

Steamlinewithxedpiping

Forsteamlineswithxedpiping,thesameinstructionsapplytothelayingofthepipingasalready

described.Thefollowingadditionalnotesshouldbeobserved:

– The minimum internal diameter of 22 mm, 30 mm or 45 mm respectively should be applied

overthewholelengthofthepiping.

– UseexclusivelyCupipeorstainlesssteel(min.DIN1.4301).

– Tominimizethecondensateformation(=loss),thesteampipesmustbeinsulated.

– The minimum bend radiusforsolidpipesis4-5 x internal diameter.

– Connectionofthesteampipetothesteamdistributionpipeandtothesteamhumidieriseffected

bymeansofshortlengthsofsteamhosesecuredwithhoseclamps.

– Important! Allowancemustbemadeforapressure loss of 10 mm water column (approx.

100 Pa)permeterlengthorper90°bend.

5.3.6 Installing the condensate hose

Important! Use original Condair condensate hose exclusively. Other types ofhoses can cause

operationalmalfunctions.

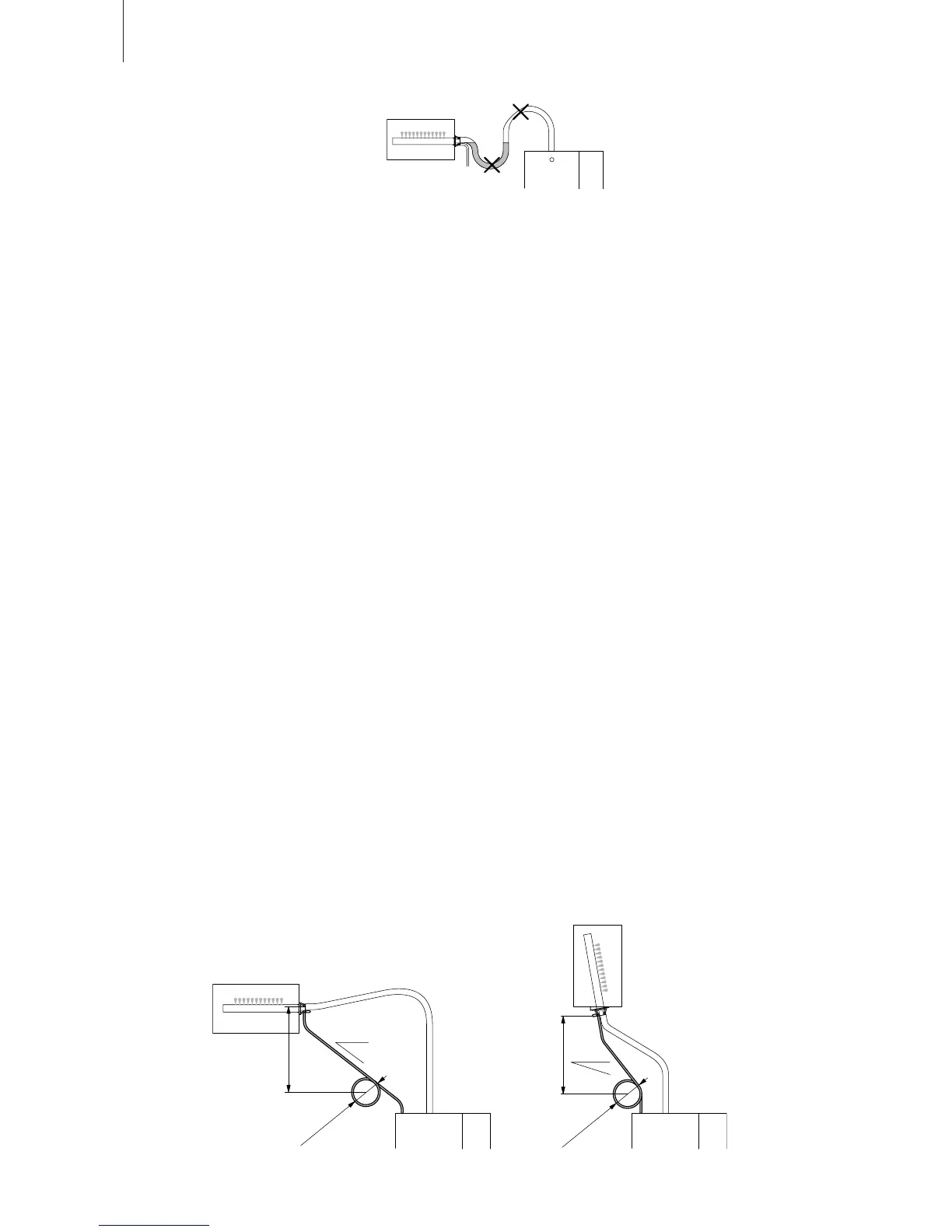

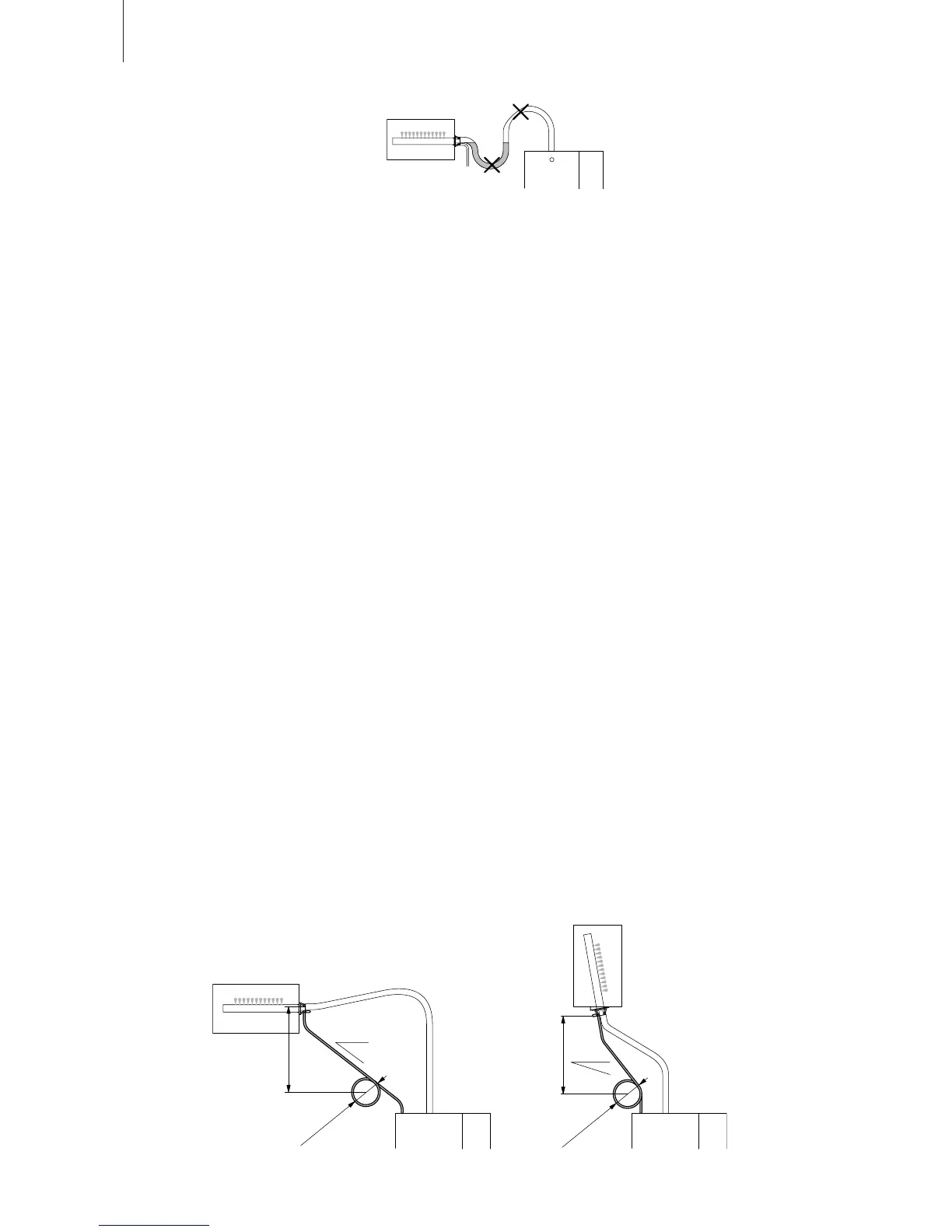

Thehoselayoutdependsonthepositionofthesteamdistributionpipe:

– Steam distribution pipe is mounted morethan300mmabovethetopedgeofthehumidier:

Condensatehoseisleddowntothehumidierwithaminimum slope of 20 %,intheformofa

siphon (min. hose bend diameter Ø200 mm ),andinsertedabout2cmintothespeciedopening.

min. 300 mm

min. 20 %

Ømin. 200 mm

min. 300 mm

min. 20 %

Ømin. 200 mm

Loading...

Loading...