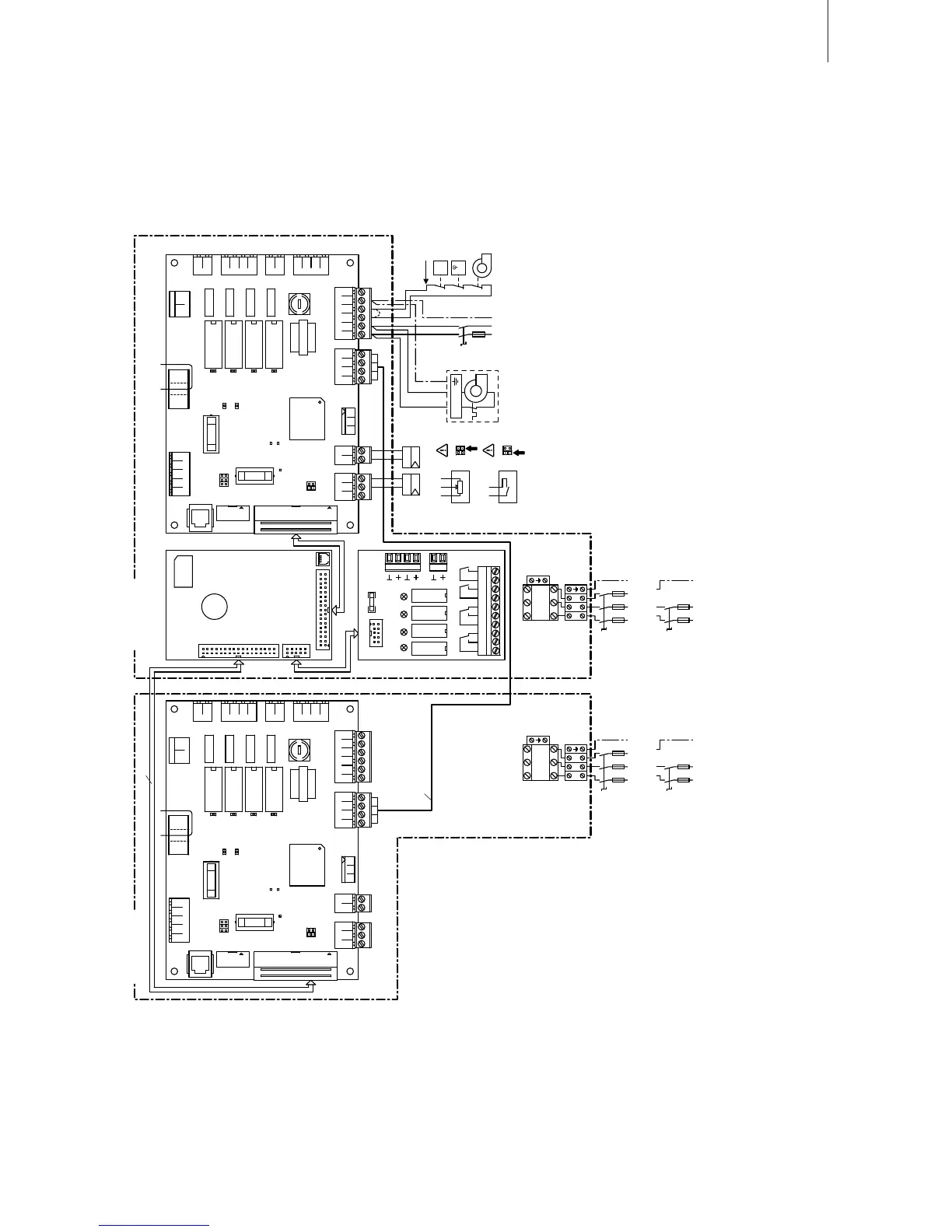

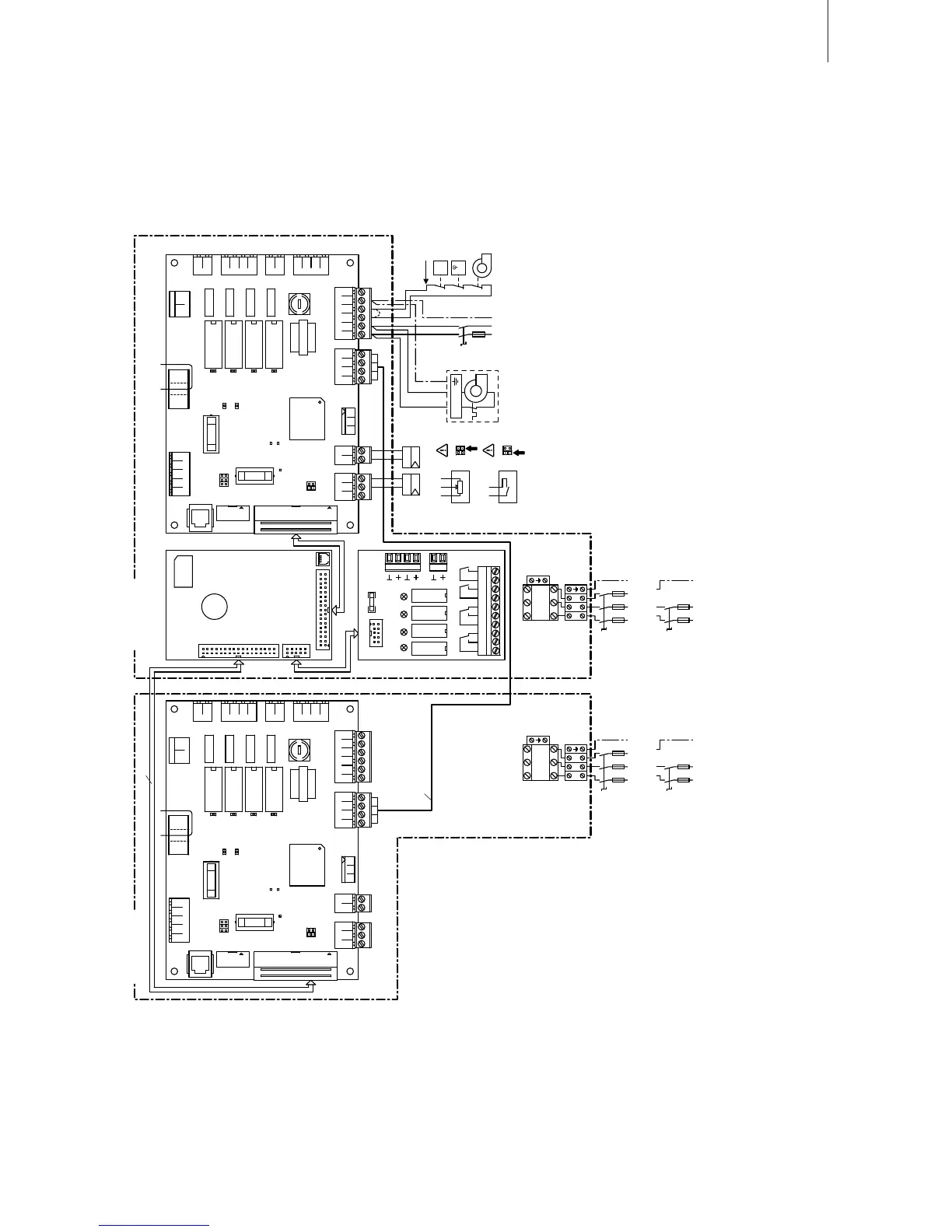

41

5.5 Electric installation

5.5.1 Wiring diagram Condair CP3 Basic/Pro

A1 Controller (active) or humidity sensor

A2 Controller (passive), set JP3 to position 5V

A3 On/Off controller, set JP3 to position 24V

A4 Limitation signal

BAT Backup battery CP3 Pro (CR2032, Lithium 3V)

B1 Ventilation interlock

B2 Safety humidistat

B3 Airow monitor

F1 Internal fuse “Power board” (6.3 A, slow acting)

F3 Internal fuse “Power board” control signal (315 mA, slow acting)

F4 Internal fuse “Power board” 24 VDC supply (V+) (315 mA, slow acting)

F5 External fuse heating voltage supply

F6 External fuse control voltage supply

H1 Remote operating and fault indication

J Short circuited, if no external monitoring devices are connected

J2 Link Up system “Power board”

JP1 Termination Link Up system

JP3 Jumper control signal

K External safety chain (230V/5A)

K1 Main contactor (for connecting the heating voltage supply to the unit)

M Ventilation unit

Q5 External service switch heating voltage supply

Q6 External service switch control voltage supply

X0 Connection terminal heating voltage (unit version Pro)

X1 Connection terminal control voltage

X6 Connection to module B

* supplied with

double units

4321

21

Analog Out

F1

100mA

Sensor Supply

Max. 60mA

Unit ONSteamServiceError

Fault Remote Board

1 2 3 4 5 6 7 8 9 10

H1

Q5

K1

X0

F5

L1 L2 L3

L1 L2 L3 PE

L1 L2 L3

Heating Module B

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q5

F5

L1 N PE

230 V/1~/50..60 Hz

Q5

K1

X0

F5

L1 L2 L3

L1 L2 L3 PE

L1 L2 L3

Heating Module A

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q5

F5

L1 N PE

230 V/1~/50..60 Hz

Module B Module A

Supply cable * (1.5 m)

CONTROL BOARD POWER BOARDPOWER BOARD

J3

DRIVER B

J2

FAULT REMOTE

J1 DRIVER A

J4

(RS485)

CP3 Card

Main unit

CR2032

BAT

REMOTE

LINK UP

EXTERNAL CON.CPU BOARD

D+ D– GND 5V 24V

X15

J2

PEPESC2SC1NL1

X1

F1 6.3 AT

INLET DRAIN CONTA.

L'NL'N

X4

CONT. SIGN.

GNDINV+

X10

JP3

L'N

X3

24V 5V

5V

24V

SAFETY CHAIN

CONTACTORDRAININLETSC SYSTEM

LEVEL SENSOR

GND

SWITCH

L1FUNL1SWNSW

X2

SC

L'N

X16

S1S2

LEVEL SENS.

CURRENT SENSOR

X5

MAIN SUPPLYMODULE B

PEP1NP

X6

LIM. SIGN.

GNDIN

EXT. SUP.

5V GND 24V

X11

X14

F4 315mAT

F3 315mAT

JP1

JP4

JP5

J1

J4

M

L1 N

+ –

P / PI

+ –

P / PI

A1 A4

140Ω...10kΩ

A2

On/Off

A3

GND

IN

V+

IN

V+

JP3

24V 5V

Q6

230 V/1~/50..60 Hz

L1 N PE

F6

B3

K

B2

B1

J

∆p

max.

JP3

24V 5V

from contactor to cylinder

REMOTE

LINK UP

EXTERNAL CON.CPU BOARD

D+ D– GND 5V 24V

X15

J2

PEPESC2SC1NL1

X1

F1 6.3 AT

INLET DRAIN CONTA.

L'NL'N

X4

CONT. SIGN.

GNDINV+

X10

JP3

L'N

X3

24V 5V

5V

24V

SAFETY CHAIN

CONTACTORDRAININLETSC SYSTEM

LEVEL SENSOR

GND

SWITCH

L1FUNL1SWNSW

X2

SC

L'N

X16

S1S2

LEVEL SENS.

CURRENT SENSOR

X5

MAIN SUPPLYMODULE B

PEP1NP

X6

LIM. SIGN.

GNDIN

EXT. SUP.

5V GND 24V

X11

X14

F4 315mAT

F3 315mAT

JP1

JP4

JP5

J1

J4

from contactor to cylinder

CPU cable * (1.5 m)

Loading...

Loading...