65

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

MENU 6: PROGRAMMABLE LOGIC AND TIMERS

CONTROL TECHNIQUES

3854 en - 03.2008 / b

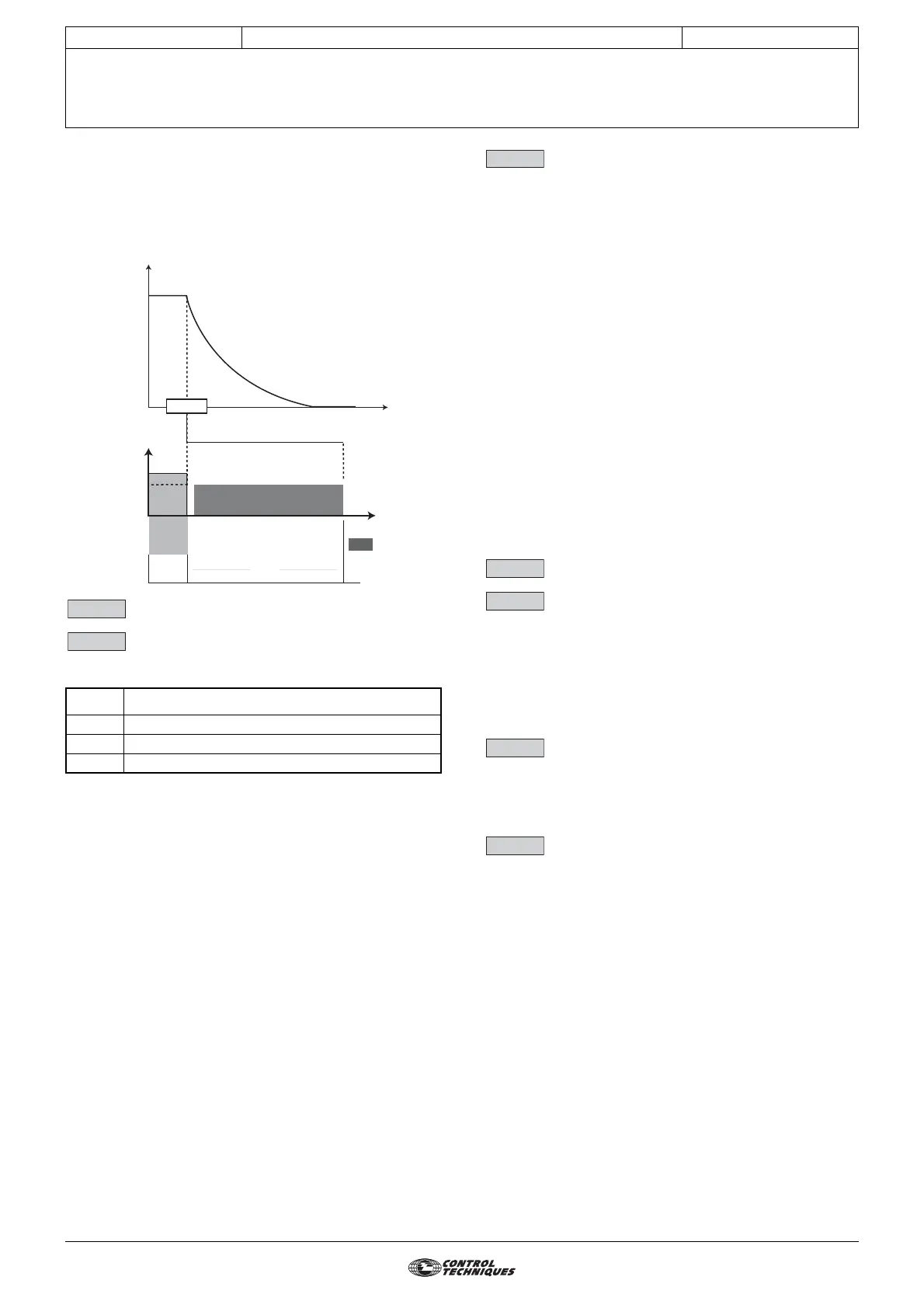

4 (Timed DC) (dC-t): Stop on DC injection with a set period

of time.

The drive decelerates the motor by setting a current defined

by parameter 6.06 for a time defined by parameter 6.07,

and then the drive displays "rdY". No run command can be

taken into account until "rdY" is displayed.

: Not used

: Mains loss mode

Adjustment range :0 to 2

Factory setting :0

0 (NO DETECTION) (diS): The drive does not take

account of mains supply breaks and continues to

operate while there is sufficient voltage on the DC bus.

1 (FULL STOP) (StOP): In the event of a mains supply break,

the drive will decelerate on a ramp, automatically calculated

by the drive, so that the motor feeds back energy to the drive's

DC bus and therefore continues to power its control

electronics. Upon return to normal conditions, deceleration

continues until the motor stops, but according to the

deceleration mode configured in 2.04.

2 (DELAYED STOP) (rd.th): In the event of a mains supply

break, the drive will decelerate on a ramp, automatically

calculated by the drive, so that the motor feeds back energy

to the drive's DC bus and therefore continues to power its

control electronics. Upon return to normal conditions, the

motor re-accelerates up to the reference speed.

: Start/stop logic select

Adjustment range :0 to 2

Factory setting :0

Used to choose one of 3 Run/Stop command and Direction of

rotation management modes.

0 (Run no latch) (Lchd) : DI2 terminal used as

FWD/Stop, DI3 terminal used as REV/Stop. Commands

given via latched contacts.

1 (Run Latched) (Puls) : DI2 terminal used as

FWD, DI3 terminal used as Stop, DIO1 terminal used as REV.

Commands given via pulsed contacts.

In this mode, the DI4 input can be assigned by the customer

but only as a latched contact and the stop command via DI3

cannot be reassigned. To change from FWD to REV or vice

versa, go via a stop command.

2 (Run-Fwd/Rev) (r.InP) : DI2 terminal used as Run/Stop,

DI3 terminal used to select the direction of rotation.

Commands given via latched contact.

These three configurations result in automatic assignment of

the digital inputs. If, within a configuration, an input is not used

by the application (no Reverse operation for example), the

corresponding input can be reassigned using menu 8.

Note: Modifications to 6.04 must be made with the drive

disabled.

: Not used

: DC injection braking level

Adjustment range :0 to 4.07

Factory setting :100.0%

This parameter defines the level of current used for DC

injection braking.

WARNING:

For efficient braking, the value of parameter 6.06 must

be 60% minimum.

: DC injection braking time

Adjustment range :0 to 25.0 s

Factory setting :1 s

This parameter defines the DC injection braking time when

6.01 is at 2, 3 or 4.

: Hold zero speed

Adjustment range :0 or 1

Factory setting :0

0 (Disabled) (OFF): The drive output is deactivated when

the speed is zero.

1 (Enabled) (On): The drive output remains active at zero

speed in order to hold the torque at standstill. The drive output

is deactivated when 6.08 changes to 0. While holding zero

speed, the display indicates "StoP".

Note: When the drive is in the "StoP" state and the Run

command has not been activated after one minute, the drive

returns to the "rdy" state (drive output deactivated).

6.03 Function

0 Transparent to micro-breaks

1 Deceleration down to stop

2 Deceleration until the mains returns

Motor

speed

Motor

current

t

Time

Braked stop

Motor

current

DC

injection

6.06

Stop

rdY

6.07

6.02

6.03

6.04

6.05

6.06

6.07

6.08

Loading...

Loading...