Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance RFC mode

Menu 3

All modes

Unidrive SP Advanced User Guide 71

Issue Number: 10 www.controltechniques.com

Any baud rate can be used when encoder comms is used with a SINCOS encoder to obtain the absolute position during initialization. When encoder

comms is used alone(EnDat or SSI selected with Pr 3.38) the time taken to obtain the comms position must be 160μs or less, otherwise the drive

initiates an Enc4 trip.

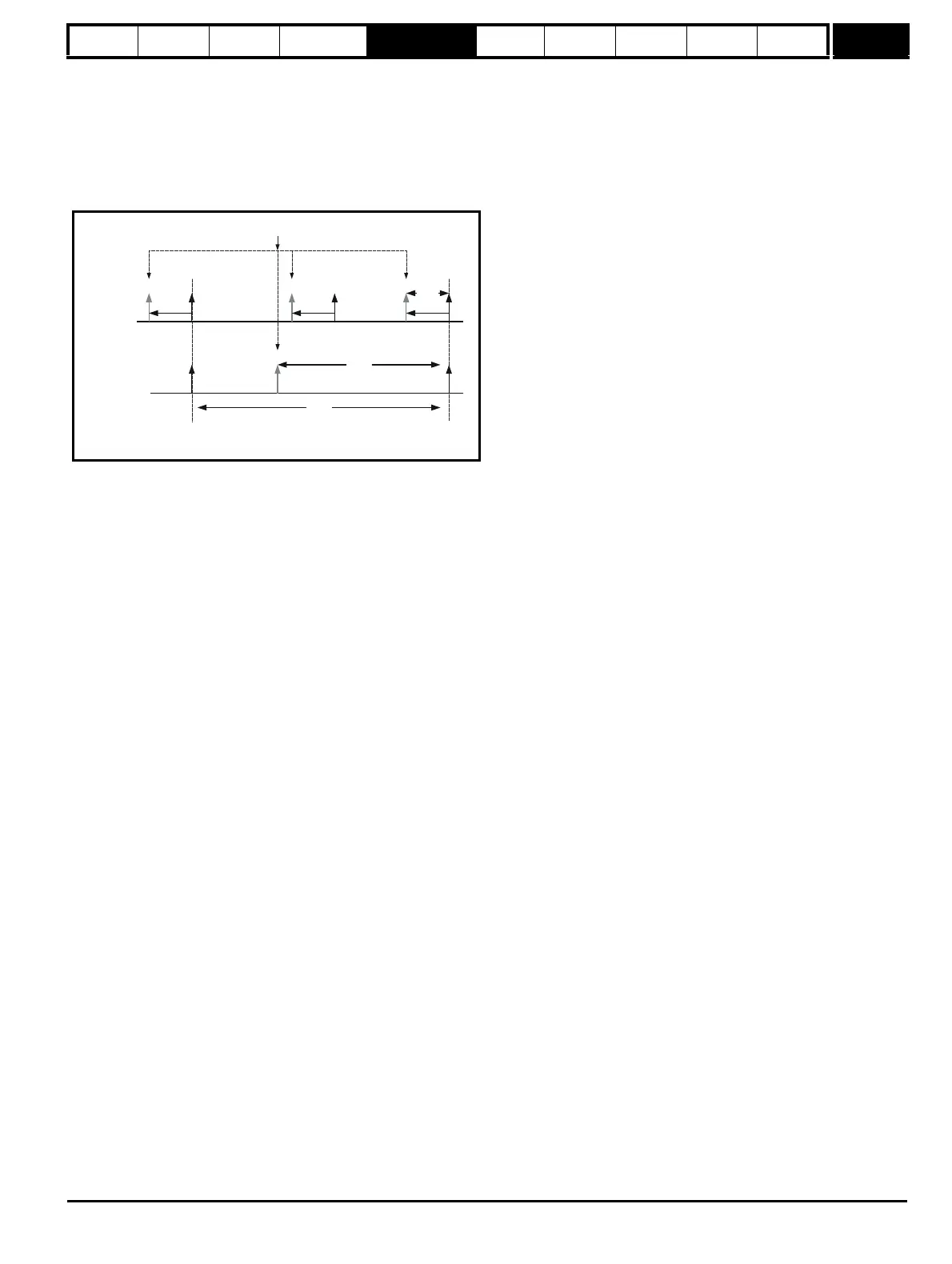

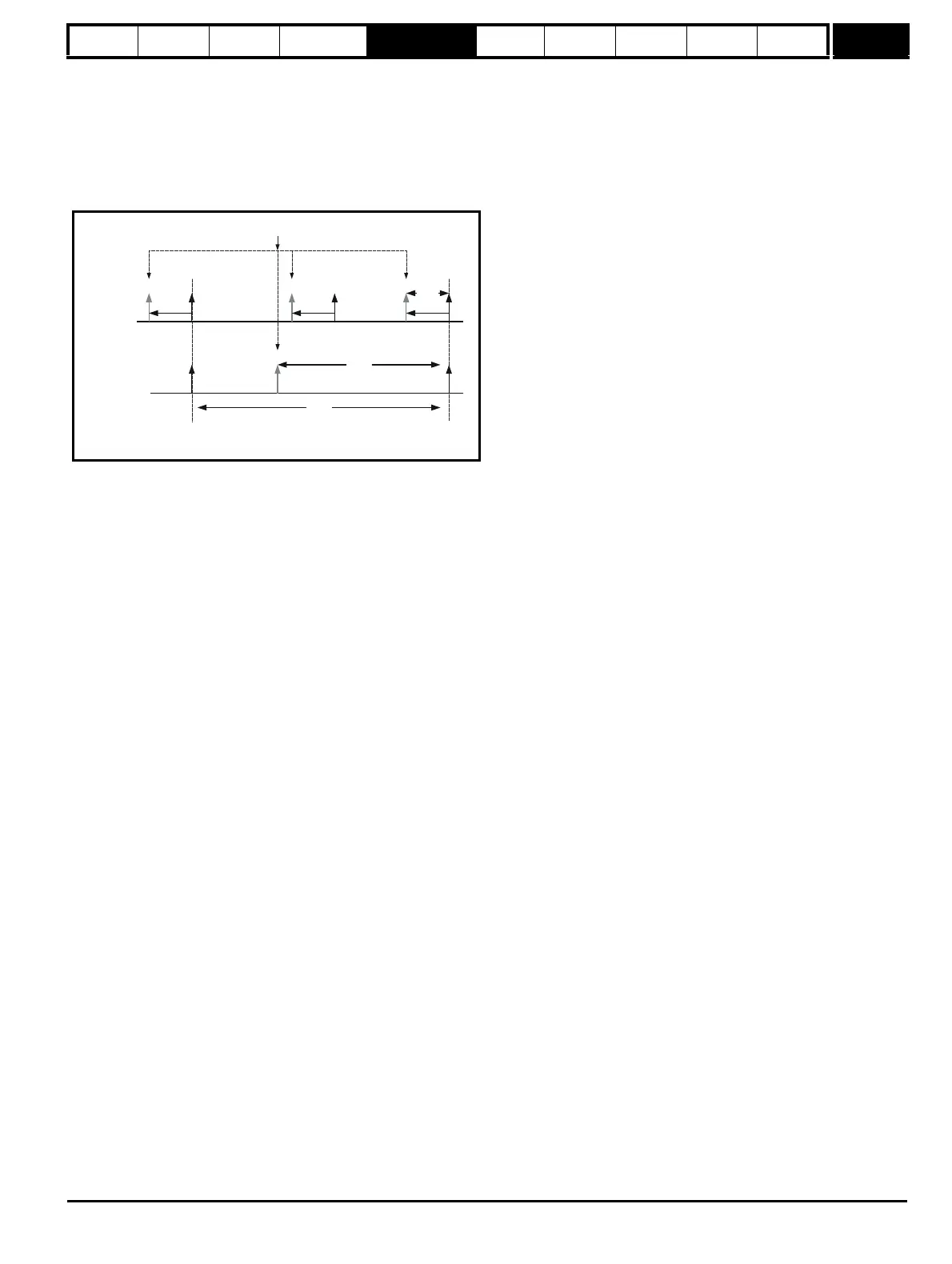

There is a delay obtaining the position from an encoder using comms alone. The length of this delay affects the sample rate and timing of the position

used by the drive for control and the position passed to Solutions Modules. If for an EnDat encoder the position within one turn can be obtained in

30μs and the whole comms message including CRC can be obtained in 60μs then fast sampling is used, otherwise slow sampling is used as shown

below. If for an SSI encoder the whole position can be obtained in 30μs fast sampling is used. In each case the position is sampled within the encoder

at the start of the comms message from the drive.

In the example the current/torque sampling rate is 4kHz, but this will change if a different switching frequency is selected. If fast sampling is used the

control position used to define the drive reference frame is obtained every current/torque control sample and the position passed to Solutions

Modules is obtained 20μs before the datum point where other types of encoders are sampled. If slow sampling is used both the control position and

the position passed to Solutions Modules is obtained 150μs before the datum. When fast sampling is used the delay introduced into the control

system by the encoder is less, and so a higher control system bandwidth will be possible. So that the position values from the encoder can be used in

a position control system compensation is provided for the delay in obtaining the position before it is made available to Solutions Modules or in the

drive position parameters so that it appears to have been sampled at the datum. This compensation is based on the delay (i.e. 20μs or 150μs) and

the change of position over the previous sample.

EnDat comms

The following equations are used by the drive to determine the time taken to obtain the position information from an EnDat encoder. These are based

on t

cal

≤ 5μs, where t

cal

is the time from the first clock edge of the position command message from the drive to the first clock edge when the encoder

responds as defined in the EnDat specification. This limit of 5μs may exclude a small number of EnDat encoders from being used by the drive as a

comms only feedback device. It is also assumed that t

D

≤ 1.25μs where t

D

is the data delay from the encoder as defined by the EnDat specification for

105m of cable. Although with higher clock rates shorter cables must be used, and t

D

will be less than 1.25μs, the calculation performed by the drive

always assumes t

D

=1.25μs. It should be noted that all values are rounded up to the nearest microsecond.

Command message time = t

command

= 10T or t

cal

whichever is the longest

Where: T = 1/Baud Rate, t

cal

= 5μs

Time for single turn position = t

command

+ t

D

+ (2 + Single turn resolution) x T

= t

command

+ t

D

+ (2 + Pr 3.35) x T

Where: t

D

= 1.25μs

Time for whole message including CRC = Time for single turn position + (Number of turns bits + 5) x T

= Time for single turn position + (Pr 3.33 + 5) x T

For example an encoder with 12 turns bits, 13 bit single turn resolution and a baud rate of 2M would give the following times:

Time for single turn position = 14μs (13.75μs rounded up)

Time for the whole message including CRC = 23μs (22.25μs rounded up)

A recovery time (tm) is specified for EnDat encoders, that is the time required between the end of one data transfer and the beginning of the next one.

If this time is not allowed between messages that transfer the position from the encoder, the encoder operates in continuous mode and the data from

the encoder will be incorrect and cause CRC errors. tm is nominally 20μs, but may vary from 10μs to 30μs (EnDat 2.1 specification). If tm is greater

than 23μs and 6 or 12kHz switching is used, which have a fast sample rate of 83μs, it is possible for the time allowed for tm to be too short. Therefore

if 6 or 12kHz switching are used the total message transfer time should not exceed 53μs unless tm can be guaranteed to be less than 30μs by a

suitable margin.

Slow

Sampling

Fast

Sampling

250 s

μ

Datum

Point

Datum

Point

150 s

μ

20 s

μ

Start of comms messages and encoder position sampling point

Loading...

Loading...