Troubleshooting Proline Promag 53 MODBUS RS485

102 Endress+Hauser

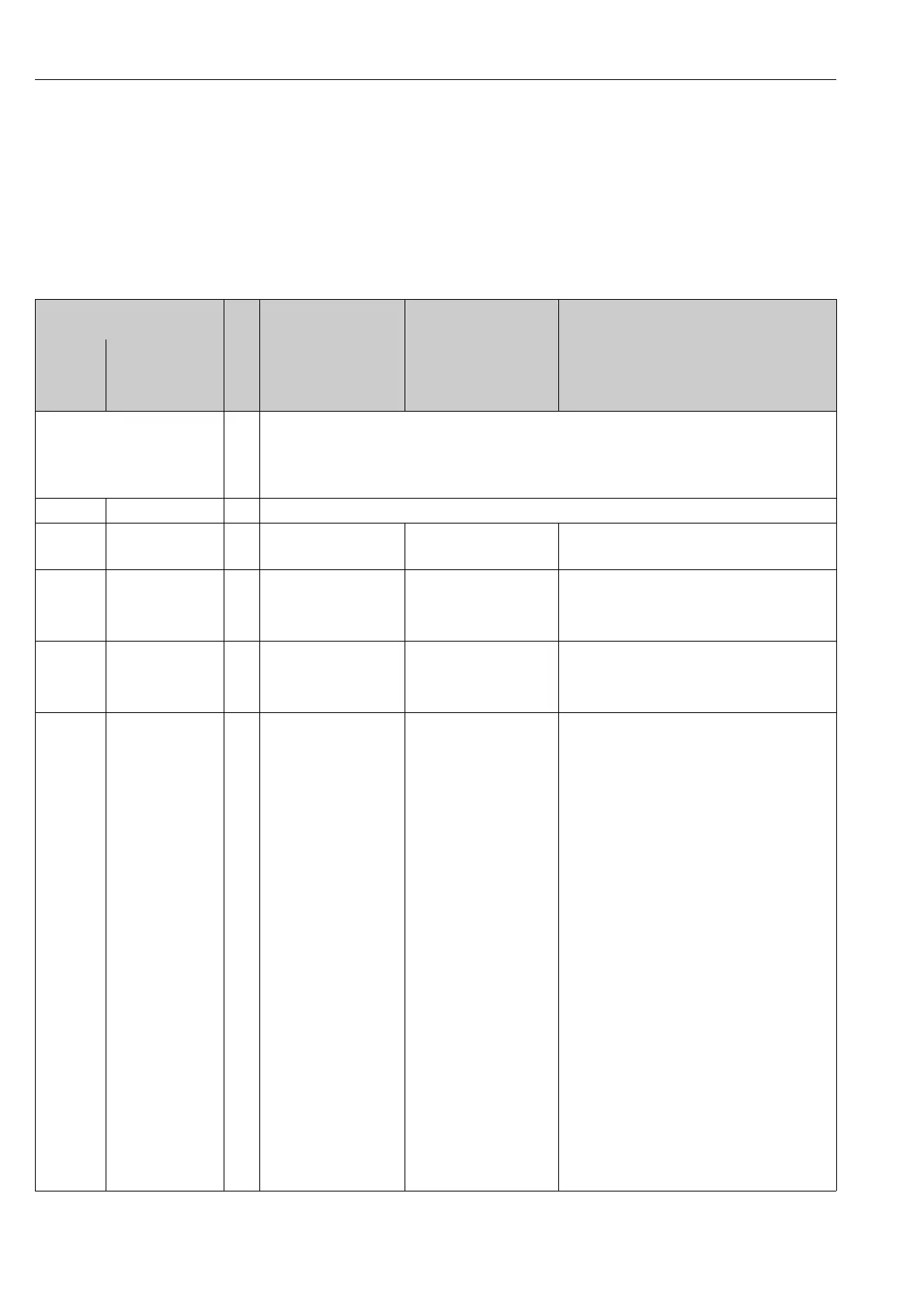

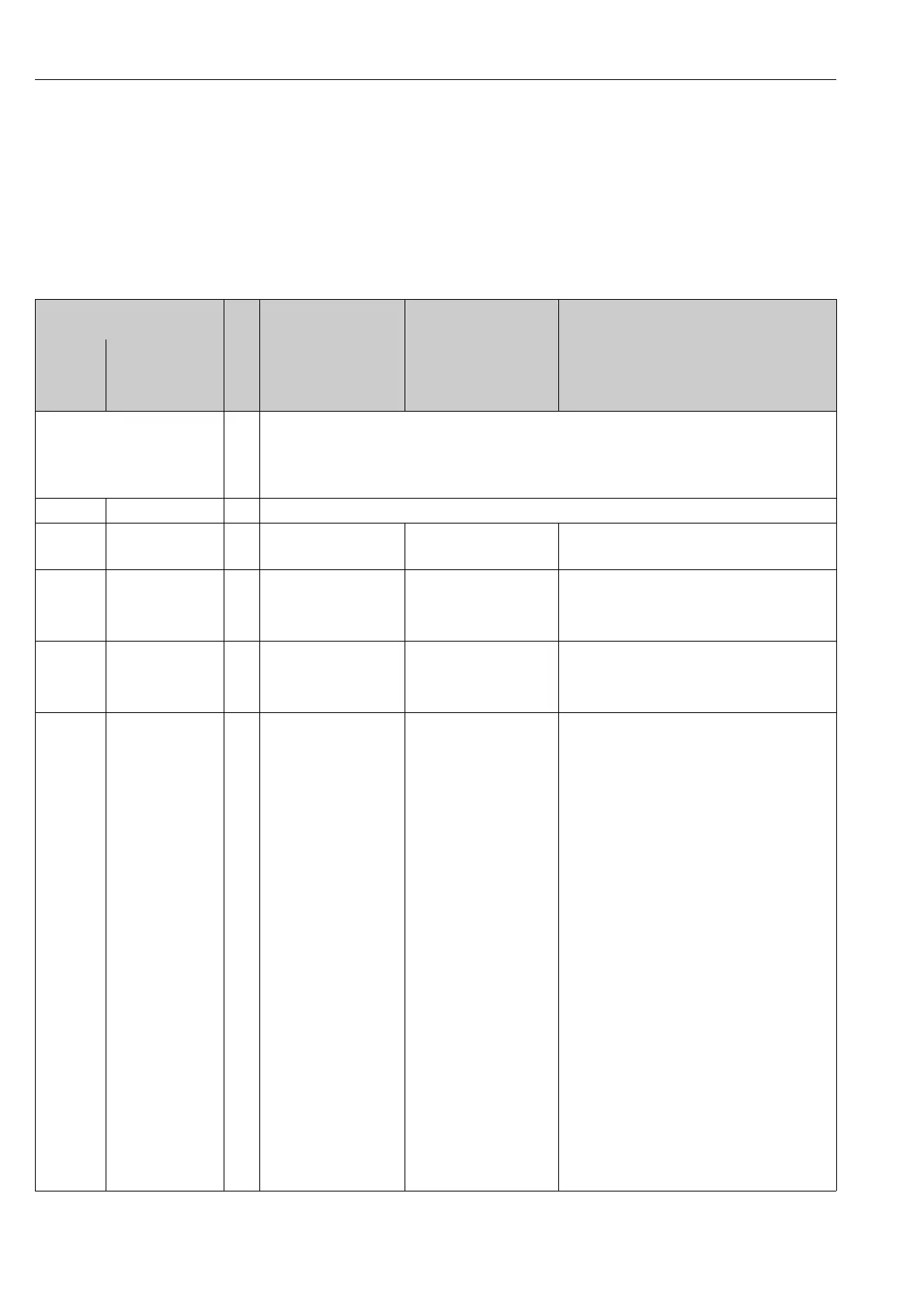

9.3 Process error messages

Process errors can be defined as either "Fault" or "Notice" messages and can thereby be weighted

differently. You can define messages in this way with the aid of the function matrix

(→ "Description of Device Functions" manual).

!

Note!

• The listed error message types below correspond to the factory setting.

• See the information on → ä 60

MODBUS No. Device status message

(local display)

Cause Remedy / spare part

Register:

6859

Data type:

Integer

Register:

6821

Data type:

String (18 byte)

Response to a fault message:

The value "NaN" (not a number) is

transmitted to the MODBUS master

instead of the current measured

value.

Depicted on the local display:

S = System error

$ = Fault message (with an effect on the inputs and outputs)

! = Notice message (without any effect on the inputs and outputs)

1SYSTEM OK- There is no error present in the device

52 EMPTY PIPE 401 P: EMPTY PIPE

$: # 401

Measuring tube partially filled

or empty.

1. Check the process conditions of the plant

2. Fill the measuring tube

55 EPD ADJ N.OK 461 P: ADJ N. OK

!: # 461

EPD/OED adjustment not

possible because the fluid's

conductivity is either too low

or too high.

The EPD/OED function cannot be used with fluids of

this nature.

57 EPD FULL = EMPTY 463 P: FULL = EMPTY

$: # 463

The EPD/OED adjustment

values for empty pipe and full

pipe are identical, therefore

incorrect.

Repeat adjustment, making sure procedure is correct.

→ ä 91

97 > BATCH TIME 471 P: > BATCH TIME

$: # 471

The maximum permitted

batching time was exceeded.

1. Increase flow rate.

2. Check valve (opening).

3. Adjust time setting to changed batch quantity.

!

Note!

If the errors listed above occur, these are displayed in

the Home position flashing continuously.

•General:

These error messages can be reset by configuring

any batching parameter. It is sufficient to confirm

with the OS key and then the F key.

• Batching via status input:

The error message can be reset by means of a pulse.

Another pulse then restarts the batching.

• Batching via operating keys (soft keys)

The error message is reset by pressing the START

key. Pressing the START key a second time starts

the batching process.

• Batching via the BATCHING PROCESS function

(7260):

The error message can be reset by pressing the

STOP, START, HOLD or GO ON keys. Pressing the

START key a second time starts the batching

process.

Loading...

Loading...