Installation Proline Promag 53 MODBUS RS485

32 Endress+Hauser

3.3.3 Installing the Promag H sensor

The sensor is supplied, as per your order, with or without installed process connections. Installed

process connections are screwed onto the sensor using 4 or 6 hexagonal-headed bolts.

"

Caution!

Depending on the application and the length of the pipe, the sensor must be supported or more

securely mounted if necessary. Particularly when using process connections made of plastic, it is

essential that the sensor be mounted securely. A wall mounting kit for this purpose can be ordered

separately as an accessory from Endress+Hauser (→ ä 94).

a0004301

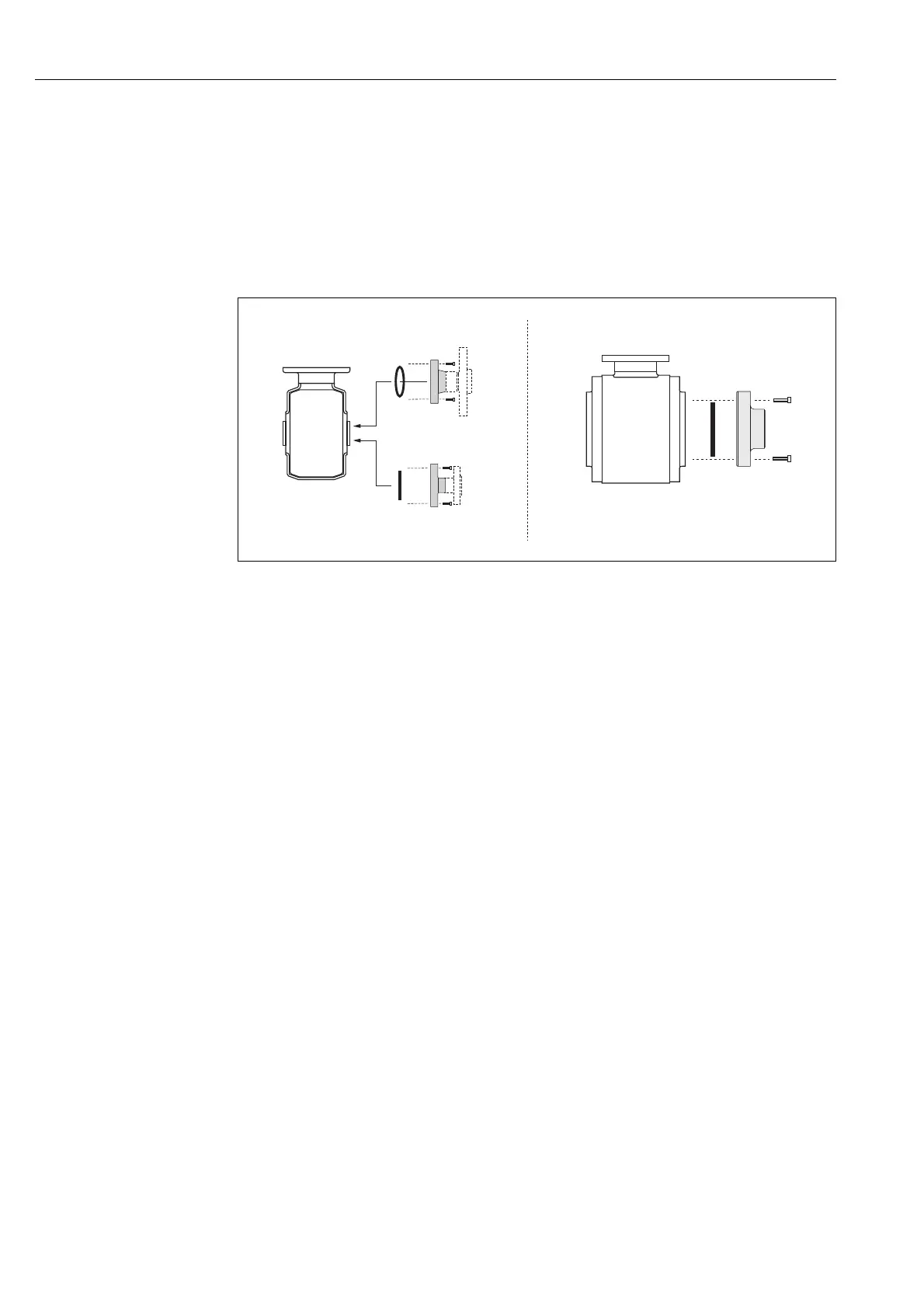

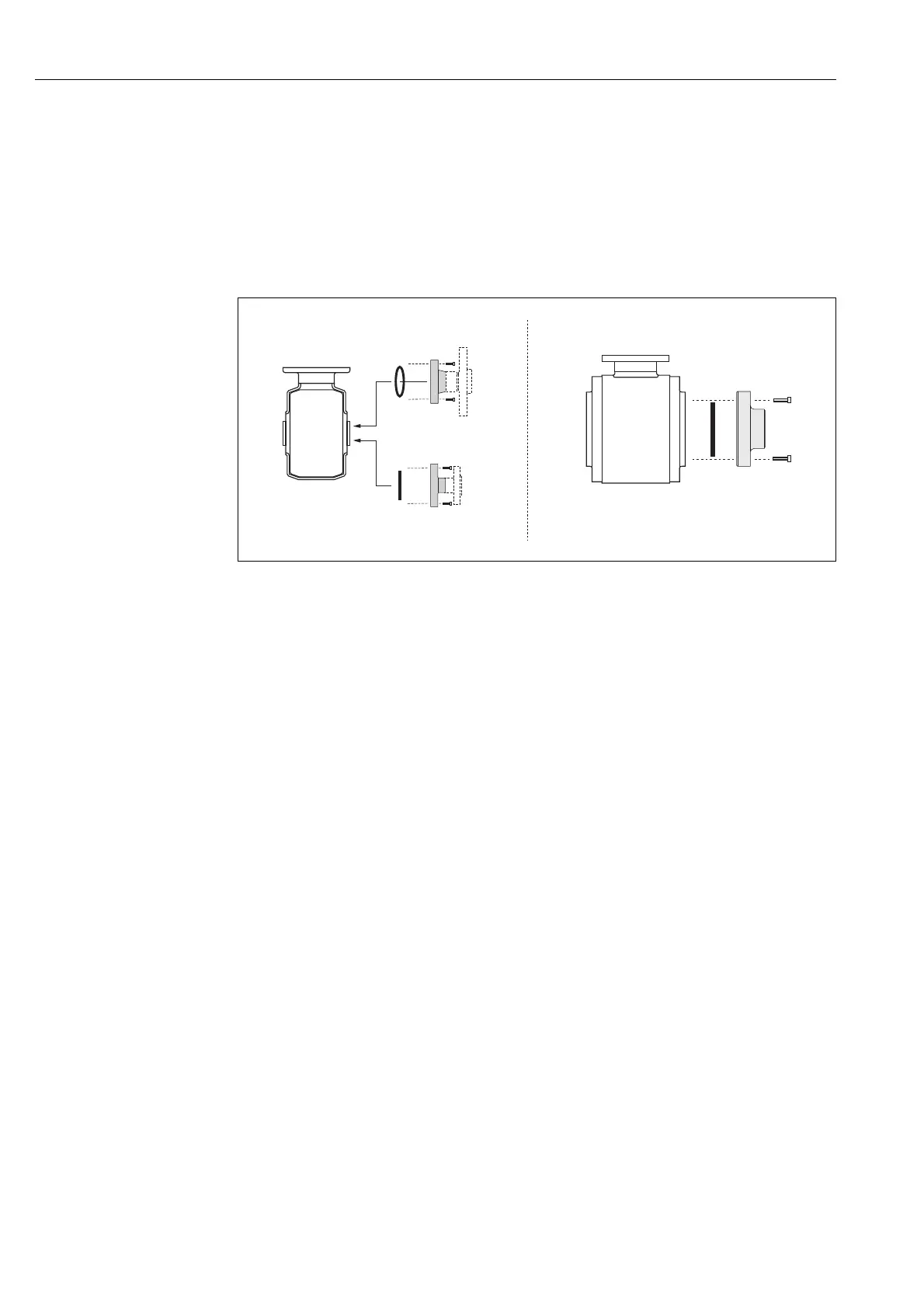

Fig. 20: Promag H process connections; DN 2 to 25 / DN 40 to 100 (1/12" to 1" / 1 ½" to 4")

A = DN 2 to 25 (1/12" to 1") / Process connections with O-ring

Weld nipple (DIN EN ISO 1127, ODT / SMS), flange (EN (DIN), ANSI, JIS), flange made of PVDF (EN (DIN), ANSI, JIS),

external thread, internal thread, hose connection, PVC adhesive fitting

B = DN 2 to 25 (1/12" to 1") / Process connections with aseptic molded seal

Weld nipple (DIN 11850, ODT / SMS), clamp (ISO 2852, DIN 32676, L14 AM7),

coupling (DIN 11851, DIN 11864-1, SMS 1145), flange DIN 11864-2

C = DN 40 to 100 (1 ½" to 4") / Process connections with aseptic molded seal

Weld nipple (DIN 11850, ODT / SMS), clamp (ISO 2852, DIN 32676, L14 AM7),

coupling (DIN 11851, DIN 11864-1, ISO 2853, SMS 1145), flange DIN 11864-2

Seals

When mounting the process connections, please ensure that the relevant seals are clean and

properly centered.

"

Caution!

• In the case of metallic process connections, the screws must be fully tightened. The process

connection forms a metallic connection with the sensor, which ensures a defined compression of

the seal.

• In the case of process connections made of plastic, the maximum screw tightening torques for

lubricated threads (7 Nm / 5.2 lbf ft) must be adhered to. In the case of plastic flanges, a seal must

always be used between the connection and the counterflange.

• Depending on the application, the seals should be replaced periodically, particularly when molded

seals (aseptic version) are used!

The interval between replacements depends on the frequency of the cleaning cycles and on the

temperatures of the fluid and the cleaning process. Replacement seals can be ordered as an

accessory at a later stage → ä 94.

A

B

C

Loading...

Loading...