EPSON Stylus COLOR 440, 640, and 740 Chapter 6 Maintenance

142

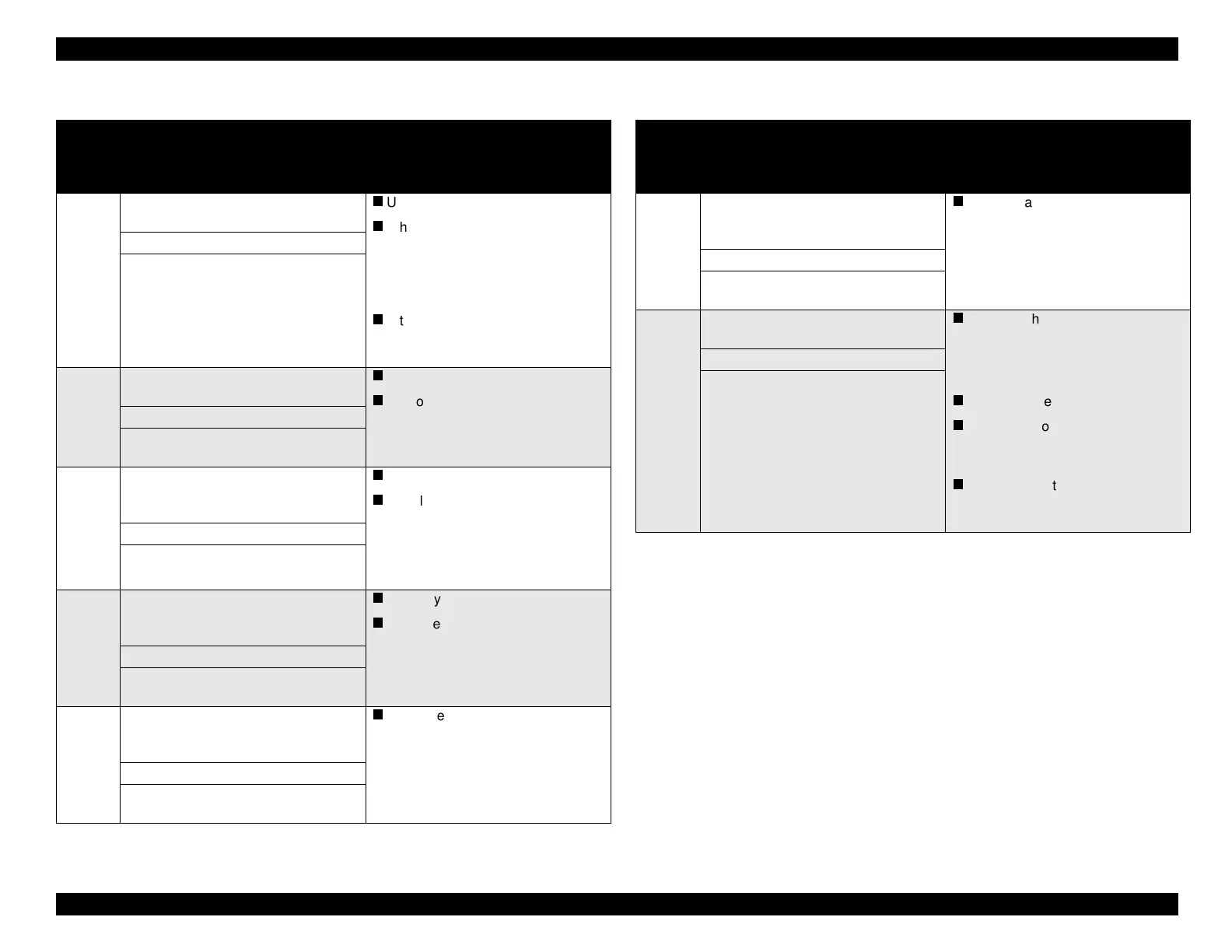

Fig 6-5,

#6

Lubrication Point:

the left and right

paper feed roller bushings

Use a syringe to apply the grease.

When you apply the grease to the

right bushing, apply it from the

paper path side and wipe off any

excess grease that comes out

near the capping assembly.

After applying the grease, rotate

the paper feed roller to distribute it

evenly on the bushings.

Lubricant Type:

G-26

Lubrication Amount:

a small

amount equivalent to an area about

1/8 inch (3 mm) in diameter

Fig 6-5,

#7

Lubrication Point:

the left and right

eject roller bushings

Use a syringe to apply the grease.

Do not get grease into the paper

path.

Lubricant Type:

G-26

Lubrication Amount:

apply a small

amount evenly inside the bushings

Fig 6-6,

#8

Lubrication Point:

where the timing

belt tensioning mechanism slides

against the top frame

Use a syringe to apply the grease.

After lubricating it, make sure the

tensioning mechanism slides when

pressure is applied only from the

spring.

Lubricant Type:

G-26

Lubrication Amount:

about 1/16

inch (2 mm) long for each point

Fig 6-7,

#9

Lubrication Point:

the hole in the

right side of the ASF frame that holds

the ASF drive shaft

Use a syringe to apply the grease.

Do not let grease come into contact

with the rubber rollers in the Auto-

Sheet Feeder (ASF).

Lubricant Type:

G-26

Lubrication Amount:

apply lubricant

evenly inside the hole

Fig 6-7,

#10

Lubrication Point:

where the

hopper and the hopper release cams

come into contact

If any grease gets inside the ASF,

wipe it off completely.

Lubricant Type:

G-26

Lubrication Amount:

apply lubricant

evenly to the contact points

Table 6-2. Lubrication Points (continued)

Figure

and

Callout

No.

Lubrication Points, Type, and

Amount

Remarks

Fig 6-3,

#11

Lubrication Point:

the hole in the

left side of the ASF frame where gear

34 is inserted

If any grease gets inside the ASF,

wipe it off completely.

Lubricant Type:

G-26

Lubrication Amount:

apply lubricant

evenly inside the hole

Fig 6-1,

#12

Lubrication Point:

the oil pad in the

carriage unit

Lubricate the oil pad only if:

1. You’re replacing the carriage

assembly.

2. You’re replacing the oil pad.

Use a syringe to apply the oil.

Wait for the oil to soak evenly into

the pad before installing the pad in

the carriage unit.

If you accidentally apply too much

oil to the pad, throw it away and

use a new one.

Lubricant Type:

O-12

Lubrication Amount:

0.7 cc

NOTE: This is the amount that should

be applied to a new pad when you’re

replacing an old one.

Table 6-2. Lubrication Points (continued)

Figure

and

Callout

No.

Lubrication Points, Type, and

Amount

Remarks

Loading...

Loading...