02-2023 6095 00 25

OPERATION

The following paragraphs describe the

operation of the main components of the

machine.

BREW UNIT

Whenever you power on the machine or

make a request for dispensing, the brew

unit will make a complete rotation before

performing the brew cycle to make sure that

the device will occupy the initial position.

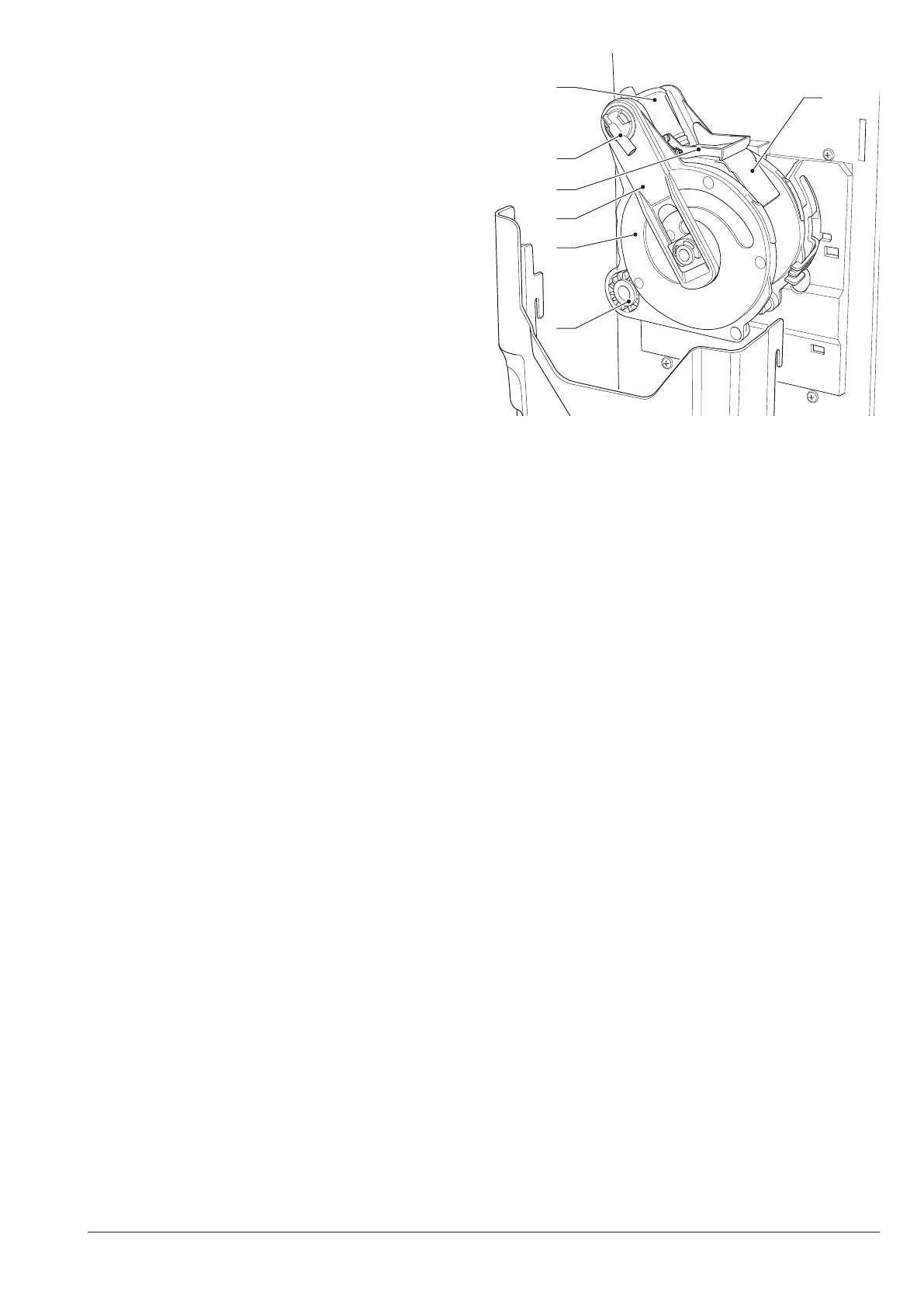

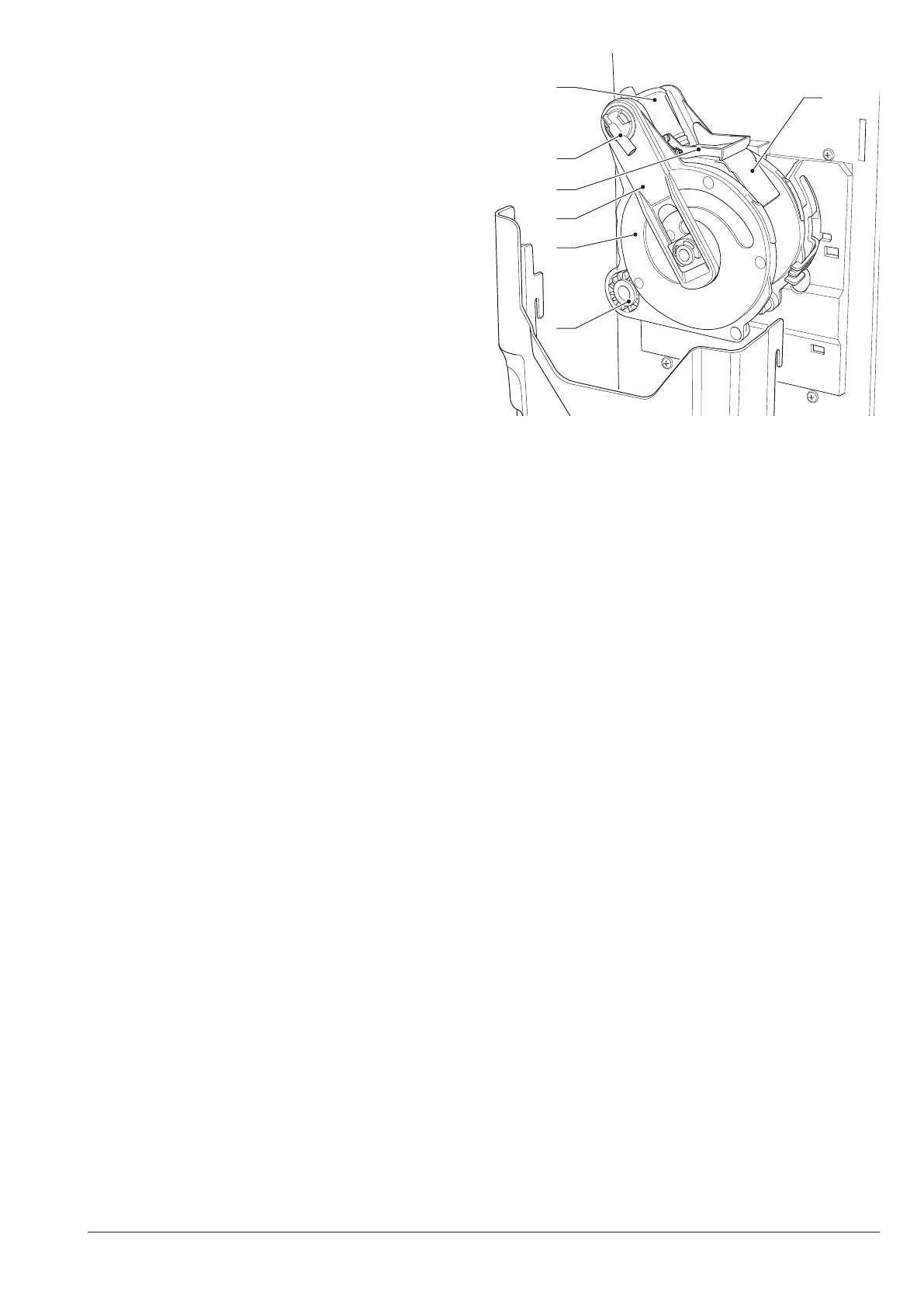

DispENsiNg cyclE

Whenever you require a coee-based

selection, the grinder will operate to ll the

coee doser chamber.

When the doser is full, the ground dose is

released into the brewing chamber verti-

cally arranged inside the coee unit.

The ratio-motor engaged onto the pinion

(6) will rotate the cranks (5) that will cause

the brewing chamber to rotate by 30°.

The upper piston (1) will align with the

brewing chamber and move down inside

it. The stop position of the piston for brew-

ing will depend upon the quantity of ground

product in the chamber.

At the end of the coee dispensing cycle,

the upper piston will move down to me-

chanically compress the used coee dose,

thus helping water in excess to come out

of the third way of the dispensing solenoid

valve.

2

3

4

5

1

6

7

Fig. 21

1. Upper piston

2. Coffee outlet nozzle

3. Scraper

4. Connecting rods

5. Cranks

6. Pinion

7. Waste coffee chute

At the end of the cycle, the ratio-motor is

driven in the opposite direction, thus lifting

the upper piston and rotating the brewing

chamber to the unload side, opposite the

dispensing side; the lower piston (8) will

move up.

After having reached the unload position,

the ratio-motor will reverse the direction of

rotation once again, thus moving the brew-

ing chamber back into its standby position.

The scraper (3) will retain and drop the cof-

fee dose whereas the lower piston (8) will

move back into its standby position.

Loading...

Loading...