4 Dimension reference system

Festo – GDCP-CMMS/D-FW-EN – 1404NH – Engli sh 77

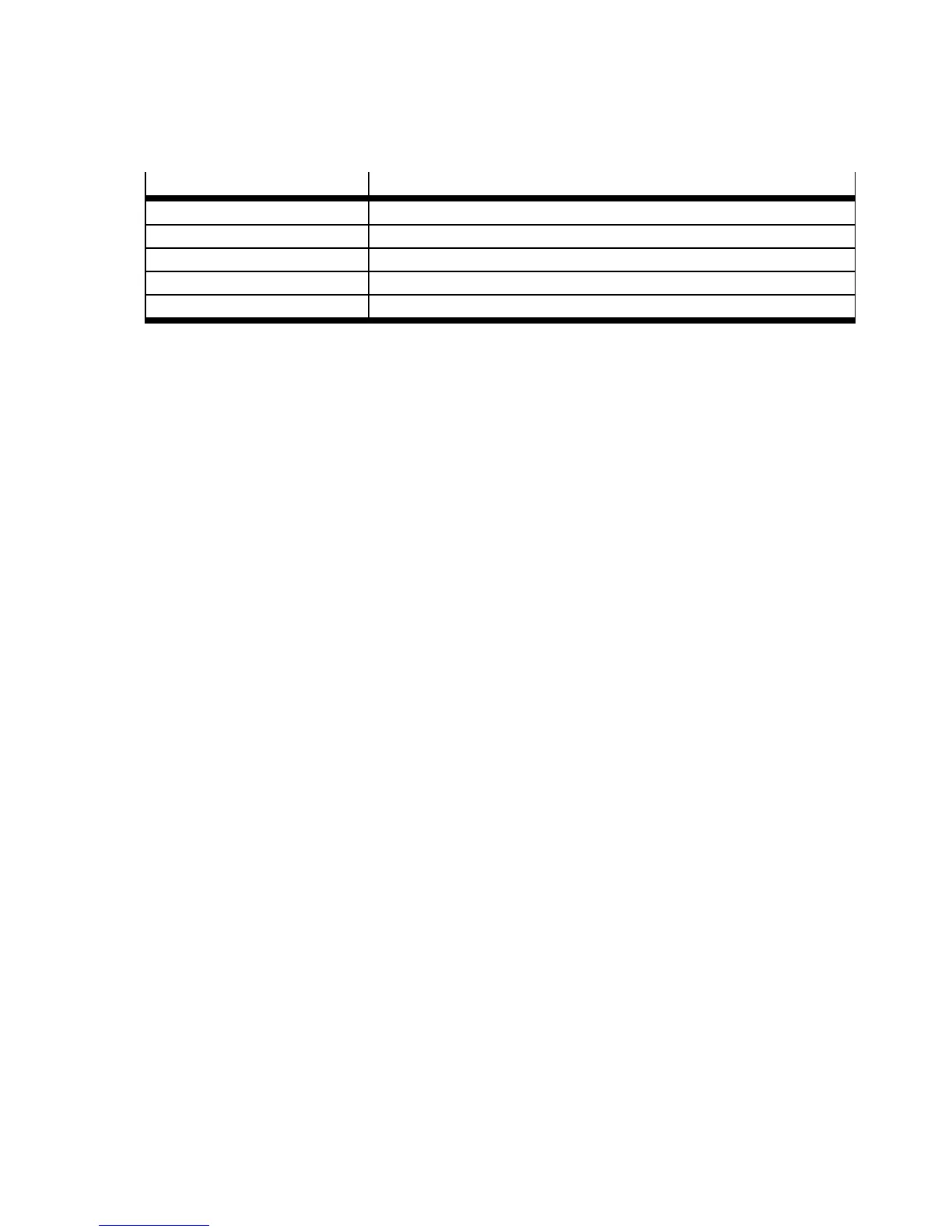

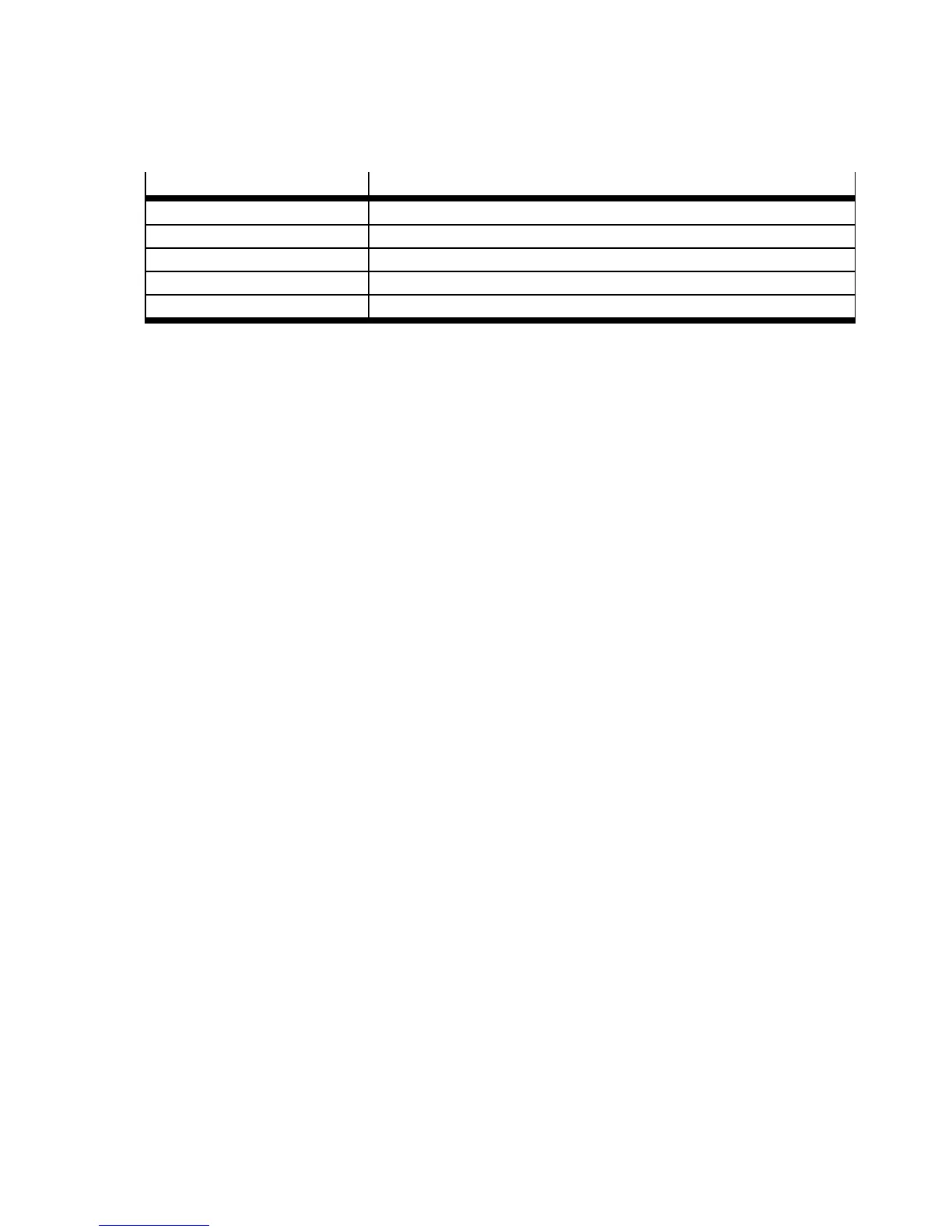

4.2 Calculation rules for the measuring system

Point of reference Calculation rule

Axis zero point AZ =REF+ a

Projec t zero point PZ =AZ+ b =REF+ a+b

Negative software end position SLN =AZ+ d =REF+ a + d

Positive software end position SLP =AZ+ e =REF+ a + e

Target position/actua l position TP/AP =PZ+ c =AZ+ b + c =REF+ a + b+c

Tab. 4.3 Calculation rules for the measuring system

4.3 Limit switch (hardware) and software end position

4.3.1 Limit switch LSN/LSP (hardware)

If the axis (linear/rotative) is restricted, the negative limit switch (LSN) and the positive limit switch

(LSP) is supported. These limit the absolute effective stroke/effective positioning range of the drive.

The switching function “NC contact” or “N/O c ontact” can be parameterised dependent on the limit

switch type.

One limit switch active:

If one of the limit switch positions is reached, the drive is braked with the reaction parametrised in the

FCT error management “PS off/Qstop/Warn” of message “430/431” page 208.

After that, the positioning direction of the respective active limit switch is blocked. That is, the drive can

only be run in the positioning direction of the inactive limit switch.

Both limit switches active:

If both limit switches are active simultaneously, the drive is braked with the reaction parametrised in

the FCT error management “PS off/Qstop/Warn” of message “439” (the message “439” is configured

via m essage “430”) page 208.

4.3.2 Software end position SLN/SLP

If the axis is restricted, the negative software end position (S LN) and the positive software end position

(SLP) for limitation of the working stroke/working positioning range can also be parameterised relative

to the axis zero point between the limit switc hes ( hardware). As with the LSN/LSP limit switc hes (hard-

ware), here, too, the positioning range is blocked when the software end position is blocked. In addi-

tion, before the software end position is reached, braking with the stop deceleration “limit switch” is

started so that the position of the software end position is not overtravelled.

Before starting, a c heck is made whether the target positions of the positioning records lie between the

software end positions SLN/SLP. If a target position lies outside this range, the positioning record is not

executed and the reaction parameterised in the FCT error management of messages “400…403” is

carried out.

Loading...

Loading...