68

When the TR 52-1 remote control pedal unit is used, the machine

will automatically switch over to 2-step operation.

(See description of TR 52-1 on p. 46, 47)

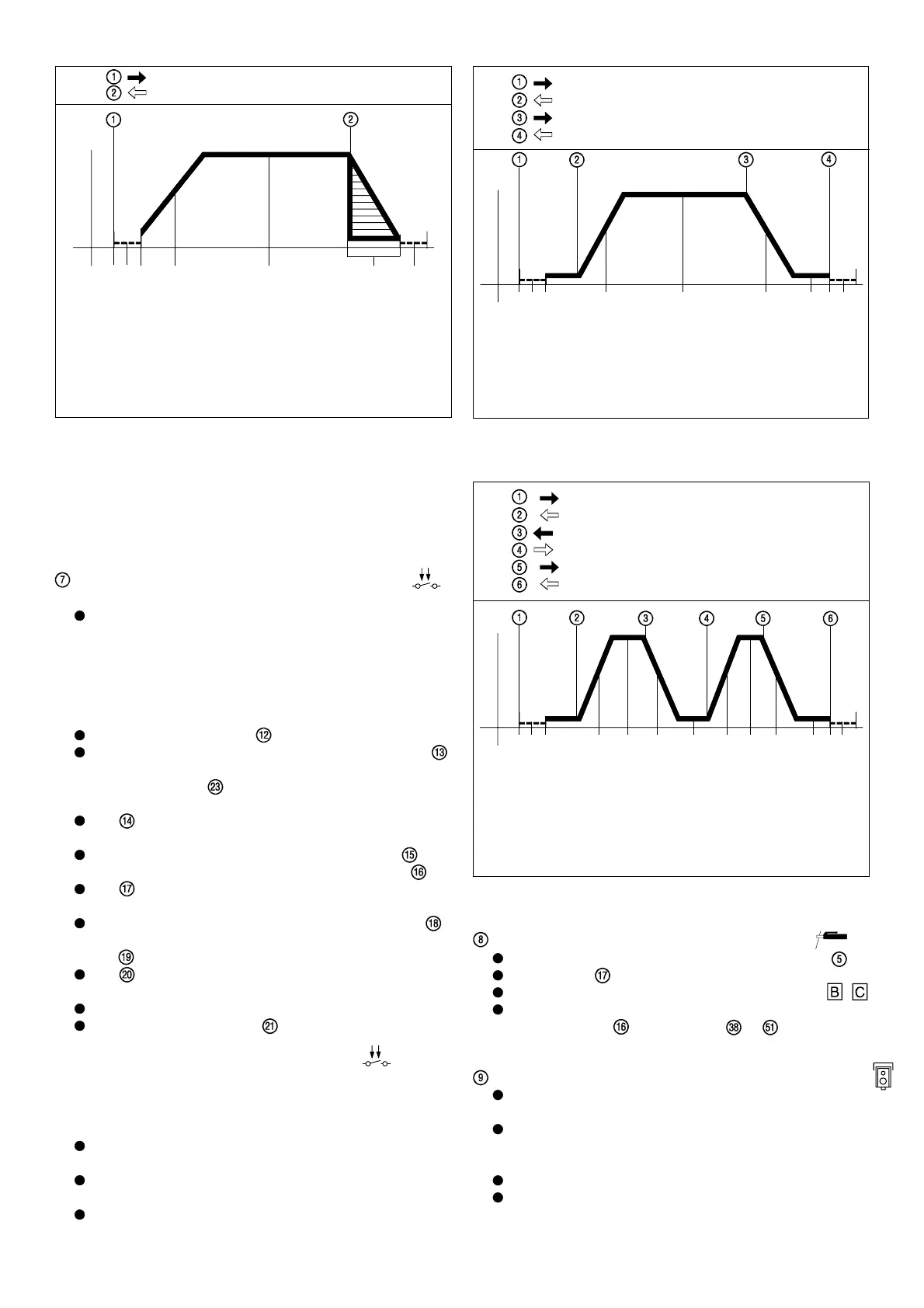

Release the torch trigger

Pull back torch trigger and hold it down

I

H

I

O

Start of cycle

Gas pre-flow time

Arc ignitions with

start arc ignition I

S

End of welding

via down-slope

to crater fill current I

E

Gas post-flow-time

t

Welding with

pre-set main current I

H

Current rise via up-slope

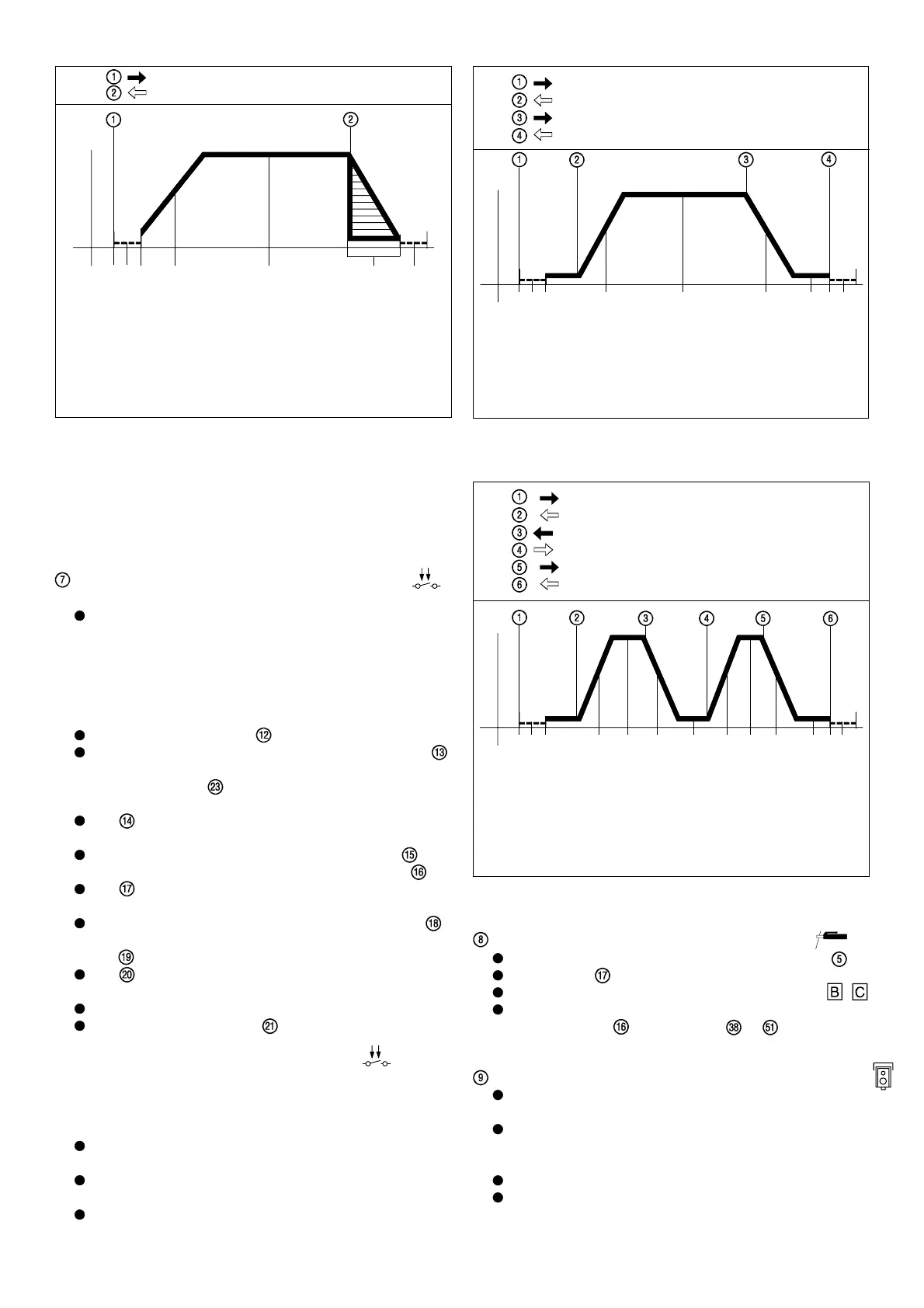

Pull back torch trigger and hold it down

Release the torch trigger

Pull back and hold down the torch trigger once again

Release the torch trigger

t

Start of cycle

Gas pre-flow time

Current rise

via up-slope

Current drop

via down-slope

Gas post-flow-time

End of welding

Crater fill current I

E

Arc ignitions with

start arc ignition I

S

O

I

I

H

I

S

I

E

Welding with pre-set

main current I

H

Fig. 16 Functional sequence in 2-step operating mode Fig. 17 Functional sequence in 4-step operating mode

O

I

I

S

I

H

I

E

t

I

H

I

E

Start of cycle

Gas pre-flow time

Arc ignition with

start-arc I

S

Current rise

via up-slope

Current drop via down-

slope to crater-fill current I

E

Current rise again

via up-slope

Crater-fill current I

E

Main current I

H

Gas post-flow time

Crater-fill current I

E

End of welding

Welding with pre-set

main current I

H

Current drops again

via down-slope

Pull back torch trigger and hold it down

Release the torch trigger

Push trigger forward and hold it

Release the torch trigger

Pull back and hold down the torch trigger once again

Release the torch trigger

Fig. 18 Functional sequence in 4-step operating mode, with facility for lowering the

welding current without any break in welding.

LED INDICATOR for manual electrode welding

Symbol is selected with the function selector switch

LED indicator lights up (for main current I

H

)

le courant de soudage est livré aux prises de courant ,

Le courant de soudage peut être réglé soit internement par

current regulator

, or via the dial or on the

TP3 / TP4-SP remote control unit.

CONNECTING SOCKET (10-pole) for remote control unit

Plug the remote control cable plug into the socket, the right

way round, and tighten the swivel nut

The machine automatically recognizes the fact that the

remote control unit has been plugged in - there is thus no

need for any internal/external switchover.

The desired welding current is set on the remote control unit.

The short-circuit-proof supply voltage to the remote control

units protects the electronics in the event of any damage to

the remote control cable.

LED INDICATOR for 4-STEP operation / variant 1

called up via TIG torch trigger (Fig. 17)

Field of use: manual or automatic welding operations in

which settable parameters such as gas pre-flow, start arc,

current rise time, main current, current drop time, crater fill

current and gas post-flow time are the precondition for a

fault-free welded join.

Functional sequence:

1.Pull back the torch trigger and hold it down

Gas pre-flow time elapses

The arc ignites at the start-arc current value I

s

set by dial ,

either with or without HF, depending on the position of the

HF selector switch .

(N.B. HF switches off automatically following arc ignition).

LED lights up.

2.Release torch trigger

The current rises over the set speed (up-slope, dial ) until

it reaches the value set for the main current I

H

(dial )

LED lights up.

3.Pull back and hold down the trigger once again

The current falls over the set speed (down-slope, dial )

until it reaches the value set for the crater-fill current I

E

(dial ) = END CRATER IS FILLED !

LED lights up.

4.Release torch trigger

Arc goes out

Gas post-flow time elapses

Description of 4-step operation / variant 2

This variant allows the welding current to be lowered from the

main current to the crater-fill current and back again, with no

break in welding. (Fig. 18)

Practical tips:

The functional sequence described in Fig. 18 is only possible

in the 4-step operating mode.

A current drop with no break in the welding sequence is only

possible if the main current is activated.

If the trigger is accidentally pushed forward when the

machine is in open circuit, no ignition is possible.

Loading...

Loading...